To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

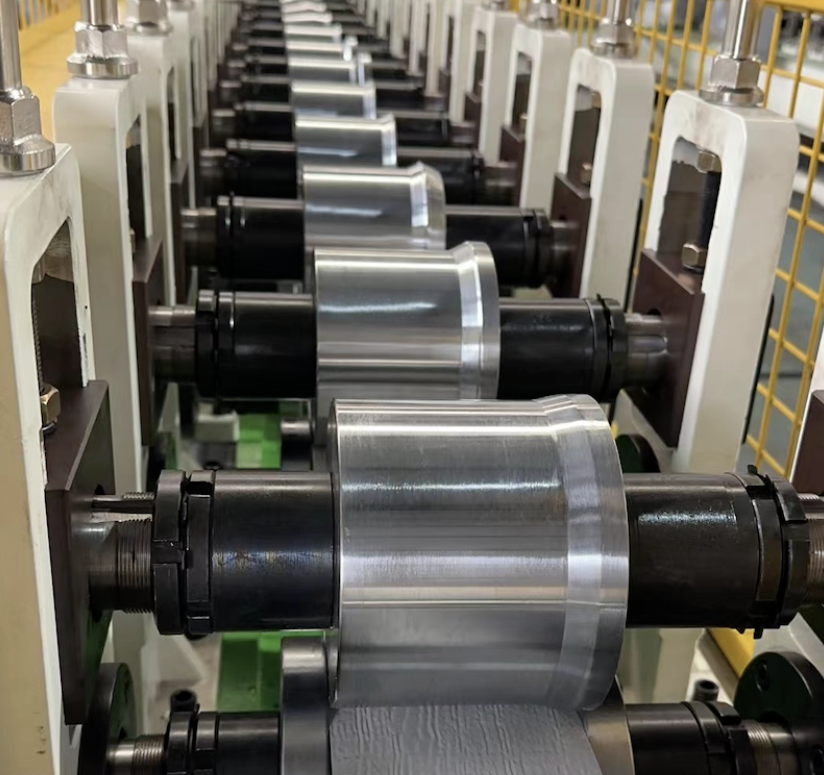

The Stainless Drip Edge Roll Forming Machine is a specialized piece of equipment designed for manufacturing drip edge profiles used in roofing systems. These profiles provide a seamless solution for guiding water away from roof edges, protecting the underlying structure from water damage. Constructed with stainless steel materials, the drip edge profiles offer superior corrosion resistance and durability, making them a top choice for both residential and commercial roofing projects.

This roll forming machine is engineered with precision and high efficiency, capable of producing consistent drip edge profiles with a clean finish. With advanced automation and controls, the machine minimizes manual intervention while ensuring consistent quality and productivity.

Q1: What is a drip edge, and why is stainless steel preferred?

A1: A drip edge is a metal flashing installed along roof edges to direct water away from the structure, preventing water damage and erosion. Stainless steel is preferred because it is highly resistant to rust, corrosion, and extreme weather, ensuring longevity and minimal maintenance.

Q2: Can this machine handle other materials besides stainless steel?

A2: Yes, the machine can also process galvanized steel and aluminum. However, stainless steel is recommended for applications requiring superior durability and resistance.

Q3: What is the average production capacity of this machine?

A3: The production capacity ranges from 15 to 30 meters per minute, depending on the material and profile design.

Q4: Is the machine suitable for U.S. power requirements?

A4: Yes, the machine can be configured to meet U.S. power standards (e.g., 380V, 60Hz).

Q5: How customizable is the profile size?

A5: The machine is highly customizable, allowing adjustments to profile width, height, and thickness to meet specific customer needs.

Q6: What kind of maintenance does this machine require?

A6: Regular maintenance includes lubrication of moving parts, checking the hydraulic and electrical systems, and cleaning the rollers to ensure consistent performance.

Q7: Does the machine come with a warranty?

A7: Most manufacturers offer a one-year warranty covering parts and labor. Additional warranties may be available upon request.

Q8: Are installation and training included?

A8: Yes, installation and operator training are typically provided, either on-site or remotely, depending on customer preference.

This machine is an ideal investment for roofing companies and contractors looking to expand their production capabilities in the U.S. market, offering durability, precision, and efficiency.

Copyright 2026 © Machine Matcher.