To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

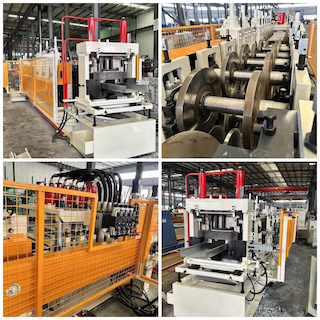

The Steel Truss Purlin Roll Forming Machine is an advanced metalworking solution designed for producing truss and purlin profiles for the construction and industrial sectors in the USA. With its high speed, precision, and robust design, this machine is optimized to meet the growing demand for customized structural profiles in roofing, wall framing, and truss systems.

The machine operates efficiently under the rigorous power requirements prevalent in the USA, utilizing a 32Hp, 480v, 3-phase main power supply, ensuring seamless and reliable performance.

| Specification | Details |

|---|---|

| Profile Size | 5" to 12" |

| Coil Width | Variable |

| Forming Speed | 50–60 ft/min |

| Material Thickness | Variable |

| Machine Weight | 15 tons |

| Machine Footprint | 60ft x 12ft |

| Main Power | 32Hp - 480V - 3ph |

| Stations | 21 |

| Cutting Type | Hydraulic shear |

| Control System | Delta |

| Safety Covers | Yes |

This machine is ideal for:

Q1: What types of materials can the machine handle?

The machine can process a variety of steel materials with variable thicknesses, depending on the structural requirements.

Q2: Is the machine suitable for high-volume production?

Yes, with a forming speed of 50–60 feet per minute, the machine is designed for high-output manufacturing.

Q3: What is the power requirement for the machine in the USA?

The machine operates on 32Hp, 480V, 3-phase power, meeting the standard industrial power configurations in the USA.

Q4: How many stations does the machine have?

The machine is equipped with 21 forming stations for precise shaping and profiling.

Q5: What kind of cutting system is included?

The machine uses a hydraulic shear cutting system for clean and accurate cuts.

Q6: Are safety features included in the design?

Yes, the machine comes with safety covers to protect operators and reduce risks during operation.

Q7: What is the typical machine weight and footprint?

The machine weighs approximately 15 tons and has a footprint of 60ft x 12ft, suitable for most industrial facilities in the USA.

Copyright 2026 © Machine Matcher.