To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

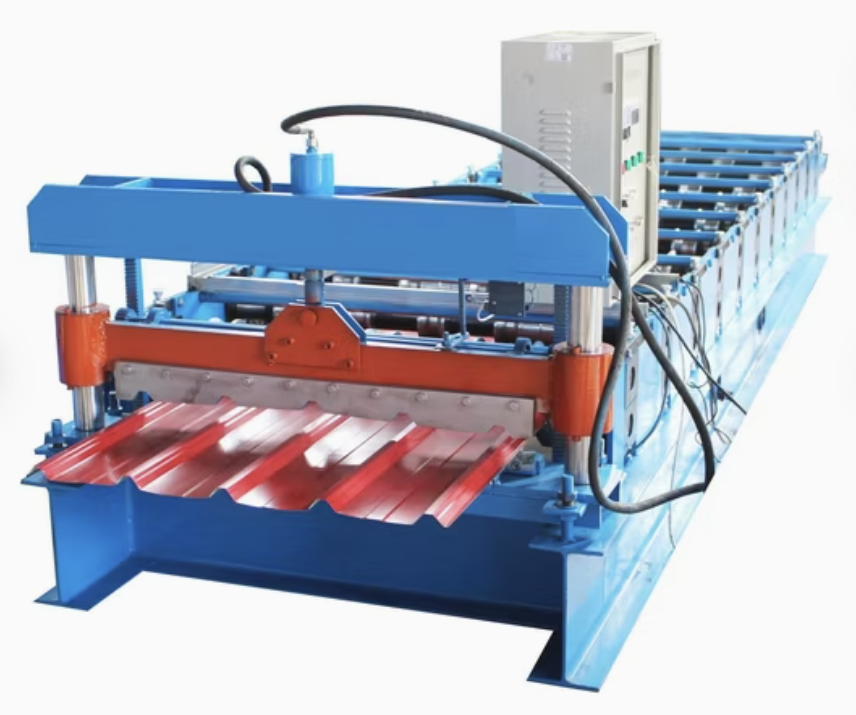

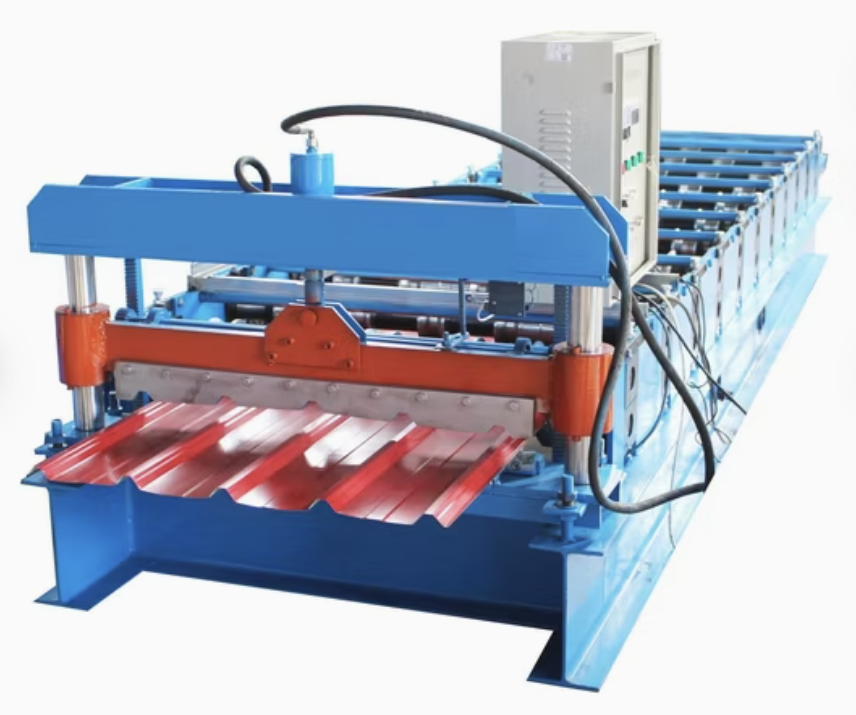

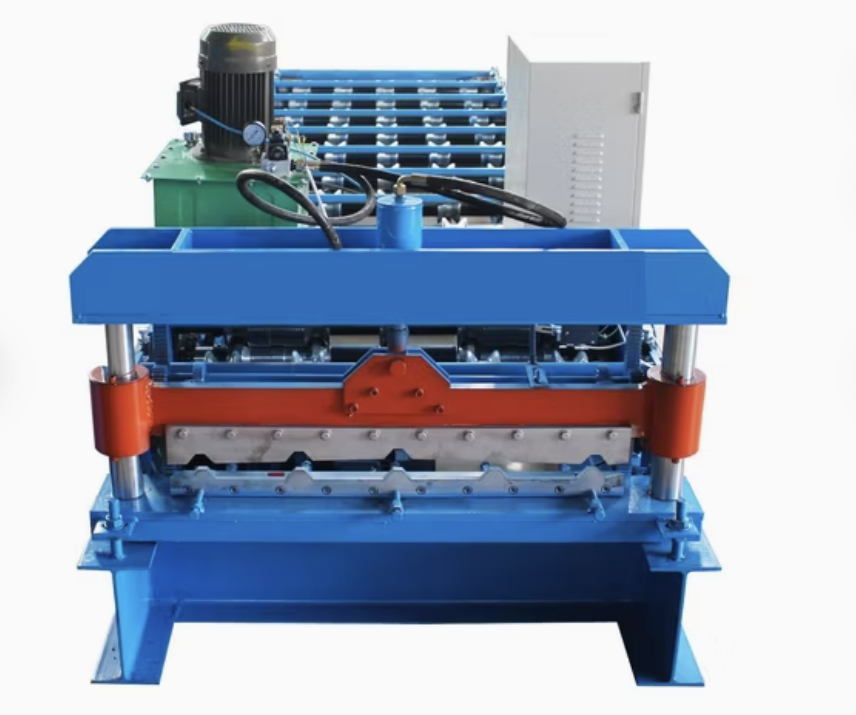

A roofing sheet roll forming machine is a specialized industrial equipment designed to produce roofing panels in various shapes and sizes. These machines are widely used in the construction and building materials industries due to their efficiency and ability to produce consistent, high-quality roofing sheets. The machine transforms metal coils into finished roofing sheets through a series of rollers that gradually form the desired profile.

Roofing sheet roll forming machines are versatile and can produce a range of profiles, including corrugated sheets, trapezoidal sheets, and standing seam panels. These sheets are used in residential, commercial, and industrial roofing applications due to their durability, weather resistance, and aesthetic appeal.

| Feature | Details |

|---|---|

| Material Thickness | 0.3 mm to 1.2 mm (varies based on the profile) |

| Material Width | 1000 mm to 1250 mm (customizable based on customer requirements) |

| Material Type | Galvanized steel, pre-painted steel, aluminum, and other metals |

| Roller Material | High-grade steel (e.g., 45# steel or GCr15) with heat treatment for durability |

| Roller Stations | 16–24 stations (depending on the profile) |

| Drive System | Chain or gear-driven system |

| Main Motor Power | 5.5 kW to 15 kW (varies based on machine size and complexity) |

| Cutting System | Hydraulic cutting with high-precision blades |

| Control System | PLC (Programmable Logic Controller) with HMI (Human-Machine Interface) |

| Machine Speed | 10–30 meters per minute (higher speeds available for advanced models) |

| Profile Options | Corrugated, trapezoidal, standing seam, tile-shaped, and custom profiles |

| Length Tolerance | ±1 mm |

| Dimensions | Varies by model (approx. 7m–12m length, 1.5m–2.5m width, 1.5m–2m height) |

| Weight | 5–12 tons (depending on machine size and features) |

| Power Supply | 220V/380V/440V, 50/60 Hz (customized for USA market standards) |

| Optional Add-ons | Decoilers (manual or automatic), stackers, remote PLC control, and coil feeders |

Q1: What profiles can a roofing sheet roll forming machine produce?

