To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

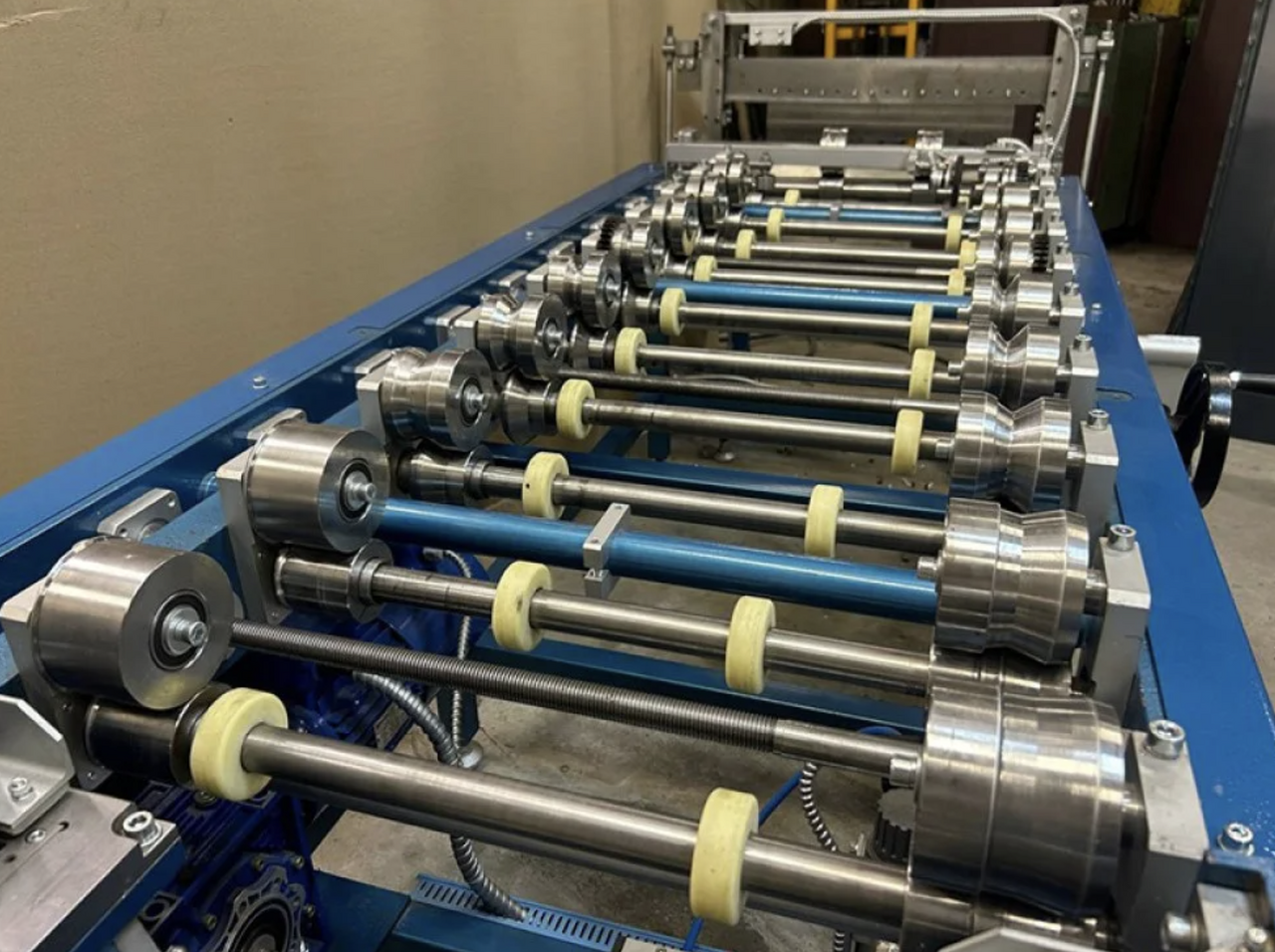

Roll form machine for snaplock standing seam panel

The Snaplock Standing Seam Panel Roll Forming Machine (SLP-1 Auto) represents the cutting edge of roofing panel production. It is specifically designed to produce click-seam panels with precision and efficiency. This machine integrates side punching capabilities and advanced automation, ensuring high-quality output while minimizing labor efforts.

The SLP-1 Auto is engineered to produce click-seam panels with fixation holes and side-part cuts. Its unique side punching mechanism allows the edges of the panels to be bent and seamlessly joined to roof elements. The fully automated system streamlines the production process, requiring minimal manual intervention.

Production Workflow:

The machine’s design ensures that side cuts are performed at the beginning of the process and the final shear only cuts flat sections of the panel. This method enhances panel quality, avoiding deformations often caused by guillotine shears cutting through profiled sections.

Q1: What makes the SLP-1 Auto unique compared to other roll forming machines?

A1: The SLP-1 Auto incorporates side punching at the start of the process, ensuring precise edge cuts and panel integrity. Its automation system also allows for seamless and efficient production.

Q2: What is the maximum thickness of the metal that can be used?

A2: The machine supports sheet metal with a thickness range of 0.6 to 0.7 mm.

Q3: Can this machine produce custom panel designs?

A3: Yes, the machine includes options for ribbed panel rolls and microwave panel modules to create customized panel profiles.

Q4: What are the power requirements for the machine?

A4: The rolling machine requires 1.5 kW and the guillotine shears require 1.1 kW. Both are compatible with 220V or 380V power supplies.

Q5: How fast is the production process?

A5: The rolling speed is up to 10 meters per minute, ensuring efficient production.

Q6: Are there any additional components to enhance the machine’s functionality?

A6: Optional components include a cutting knife, ribbed panel rolls, microwave panel modules, and various types of metal unwinders.

The Snaplock Standing Seam Panel Roll Forming Machine (SLP-1 Auto) is a revolutionary tool for metal roofing production, delivering unmatched precision, versatility, and automation for roofing contractors and manufacturers worldwide.

Copyright 2026 © Machine Matcher.