To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Steel pergola tube roll forming machines are a crucial asset for manufacturers and fabricators who want to produce high-quality steel tubes for pergolas and similar structures. These machines are designed for efficiency, precision, and durability, making them ideal for the competitive market in the United States.

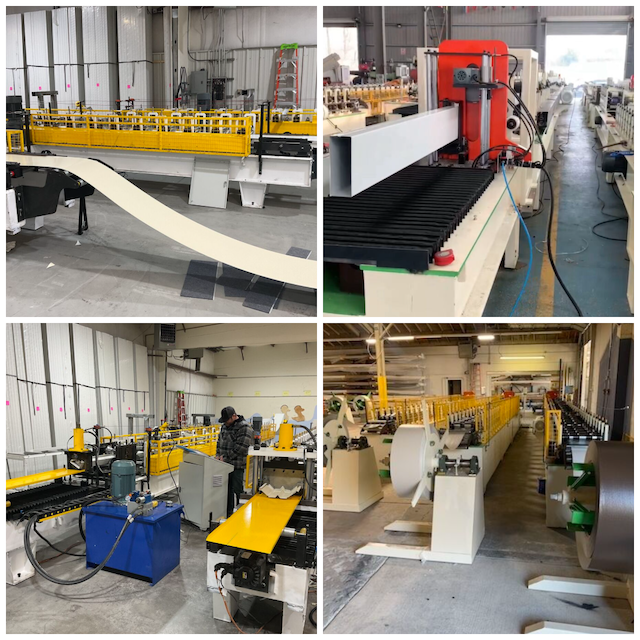

A Steel Pergola Tube Roll Forming Machine is an industrial-grade system engineered to form steel tubes of varying sizes and specifications. The machine processes steel coils into finished tubular profiles used in pergola construction, which are widely adopted in residential, commercial, and outdoor settings.

The machine is optimized for the U.S. market with its compatibility with 240V, 3-phase, 60Hz power supplies, ensuring seamless integration into local manufacturing facilities. Its design incorporates a chain drive gearbox system and a Delta control system to ensure high performance and reliability.

| Feature | Details |

|---|---|

| Forming Speed | 70 - 80 feet per minute |

| Machine Weight | 6 tons |

| Machine Footprint | 33 ft x 4 ft |

| Main Power | 240V - 3 phase - 60Hz |

| Motor | 8 HP |

| Gearbox | Chain Drive |

| Number of Stations | 22 |

| Control System | Delta |

| Safety Features | Safety Covers, Emergency Stops |

The Steel Pergola Tube Roll Forming Machine produces tubular steel profiles designed for structural integrity and aesthetic appeal in pergola construction. These profiles can be customized to meet specific project requirements.

Q: What is the primary use of a steel pergola tube roll forming machine?

A: The machine is primarily used to produce high-quality steel tubes for pergolas, which are used in residential, commercial, and outdoor spaces for shade and decorative purposes.

Q: Can the machine handle different materials?

A: Yes, the machine is compatible with galvanized steel, stainless steel, and aluminum-coated steel.

Q: Is the machine energy efficient?

A: Yes, with its 8 HP motor and chain drive system, the machine is designed to deliver optimal performance with efficient energy usage.

Q: Does the machine comply with U.S. safety standards?

A: Absolutely, the machine is equipped with safety covers and emergency stop buttons to ensure operator safety and compliance with industrial standards.

Q: Can the profiles be customized?

A: Yes, the machine allows customization of tube dimensions and material gauge to suit different project requirements.

Q: What is the forming speed of the machine?

A: The forming speed ranges between 70 and 80 feet per minute, making it highly efficient for large-scale production.

This machine is ideal for manufacturers in the U.S. looking to produce high-quality steel tubes efficiently while maintaining compliance with local standards and power requirements. The versatility and durability of the machine make it a valuable investment for businesses catering to the growing demand for pergolas and architectural steel structures.

Copyright 2026 © Machine Matcher.