To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

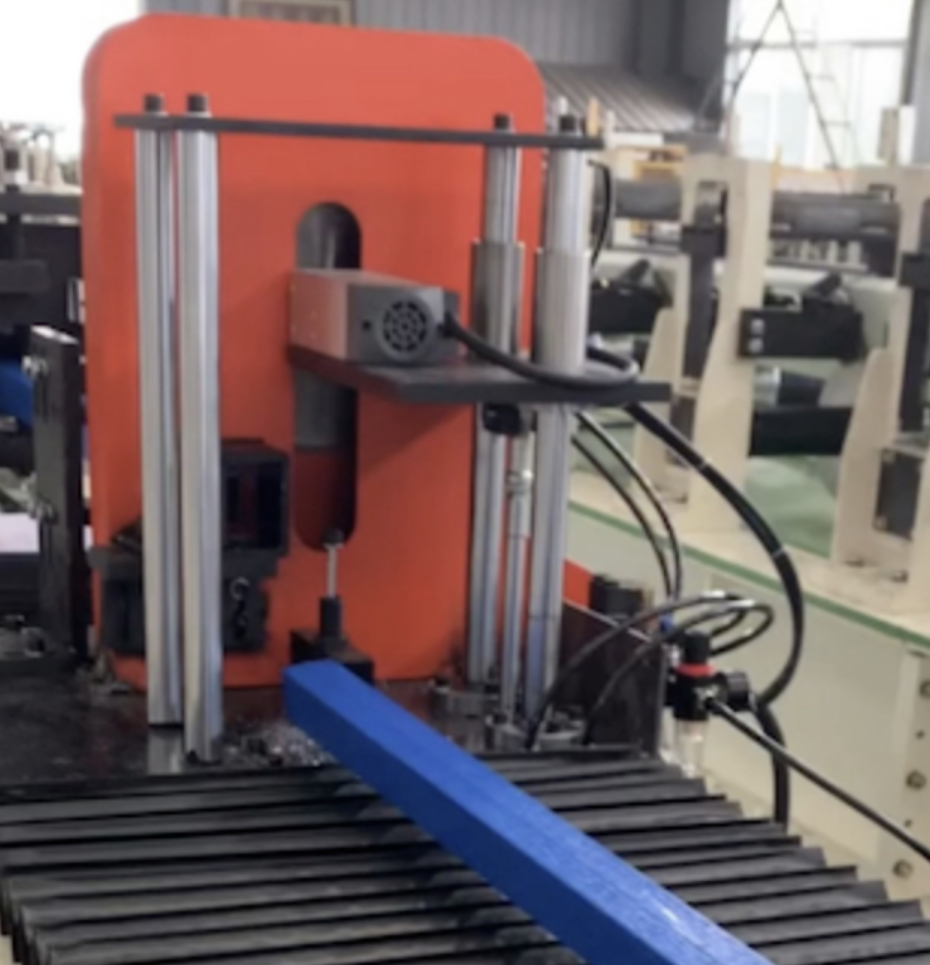

A Square Pipe Roll Forming Machine is a specialized equipment designed for the efficient production of square and rectangular hollow pipes. These pipes are widely used in industries such as construction, automotive, furniture, and mechanical applications. This machine uses a series of rollers to shape flat metal sheets into square or rectangular pipes with precision and consistency.

The Square Pipe Roll Forming Machine is engineered to handle various materials, including galvanized steel, stainless steel, aluminum, and cold-rolled steel, making it a versatile choice for manufacturers in the USA.

The Square Pipe Roll Forming Machine operates by feeding metal coils through a series of rollers, which gradually form the material into the desired pipe shape. The process is automated, ensuring high speed, accuracy, and minimal waste. These machines are equipped with advanced PLC (Programmable Logic Controller) systems for seamless operation and precise customization.

| Specification | Details |

|---|---|

| Material Thickness | 0.5 mm to 3.0 mm |

| Material Width | Up to 600 mm |

| Roller Material | High-grade chromium steel (Cr12) |

| Forming Speed | 15-20 m/min (higher speeds optional) |

| Pipe Sizes | 20x20 mm to 120x120 mm |

| Cutting System | Hydraulic or servo-driven cutting system |

| Motor Power | 7.5 kW to 15 kW |

| PLC Control System | Siemens or Mitsubishi |

| Hydraulic Power | 5.5 kW |

| Voltage Requirements | 380V/50Hz (customizable for USA standards) |

| Machine Dimensions | 10m x 1.5m x 1.5m |

| Weight | 8-10 tons |

Square and rectangular pipes are crucial in numerous industries across the USA, including:

A: The machine can handle a variety of materials, including galvanized steel, stainless steel, cold-rolled steel, and aluminum. It supports thicknesses from 0.5 mm to 3.0 mm.

A: Yes, the rollers are adjustable to accommodate various pipe sizes, ranging from 20x20 mm to 120x120 mm. Additional roller sets can be purchased for specific needs.

A: The production speed typically ranges from 15-20 meters per minute, but higher-speed options are available upon request.

A: Yes, the machine can be customized to operate at 480V/60Hz, ensuring compliance with USA standards.

A: Regular maintenance includes lubrication of rollers, inspection of electrical systems, and cleaning of hydraulic components. The machine’s PLC system provides alerts for maintenance schedules.

A: Construction, automotive, furniture, agriculture, and mechanical engineering sectors are major users of square pipes.

A: Optional features include servo motors for higher precision, an inline welding system, automatic stackers, and advanced coil handling systems like uncoilers and recoilers.

A: Yes, it can produce both square and rectangular pipes with adjustable rollers.

The Square Pipe Roll Forming Machine is an invaluable tool for manufacturers in the USA, offering precision, speed, and versatility. Its ability to handle multiple materials and customizable features makes it a preferred choice for industries requiring square and rectangular pipes. Investing in this machine ensures efficiency and quality in pipe production, meeting the high demands of the American market.

Copyright 2026 © Machine Matcher.