To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

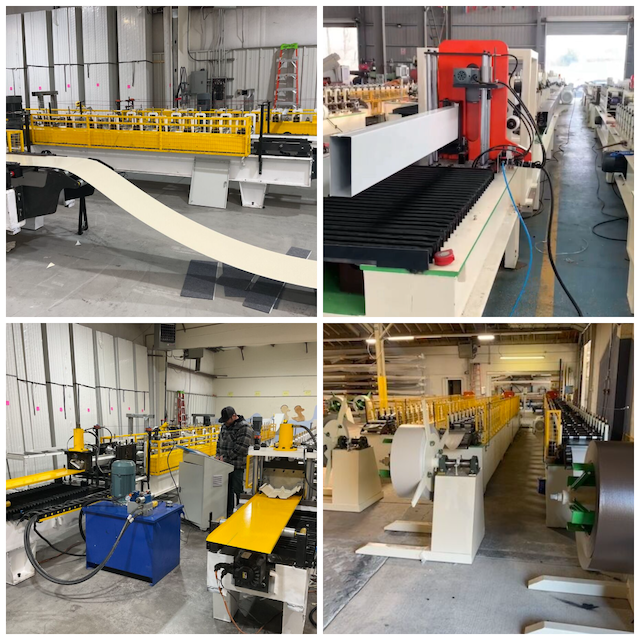

The Steel Pergola Framing Support Post Roll Forming Machine is a robust, high-speed manufacturing system designed to produce precision steel profiles for pergola support posts. Tailored for the USA market, this machine offers seamless integration into the local power supply and production requirements, making it an ideal choice for manufacturers seeking efficiency, reliability, and high-quality outputs. This machine is especially suited for fabricators serving the residential and commercial outdoor construction markets.

This roll forming machine is engineered to produce steel pergola framing support posts with precise specifications. These profiles are:

Q1. Can the machine handle different steel gauges?

A: Yes, the machine can process steel with thicknesses ranging from 18 to 12 gauge, providing flexibility for different structural requirements.

Q2. Is the machine compatible with U.S. power standards?

A: Absolutely. The machine is designed for 240V, 3-phase, 60Hz power, which is standard in the USA.

Q3. How long does installation take?

A: Installation typically takes 3-5 days, depending on the complexity of the setup and the availability of factory utilities.

Q4. What materials can be used for profiles?

A: The machine is compatible with galvanized steel, powder-coated steel, and other high-strength materials suitable for outdoor construction.

Q5. Are there any optional upgrades available?

A: Yes, optional extras include a remote PLC system for offsite monitoring, automatic stackers, and coil car tippers for enhanced efficiency.

Q6. What is the warranty period?

A: The machine comes with a standard 1-year warranty, covering manufacturing defects and parts replacement.

Q7. Can the machine produce custom profile designs?

A: Yes, the machine can be configured to produce custom profiles based on the customer’s specifications.

This Steel Pergola Framing Support Post Roll Forming Machine is a highly efficient and reliable option for businesses in the USA, offering top-notch performance and flexibility. It is a perfect investment for manufacturers aiming to scale their production of high-quality outdoor framing solutions.

Copyright 2026 © Machine Matcher.