A1: A roofing sheet roll forming machine can produce profiles such as corrugated, trapezoidal, standing seam, tile-shaped, and other custom designs based on the dies and rollers installed.

Q2: What materials are compatible with these machines?

A2: Compatible materials include galvanized steel, pre-painted steel, aluminum, and other metals with thicknesses ranging from 0.3 mm to 1.2 mm.

Q3: Can the machine be customized for specific requirements?

A3: Yes, the machine can be customized for profile dimensions, material width, and additional features like automatic stackers and advanced cutting systems.

Q4: What power requirements are typical for the USA?

A4: Machines are available with power configurations of 220V/440V, 60 Hz, which align with USA industrial standards.

Q5: What is the average production speed?

A5: The production speed ranges from 10 to 30 meters per minute, with advanced models capable of higher speeds.

Q6: How is the machine maintained?

A6: Regular maintenance involves lubrication of rollers, checking the hydraulic system, cleaning, and inspecting electrical components. Preventive maintenance ensures long-term efficiency.

Q7: Are these machines easy to install and operate?

A7: Yes, the machines come with detailed installation manuals, and most models include PLC systems that simplify operation.

Q8: What additional equipment might be needed?

A8: Optional equipment includes uncoilers, leveling systems, stackers, and coil handling systems for enhanced production efficiency.

Q9: Is financing available for roll forming machines in the USA?

A9: Many suppliers offer financing options or partnerships with financial institutions to help businesses purchase roll forming machines.

Q10: What industries in the USA use roofing sheet roll forming machines?

A10: Industries include construction, real estate development, agriculture, and industrial manufacturing.

Roofing sheet roll forming machines are a valuable investment for businesses involved in construction and manufacturing. With high precision, efficiency, and adaptability, these machines cater to the diverse needs of the USA market. Whether you're looking to produce standard profiles or customize designs, these machines provide a reliable solution for your roofing production requirements.

Copyright 2026 © Machine Matcher.