To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

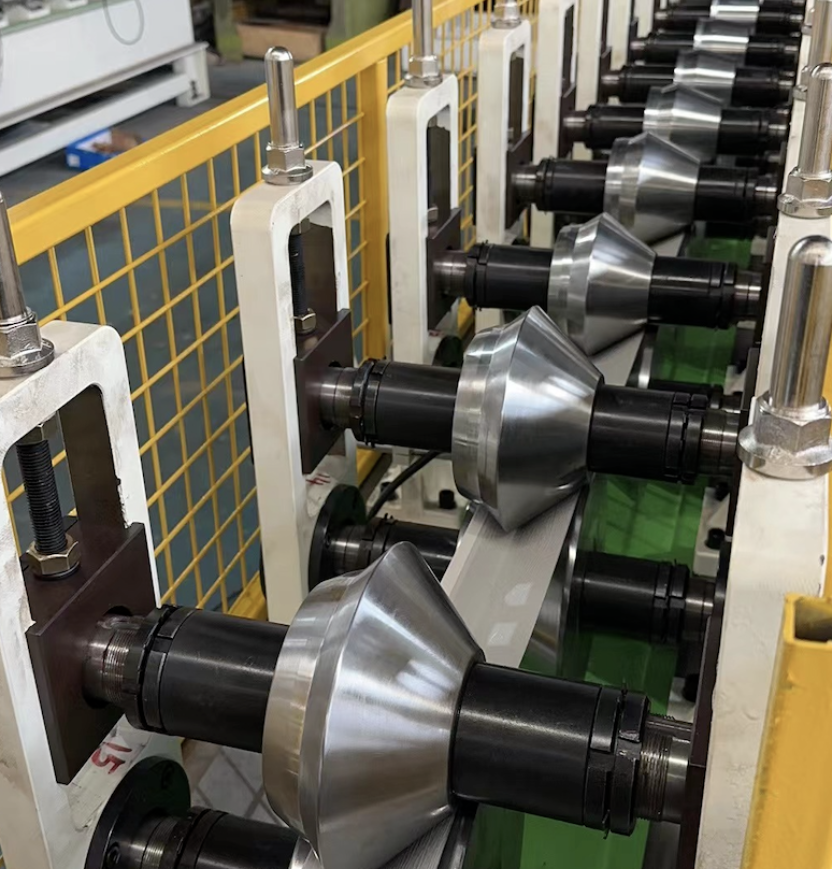

The Standard Drip Edge Flashing Roll Forming Machine is a state-of-the-art solution designed to produce high-quality drip edge flashings efficiently and precisely. Built to operate seamlessly in the challenging climates of Alaska, this machine is ideal for manufacturers, contractors, and roofing specialists who demand reliability and customization.

Custom-built to meet specific profile and machine requirements, each machine is shipped directly from our manufacturing partner to your location in Alaska. Backed by a one-year warranty from dispatch, we also offer comprehensive maintenance, repair support, and setup services to ensure smooth and uninterrupted production.

Whether you need standard or custom drip edge profiles, this machine can handle a wide range of options to fit residential, commercial, and metal roofing systems. Pricing is customized based on optional extras and specific requirements—contact us for a personalized quote.

This machine is perfect for industries involved in:

Pricing is determined based on optional extras and customization requirements. For a tailored quote, please contact us at [email protected] with your profile drawings or specifications.

The machine can produce drip edges at a speed of 80 feet per minute, ensuring high efficiency for both residential and commercial projects.

Yes, the machine is custom-built to handle both standard and custom profiles. Please share your profile drawings for a tailored quote.

It can form drip edges from aluminum, galvanized steel, and copper, covering a wide range of roofing requirements.

Absolutely. The machine's design and material compatibility ensure it can operate efficiently in the harsh climates of Alaska.

It requires an electric power supply of 240V, three-phase, 60 Hz.

The machine comes with a one-year warranty from dispatch, covering maintenance and repair. We also offer comprehensive support for setup, adjustment, and ongoing maintenance.

Yes, please send your profile drawings and specifications to [email protected] for a precise and customized quote.

The machine supports face sizes ranging from 1 1/2-inch (F5) to 4-inch (F10), making it versatile for both residential and commercial applications.

Shipping times may vary based on customization requirements. For an accurate estimate, please contact us directly.

For more information or to request a quote, email us at [email protected].

Copyright 2026 © Machine Matcher.