To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

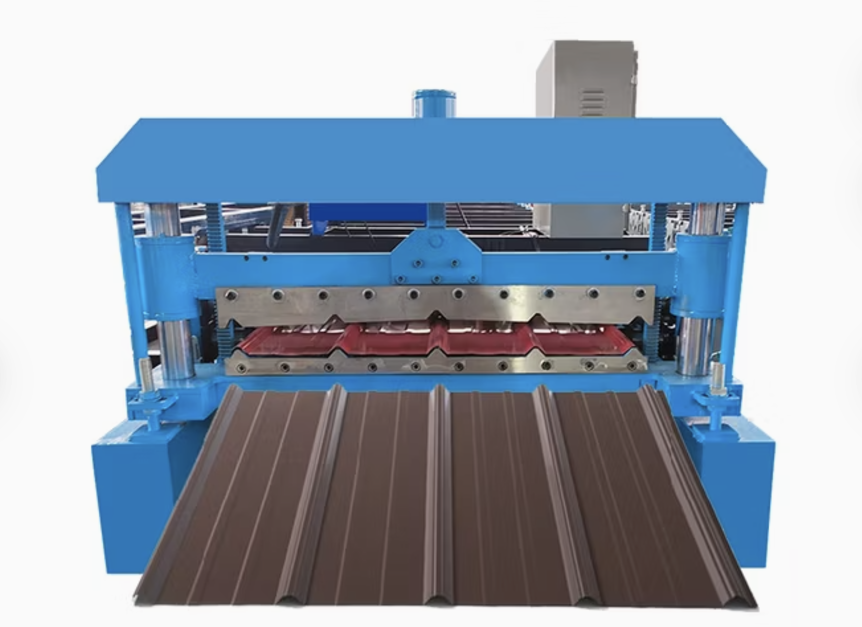

Steel roof roll forming machines are specialized equipment used to manufacture roofing sheets from metal coils. These machines are designed for precision and efficiency, ensuring consistent output of roofing profiles. In the USA, steel roof roll forming machines cater to various industries, including residential, commercial, and industrial construction. The machines are customizable to produce specific roofing profiles such as standing seam panels, corrugated sheets, and trapezoidal panels, which are popular in the American market.

These machines are known for their robust construction, high-speed operation, and capability to work with various metal types, including galvanized steel, aluminum, and pre-painted steel.

Q1: What types of roofing profiles are most popular in the USA?

A1: Standing seam panels, corrugated sheets, and PBR panels are among the most popular roofing profiles in the USA due to their durability, aesthetic appeal, and suitability for various climates.

Q2: Can the machine handle custom profile designs?

A2: Yes, many steel roof roll forming machines can be customized to produce unique profiles based on customer requirements.

Q3: What is the lead time for installation and setup?

A3: Installation and setup typically take 1–2 weeks, depending on the complexity of the machine and site preparation.

Q4: What power supply is required for these machines in the USA?

A4: Most machines are compatible with 220V/60Hz or 480V/60Hz, standard for industrial power in the USA.

Q5: How do I maintain a steel roof roll forming machine?

A5: Regular maintenance involves:

Q6: What are the shipping options for these machines in the USA?

A6: Machines can be shipped via truck freight for domestic transport or container shipping for international imports.

Q7: Are there financing options available?

A7: Many manufacturers and distributors in the USA offer financing plans or lease options to help businesses invest in these machines.

Q8: What is the price range of a steel roof roll forming machine?

A8: Prices range from $50,000 to $200,000, depending on the machine’s specifications, speed, and additional features.

Copyright 2026 © Machine Matcher.