To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

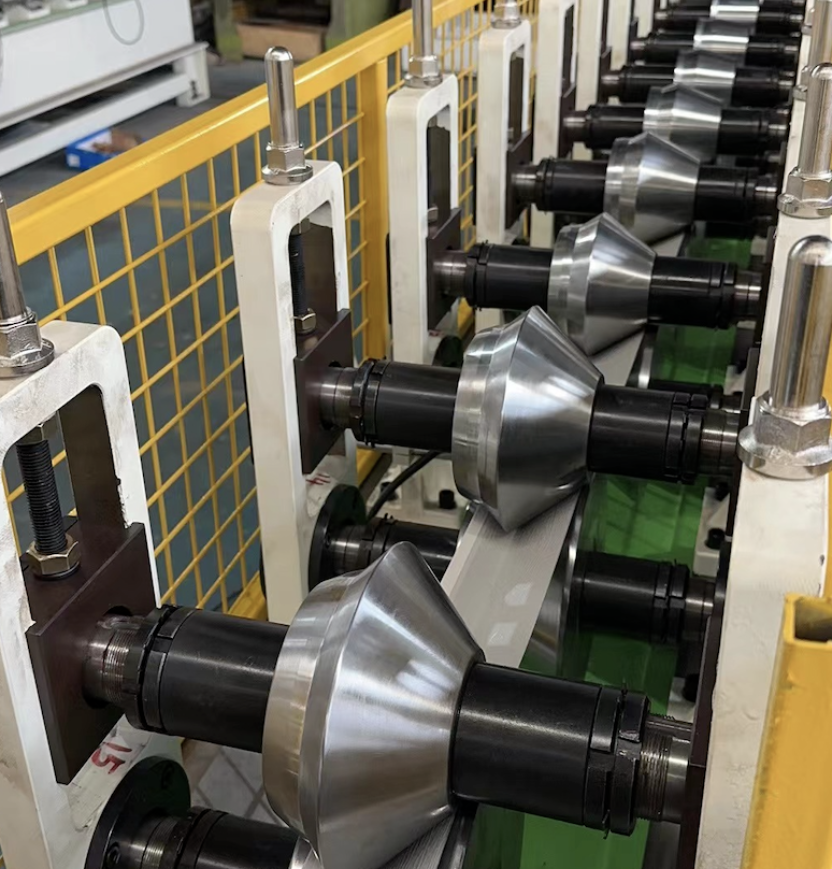

The Standard Drip Edge Flashing Roll Forming Machine is designed to manufacture high-quality drip edge profiles for both residential and commercial roofing applications in Arkansas, USA. This custom-built machine offers precision and efficiency, catering to the specific profile and size requirements of customers.

Engineered to handle a range of materials including aluminum, galvanized steel, and copper, this machine ensures durability and a smooth production process. With a high-speed capacity of 80 feet per minute and an electric shear for clean cuts, it is an ideal solution for contractors and manufacturers in the roofing industry.

Machine Matcher offers worldwide shipping directly from our manufacturing partners, ensuring timely and secure delivery. The machine comes with a one-year warranty from dispatch and comprehensive maintenance and repair support.

The Standard Drip Edge Flashing Roll Forming Machine is widely used in the roofing and construction industries, particularly for:

To get a tailored quote or more information, please email your profile drawings and requirements to [email protected].

A: Yes, the Standard Drip Edge Flashing Roll Forming Machine can be customized to produce a variety of profiles, including C5, C6, F4, 90 Degree, D Style, FHA, and other custom profiles.

A: The machine supports aluminum, galvanized steel, and copper, with thicknesses ranging from 0.019 inch to 0.032 inch.

A: Yes, Machine Matcher provides full installation support, including setup and adjustments to ensure optimal performance.

A: Pricing is based on the optional extras and customization requirements. For a specific quote, please contact us with your detailed requirements.

A: Delivery times vary based on customization and shipping logistics. Typically, orders are processed and shipped within 4-8 weeks.

A: Yes, it includes a one-year warranty from the date of dispatch, covering parts and service.

A: Yes, spare parts and optional accessories are available upon request.

For more information or to place an order, contact us at [email protected] or visit our website.

Copyright 2026 © Machine Matcher.