To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

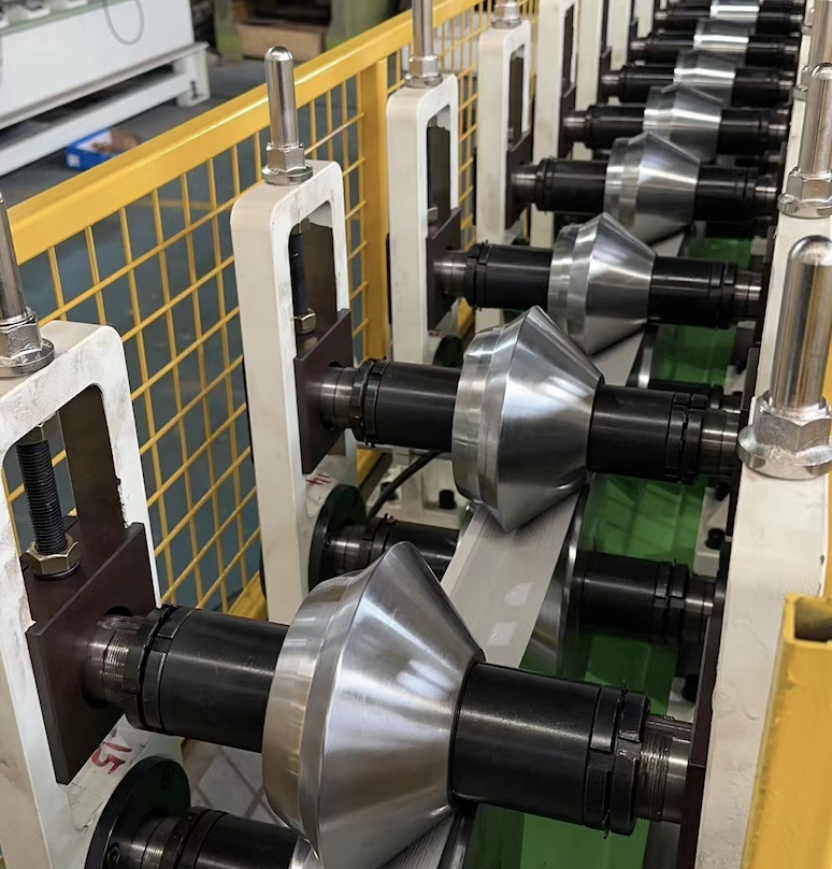

The Steel Drip Edge Roll Forming Machine is a high-performance, custom-built solution designed to meet the unique demands of the roofing and construction industries in Alaska, USA. Engineered to produce precise and durable drip edge profiles, this machine ensures superior protection against water infiltration, safeguarding roof edges from harsh Alaskan weather conditions, including snow, rain, and ice.

All machines are new and custom-built to match the customer’s specific profile and machine requirements, ensuring a seamless fit for both residential and commercial applications. Once manufactured, the machine is shipped directly from our trusted manufacturing partner to the customer's location in Alaska.

Pricing for the Steel Drip Edge Roll Forming Machine is determined based on optional extras and customization requirements. Contact us for a tailored quote that aligns with your specific needs. Each machine is covered by a comprehensive one-year warranty from the dispatch date, complemented by durable maintenance and repair support.

Machine Matcher is dedicated to serving customers worldwide, providing a full range of machine sales, maintenance, repair, setup, and adjustment services for the roll forming industry. Our product portfolio includes metal roof panel machines, metal flashing machines, purlin machines, metal trim machines, slitting lines, metal tile machines, uncoilers, coil cars, embossers, and more.

For a detailed and accurate quote, customers can email their profile drawings or any other relevant information to [email protected].

This roll forming machine can produce a wide range of drip edge profiles, including both standard and custom options:

This Steel Drip Edge Roll Forming Machine is widely used in:

A: Yes, the Steel Drip Edge Roll Forming Machine is fully customizable to produce a wide range of standard and custom profiles based on your requirements.

A: Absolutely. The machine operates on a 240V, three-phase, 60 Hz power supply, which is standard in Alaska.

A: The machine offers a high-speed production capability of 80 feet per minute, ensuring efficient output for large projects.

A: Yes, please send your profile drawings and specific requirements to [email protected] for a tailored quote.

A: It can process aluminum, galvanized steel, and copper with material thicknesses ranging from 0.019 to 0.032 inches.

A: The machine comes with a one-year warranty covering parts and manufacturing defects from the dispatch date.

A: Delivery times depend on customization requirements. Contact us for a more accurate estimate based on your order.

For more information or to get a customized quote, contact Machine Matcher today at:

Email: [email protected]

Website: Machine Matcher

Maximize your roofing project’s efficiency and durability with the Steel Drip Edge Roll Forming Machine—designed to meet the demanding standards of Alaska’s construction industry!

Copyright 2026 © Machine Matcher.