To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

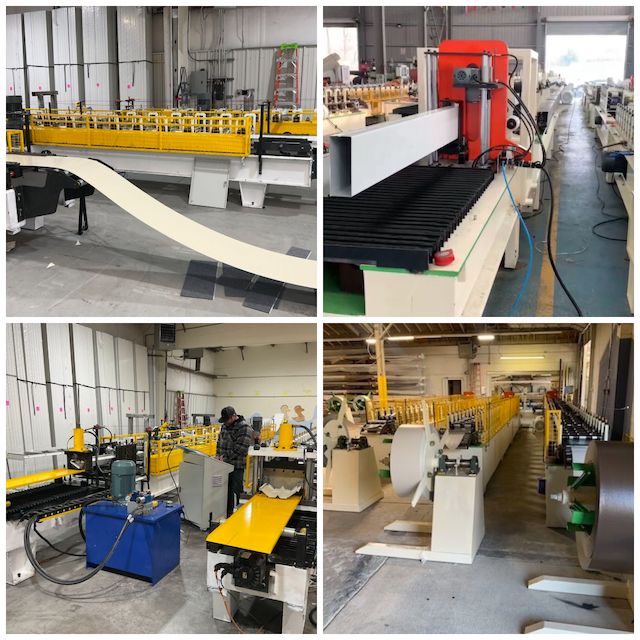

The Steel Pergola Bracing Purlin Roll Forming Machine is a precision-engineered solution tailored for the production of high-quality bracing and purlins used in pergola structures. Designed to meet the specific demands of the U.S. market, this machine ensures efficient manufacturing while adhering to American safety and power standards. With its robust design and advanced control systems, it is ideal for businesses involved in the construction and structural support industries.

This machine is built with durability and reliability in mind, using high-grade materials to ensure long-term performance. The inclusion of safety covers and emergency stops aligns with U.S. safety standards, ensuring operator safety.

The Steel Pergola Bracing Purlin Roll Forming Machine is designed to manufacture a variety of bracing and purlin profiles used in pergolas. These profiles are typically produced with the following specifications:

The machine ensures consistent output quality, producing precise and uniform profiles suitable for both residential and commercial projects.

Q1: What materials can this machine process?

A: This machine is designed to process galvanized steel, cold-rolled steel, and aluminum with a material thickness range of 0.5mm to 2.5mm.

Q2: What is the power requirement for the machine in the U.S.?

A: The machine operates on 240V, 3-phase, 60Hz, which is the standard power supply in the U.S.

Q3: How many profiles can this machine produce?

A: The machine can produce various purlin and bracing profiles, with profile widths ranging from 2 inches to 8 inches.

Q4: What safety features are included?

A: The machine is equipped with safety covers to prevent accidents and multiple emergency stops (E-Stops) for quick shutdown during emergencies.

Q5: How fast can the machine operate?

A: The forming speed is between 70 and 80 feet per minute, ensuring efficient production.

Q6: Is operator training required?

A: Basic training is recommended for understanding the Delta PLC system and safety procedures.

This machine is a reliable and efficient solution for manufacturers looking to produce high-quality steel pergola bracing and purlin profiles in the U.S. market. Its advanced features, compliance with U.S. standards, and safety measures make it a valuable addition to any roll forming production line.

Copyright 2026 © Machine Matcher.