To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

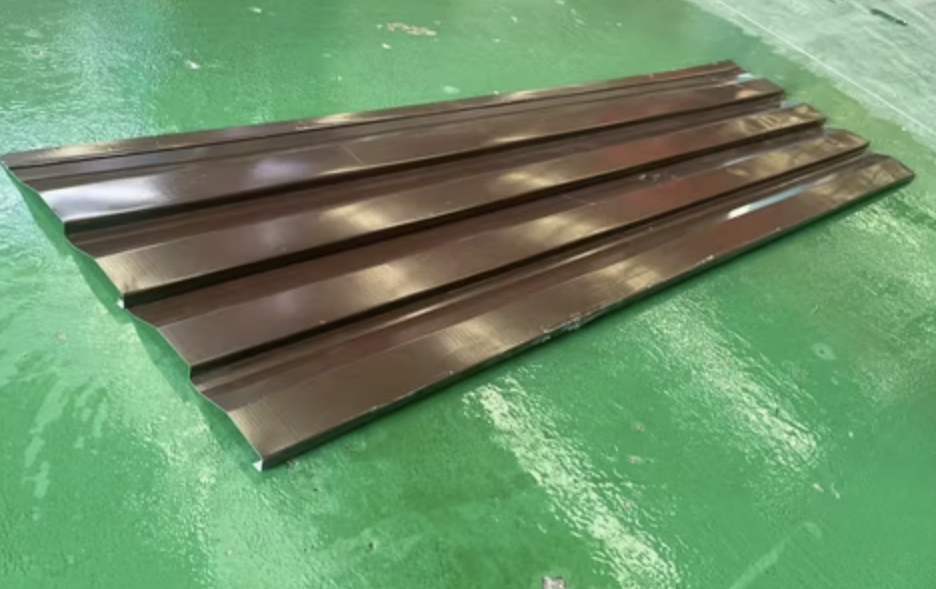

Roof Tile Roll Forming Machine - United Arab Emirates

The Roof Tile Roll Forming Machine is a high-performance solution designed to produce high-quality metal roof tiles for construction projects in the United Arab Emirates. This machine is engineered with precision to ensure durability, efficiency, and a long service life. With advanced forming technology and robust construction, it is the ideal choice for companies in the roofing, construction, and steel fabrication industries.

This machine is fully automated and capable of processing PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) materials, making it a versatile option for various roofing applications. It is designed to handle material thicknesses of 24/26 gauge (0.4-0.6 mm), ensuring the production of durable, aesthetically pleasing roof tiles.

Each machine is custom-built to meet specific profile and machine requirements, ensuring that customers receive a tailored solution for their projects. The machine is shipped directly from our manufacturing partner to the customer's location in the UAE, with warranty and ongoing maintenance support included.

The Roof Tile Roll Forming Machine is widely used in:

| Specification | Details |

|---|---|

| Raw Material | PPGI, PPGL |

| Material Thickness | 24/26 Gauge (0.4-0.6 mm) |

| Machine Frame | 350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate |

| Material Of Rollers | High Grade 45# Forged Steel, Chromed Treatment (Chrome Thickness: 0.05 mm) |

| Forming Stations | 18 Rows |

| Rolling Type | Separate Rolling Design Concept (Releases internal stress for high precision) |

| Diameter Of Shafts | Φ80mm Solid |

| Material Of Shafts | High Grade 45#, Heat Treated |

| Forming Speed | 15 m/min |

| Voltage | 380V / 50Hz / 3P (Customizable) |

| Transmission Way | By 1 Inch Chain (Double Chains) |

| Main Motor | 11 kW |

| Cutting Blade Material | GCr12 Quenched Treatment |

| Cutting Type | Hydraulic Post Cutting |

| Driving Method | By Pillar Type Cylinder |

Machine Matcher supplies customers worldwide with a variety of roll forming machines, including:

If you have profile drawings or additional specifications, please email them to [email protected] for an accurate quote.

Q: What is the forming speed of this machine?

A: The machine has a forming speed of 15 meters per minute, making it efficient for large-scale roofing production.

Q: What materials can be processed with this machine?

A: The machine is designed to process PPGI (Pre-Painted Galvanized Iron) and PPGL (Pre-Painted Galvalume), commonly used in roofing applications.

Q: Is the machine suitable for use in the UAE's climate?

A: Yes, the machine is designed to produce high-quality roofing tiles that withstand the hot and humid climate of the UAE, ensuring durability and longevity.

Q: What kind of maintenance is required?

A: Regular maintenance includes cleaning rollers, checking lubrication systems, inspecting the cutting blade, and ensuring the chain drive system is properly tensioned.

Q: Does the machine come with installation and training support?

A: Yes, installation and training support can be provided as per the customer's request.

Q: Can the machine be customized for different profiles?

A: Absolutely. Each machine is custom-built to meet customer-specific profile and production requirements.

For more information or to request a quote, please contact [email protected].

Copyright 2026 © Machine Matcher.