To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

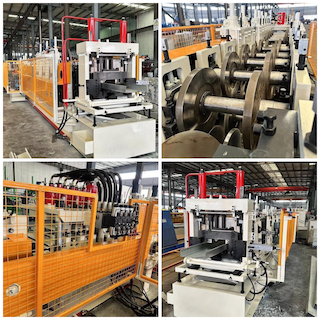

The Structural Purlin Roll Forming Machine is a versatile and robust equipment designed for manufacturing structural purlins used in construction and industrial applications. In Texas, where construction and industrial projects are constantly evolving, this machine is crucial for producing high-quality purlins that meet the specific demands of the local market. Whether for large-scale commercial projects, industrial facilities, or agricultural buildings, this machine offers efficiency, precision, and reliability.

The Structural Purlin Roll Forming Machine is engineered to produce purlins in a range of profiles and sizes. Its advanced features, including a hydraulic shear cutting system and a Delta control system, ensure seamless operation and consistent output. With a heavy-duty frame and cutting-edge technology, this machine is ideal for the production of variable-width profiles and varying material thicknesses.

This machine is particularly suited for the Texas market, where high-volume production, durability, and adaptability are essential due to the state’s thriving construction industry. The machine's efficiency in forming structural purlins aligns with the region's demand for high-quality, load-bearing components in construction projects.

| Feature | Specification |

|---|---|

| Profile | 5" to 12" |

| Coil Width | Variable |

| Forming Speed | 50 - 60 ft/min |

| Material Thickness | Variable |

| Machine Weight | 15 tons |

| Machine Footprint | 60 ft x 12 ft |

| Main Power | 32 HP - 480V - 3 Phase |

| Forming Stations | 21 |

| Cutting Type | Hydraulic Shear |

| Control System | Delta PLC |

| Safety Covers | Yes |

The machine is capable of producing structural purlins with the following specifications:

Structural purlins produced by this machine are widely used in:

Q1: What profiles can this machine produce?

A1: The machine can produce structural purlins ranging from 5" to 12" in profile width, with variable material thickness to meet specific structural requirements.

Q2: Is this machine suitable for high-volume production?

A2: Yes, with a forming speed of 50-60 ft/min and 21 forming stations, it is designed for high-volume production.

Q3: What type of power supply is required?

A3: The machine operates on a 480V, 3-phase power supply with a main motor power of 32 HP.

Q4: Can the machine handle different material thicknesses?

A4: Yes, the machine is versatile and can handle variable material thicknesses to cater to different project needs.

Q5: Are there safety features included?

A5: Yes, the machine comes with safety covers to ensure operator protection and workplace safety.

Q6: What is the machine’s weight, and does it require a reinforced foundation?

A6: The machine weighs 15 tons and may require a reinforced foundation depending on the installation site.

Q7: Is the machine easy to maintain?

A7: Yes, with regular lubrication, periodic inspections, and servicing, the machine is easy to maintain and ensures long-term reliability.

Copyright 2026 © Machine Matcher.