To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Shutter doors are widely used in commercial, industrial, and residential applications across the USA. Their robust and versatile design makes them ideal for securing properties and providing protection against environmental factors. Shutter door roll forming machines are specialized equipment designed to manufacture shutter doors efficiently, consistently, and with high precision. These machines cater to the high demand in industries like retail, warehouses, and garages.

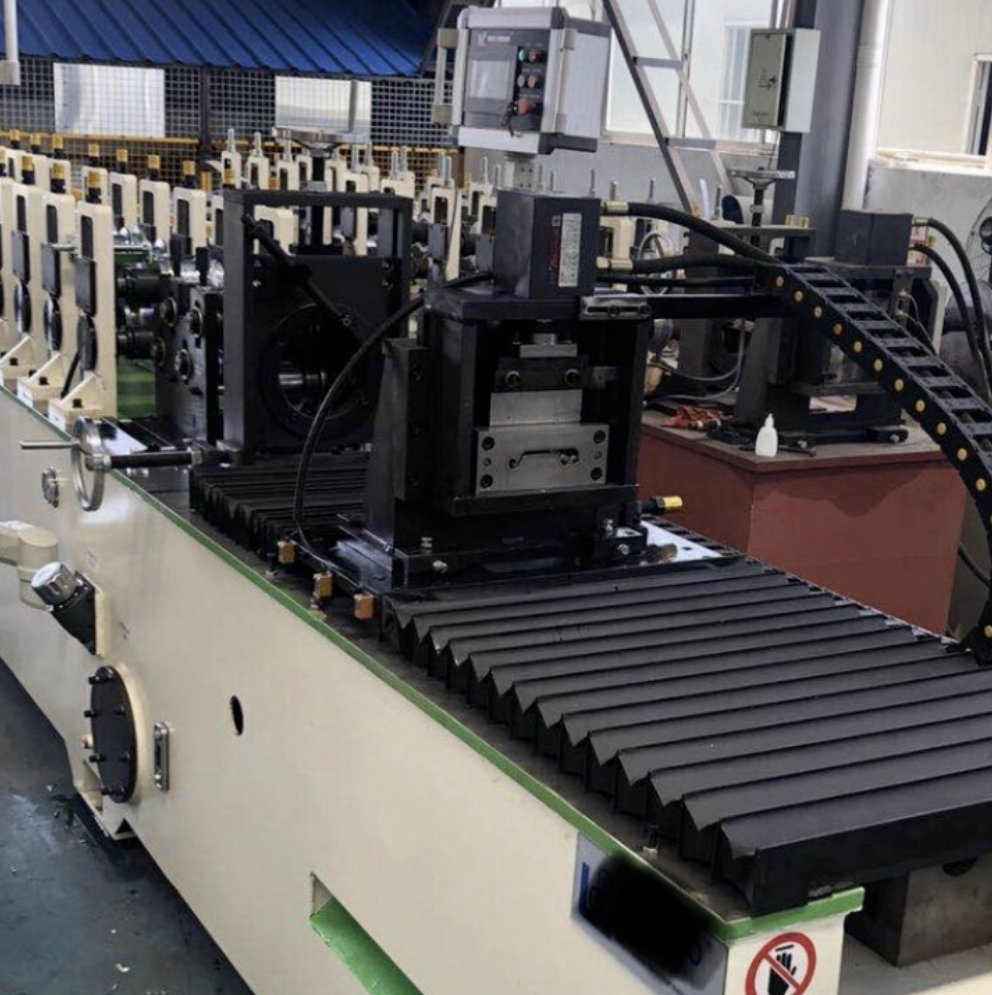

A shutter door roll forming machine is a fully automated piece of equipment designed to produce shutter door panels from metal coils. The machine processes raw materials into a finished shutter door profile through a series of rolling and forming steps. These machines are equipped with advanced control systems to ensure accuracy, efficiency, and reduced wastage.

The production capacity varies between 10–30 meters per minute, depending on the machine model and material specifications.

Yes, the machine can be configured to produce a wide range of profiles, including perforated and embossed designs.

Yes, machines can be customized to operate on 220V or 480V, 60Hz power supply, which is standard in the USA.

The machine can process galvanized steel, aluminum, and stainless steel, with thicknesses ranging from 0.5mm to 1.5mm.

Yes, training is provided during installation to ensure operators understand machine functions, maintenance, and safety protocols.

Delivery typically takes 4–8 weeks, depending on the machine model and customization requirements.

The machine comes with a 12–24 month warranty, depending on the manufacturer. Extended warranties may also be available.

Yes, the machine is equipped to manufacture both solid and perforated panels, with optional units available for specific requirements.

The price ranges from $50,000 to $150,000, depending on machine specifications, optional features, and customization.

Yes, most manufacturers ensure the availability of spare parts in the USA or can ship them quickly from their warehouses.

Shutter door roll forming machines are an essential investment for manufacturers in the USA looking to produce high-quality shutter door panels. With robust construction, customizable features, and user-friendly operation, these machines streamline the production process while maintaining superior product quality. For businesses looking to expand their operations, this equipment offers a reliable and cost-effective solution.

Copyright 2026 © Machine Matcher.