To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Structural Purlin roll forming machines are essential for manufacturing purlins used in building construction. These purlins provide structural support for roofs and walls, making them a critical component in residential, commercial, and industrial buildings. This guide provides an in-depth overview of Structural Purlin roll forming machines tailored for the Ohio, USA market, including specifications, description, and a Q&A section.

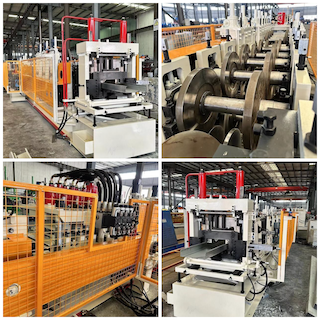

The Structural Purlin roll forming machine is designed for high efficiency, precision, and adaptability. This state-of-the-art machine caters to diverse applications, allowing for the production of purlins of varying sizes and profiles. Built with robust materials, it guarantees durability and consistent output, making it an excellent choice for manufacturers in Ohio.

This machine is specifically engineered to meet the demands of the Ohio construction industry, which requires high-quality structural components for a variety of projects, including warehouses, factories, and commercial buildings.

The Structural Purlin roll forming machine supports a wide range of purlin profiles, making it versatile for various construction applications. The machine can manufacture:

Q1: What is the production capacity of the machine?

A: The machine can produce 50-60 feet of purlins per minute, depending on the material thickness and profile.

Q2: What profiles can this machine create?

A: The machine supports the production of C-purlins, Z-purlins, U-channels, and hat channels with widths ranging from 5" to 12".

Q3: Is this machine suitable for Ohio’s climate?

A: Yes, the machine is designed to function in various environments and is built with robust materials to withstand Ohio's varying weather conditions.

Q4: What type of cutting system does the machine use?

A: It features a hydraulic shear system for precise and efficient cuts.

Q5: Can this machine handle galvanized steel?

A: Absolutely, the machine is equipped to handle galvanized steel and other materials suitable for structural purlins.

Q6: How much space is required to set up the machine?

A: The machine requires a footprint of 60 ft x 12 ft, making it suitable for medium to large manufacturing facilities.

Q7: Does the machine comply with safety standards?

A: Yes, the machine includes safety covers and adheres to international safety standards for operator protection.

Ohio has a strong construction and manufacturing sector that demands high-quality structural components. This machine’s ability to produce precise, customizable purlins at a high speed ensures it meets local industry standards and project requirements efficiently. Its adaptability and robust construction make it an invaluable asset for manufacturers looking to scale operations in Ohio.

Copyright 2026 © Machine Matcher.