To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

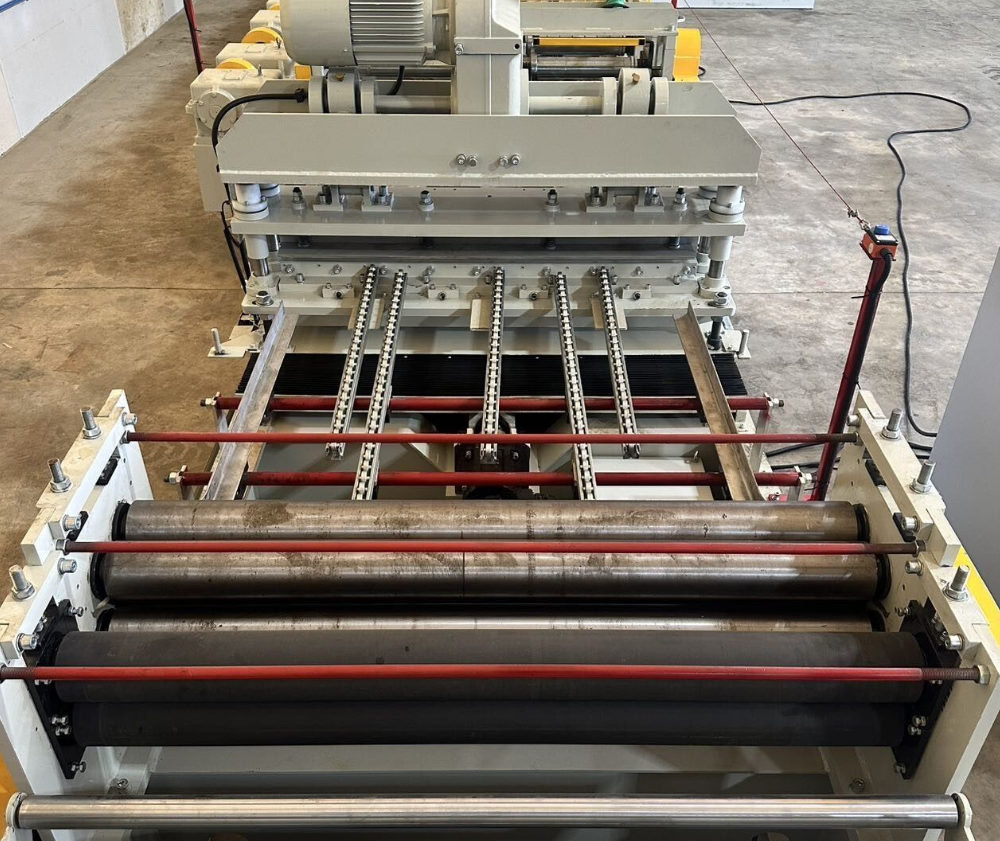

The Steel Composite Deck Roll Forming Machine is a high-performance solution designed for the construction and building industries in Arizona, USA. This machine is engineered to produce a range of steel composite deck profiles, including 1.5-inch B deck, 3-inch N deck, composite metal deck, and steel form deck. Built with precision and durability, it meets the demands of large-scale commercial and industrial projects, providing superior strength and load-bearing capabilities.

All our machines are custom-built to meet specific profile and machine requirements, ensuring that every client gets a solution tailored to their project needs. This machine will be shipped directly to your location from our manufacturing partner, ensuring fast and reliable delivery. Pricing is determined based on optional extras and customization requirements. Contact us for a tailored quote based on your specific needs.

The Steel Composite Deck Roll Forming Machine is ideal for the following industries:

1. What is the lead time for delivery in Arizona?

Delivery times depend on customization requirements but typically range from 8 to 12 weeks from the date of order confirmation.

2. Can the machine handle custom profiles?

Yes, we can design and build machines for custom profiles based on your requirements.

3. What type of maintenance support is available?

We offer comprehensive maintenance and repair services, including setup and adjustment for all our roll forming machines.

4. Are safety features included in the machine?

Yes, the machine comes with optional safety covers and emergency stops to ensure operator safety.

5. How is pricing determined for the machine?

Pricing is based on the selected customization options, optional extras, and specific profile requirements. Contact us for a tailored quote.

6. Can this machine handle different material gauges?

Yes, it is designed to process material thickness ranging from 18 gauge to 22 gauge, ensuring versatility for various applications.

7. Is training provided for machine operation?

Yes, we offer setup and training services to ensure your team can operate the machine efficiently.

For more information or to get a quote, please contact us at [email protected].

Copyright 2026 © Machine Matcher.