To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

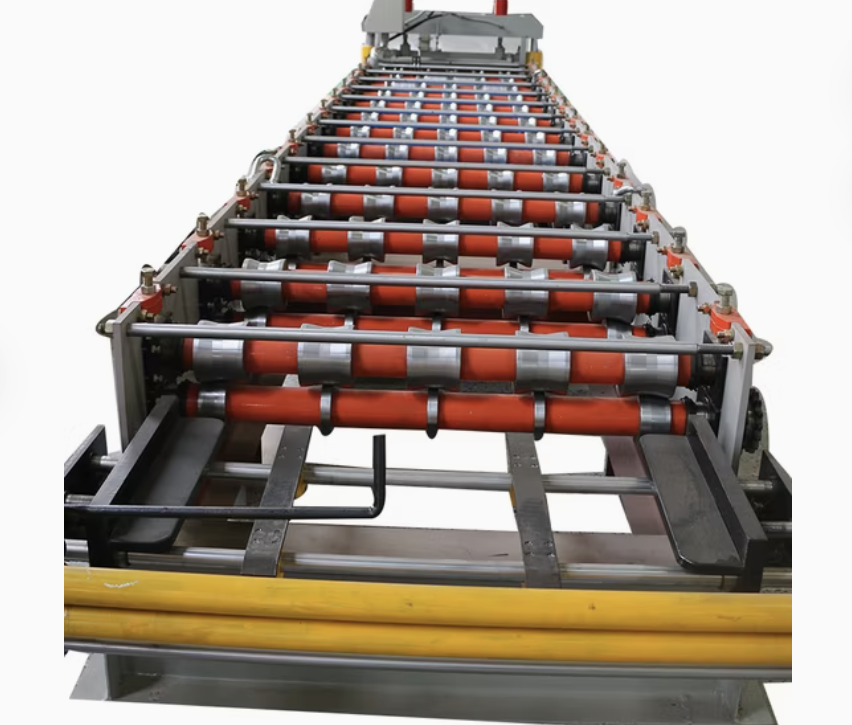

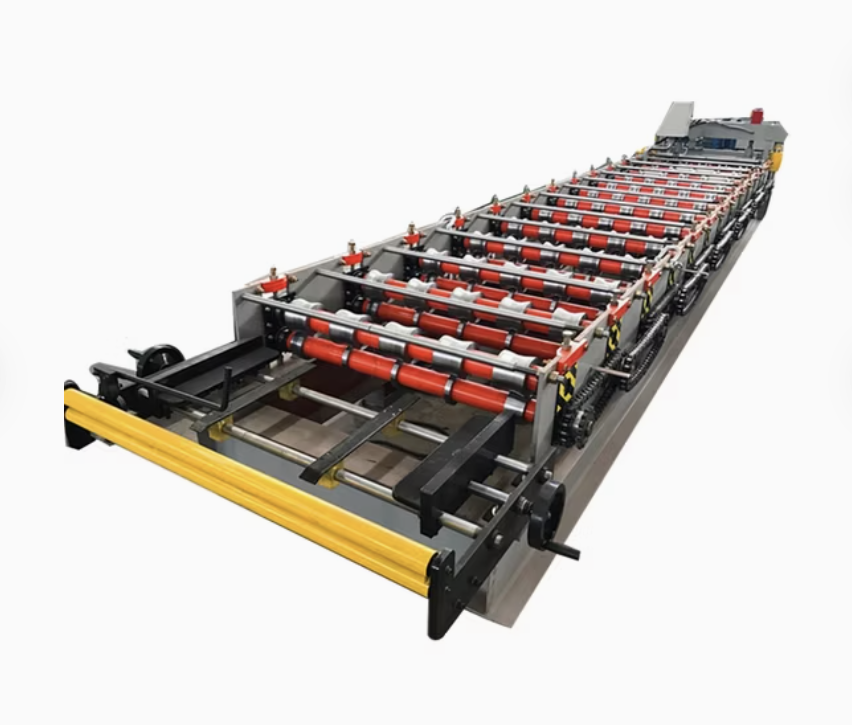

A sheet metal roll forming machine is a specialized piece of equipment used in manufacturing industries to produce precise, continuous lengths of sheet metal profiles through the process of roll forming. These machines are essential for creating a wide range of profiles used in construction, automotive, and industrial applications, such as roofing panels, siding, gutters, door frames, and more.

The roll forming process involves feeding a coil of sheet metal into the machine, where it passes through a series of rollers. Each set of rollers progressively shapes the metal until the desired profile is achieved. These machines are known for their high-speed operation, accuracy, and ability to produce complex shapes with consistent quality.

Below are the typical specifications for a sheet metal roll forming machine, tailored to meet the needs of the U.S. market:

Q1: What types of sheet metal can this machine process?

A: The machine is designed to handle various materials, including galvanized steel, aluminum, stainless steel, copper, and pre-painted steel. The material thickness can range from 0.3 mm to 1.2 mm, depending on the specific model.

Q2: Can I customize the profile design?

A: Yes, most manufacturers offer customization options. You can provide a profile drawing or sketch, and the machine will be tailored to produce your desired design.

Q3: How much space is required for installation?

A: A typical sheet metal roll forming machine requires a workspace of approximately 10–20 meters in length and 2–4 meters in width, depending on the machine size.

Q4: Is the machine suitable for high-volume production?

A: Absolutely. These machines are engineered for high-speed operation and can produce up to 30 meters of profile per minute, making them ideal for high-volume production.

Q5: What is the average lifespan of the rollers?

A: The rollers are made from hardened steel and, with proper maintenance, can last 10–15 years or longer.

Q6: How can I ensure compliance with U.S. safety standards?

A: Machines sold in the U.S. typically comply with OSHA and ANSI safety standards. Look for safety features such as emergency stops, safety guards, and noise reduction systems.

Q7: How is the machine powered?

A: Most roll forming machines in the U.S. market are designed to operate on a 3-phase, 220V/380V, 50/60 Hz power supply.

Q8: What maintenance is required?

A: Regular maintenance includes lubricating moving parts, checking roller alignment, inspecting electrical connections, and replacing worn-out components. Following the manufacturer's maintenance schedule will ensure optimal performance.

Q9: Can the machine be operated remotely?

A: Yes, many modern machines come with remote PLC systems, allowing you to control and monitor operations remotely.

Q10: What is the typical lead time for delivery in the USA?

A: Depending on customization requirements and shipping distance, the lead time ranges from 6 to 12 weeks.

A sheet metal roll forming machine is a robust and versatile solution for producing high-quality sheet metal profiles. With features like precision rollers, high-speed operation, and user-friendly controls, these machines are indispensable in industries across the USA. By understanding the specifications, capabilities, and maintenance requirements, businesses can make informed decisions when investing in this equipment.

Copyright 2026 © Machine Matcher.