To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

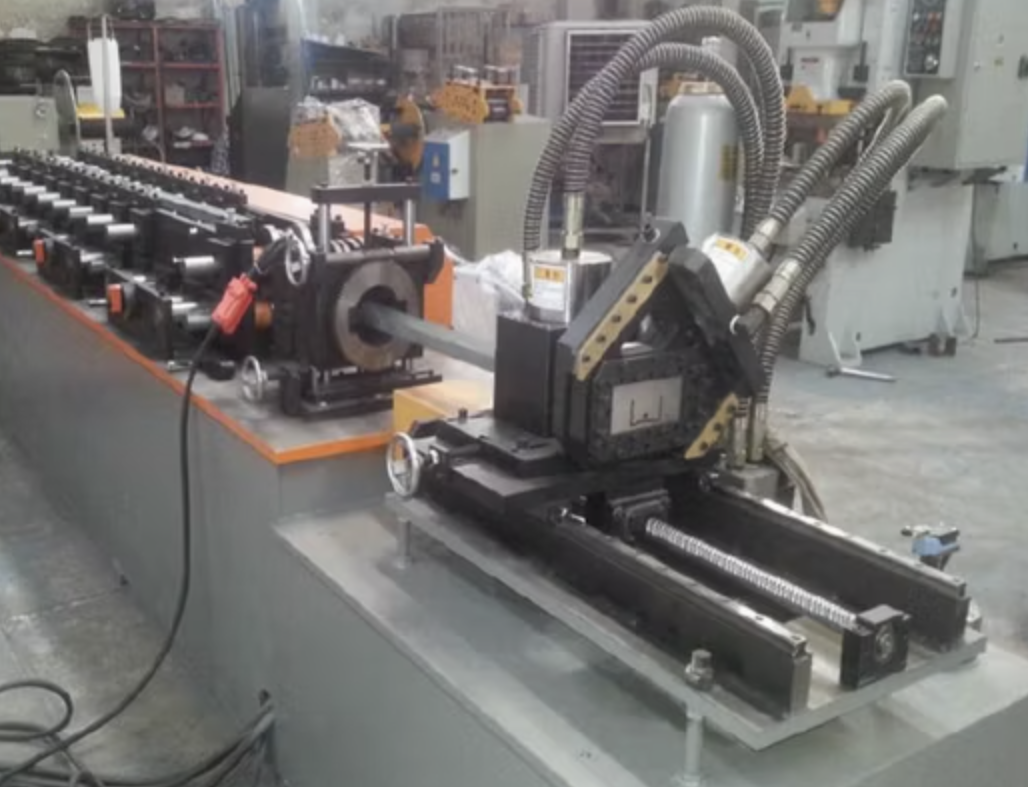

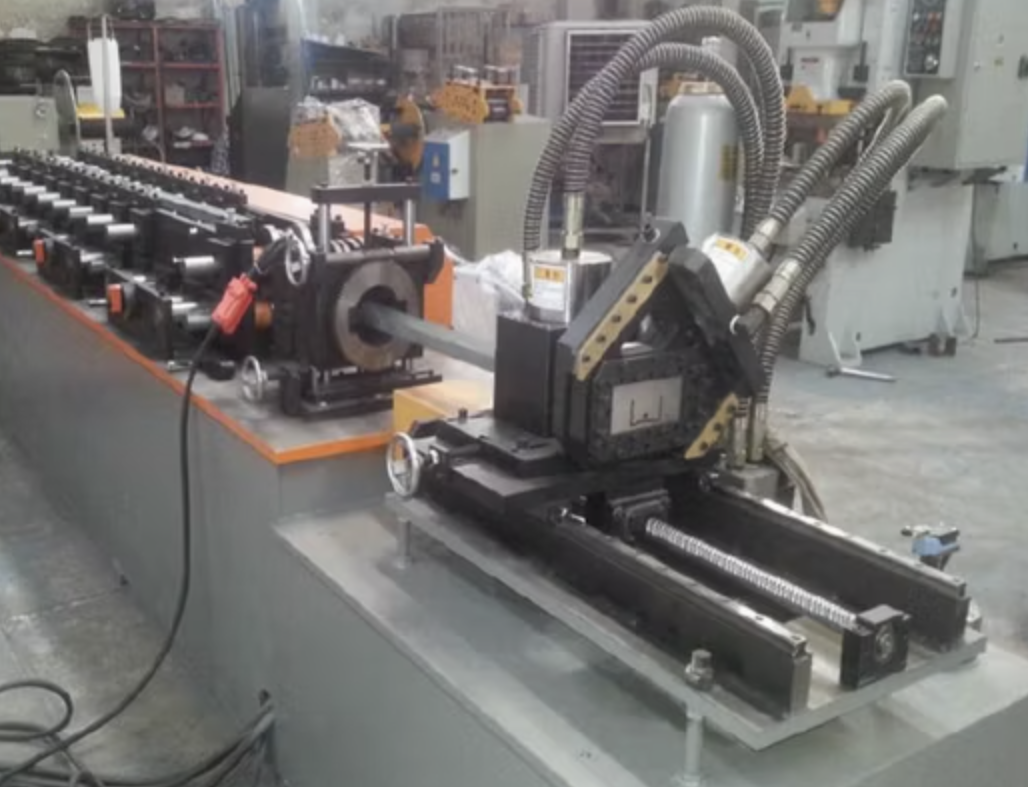

A Stud and Track Roll Forming Machine is a specialized piece of equipment designed for manufacturing steel stud and track profiles used in drywall framing systems. These machines are highly automated, ensuring precise, repeatable, and efficient production of lightweight steel profiles. They are commonly utilized in construction projects to create partitions, ceilings, and frameworks for drywall.

Stud and track profiles are essential for creating strong and durable structures, and their demand is high in Chile due to the country's construction boom and seismic considerations, which make lightweight steel framing an ideal choice.

Q1: Why should Chilean buyers invest in a Stud and Track Roll Forming Machine?

A: The machine offers unmatched efficiency in producing precise steel profiles needed for lightweight construction, which is a growing trend in Chile due to seismic concerns and rapid urbanization.

Q2: Can the machine be customized for different profile sizes?

A: Yes, the machine can be adjusted to produce a wide range of stud and track widths and thicknesses to meet diverse construction needs in Chile.

Q3: What materials are compatible with this machine?

A: The machine works well with galvanized steel, cold-rolled steel, and other lightweight steel materials commonly used in Chilean construction.

Q4: How is the machine powered, and is it compatible with Chilean electrical standards?

A: The standard power requirement is 380V, 50Hz, 3-phase, which aligns with Chilean electrical systems. Customizations are available for other power setups.

Q5: What is the average production speed?

A: The standard production speed is 20-30 m/min, with options for higher speeds up to 50 m/min depending on machine configuration.

Q6: Are there any additional costs associated with setup and installation?

A: While the machine comes with a detailed manual and remote support, on-site installation and training services can be arranged for an additional fee.

Q7: What is the typical lead time for delivery to Chile?

A: Depending on the customization level, the machine can be delivered to Chile within 8-12 weeks from the date of order confirmation.

Q8: What is the warranty period?

A: The standard warranty period is 12 months from installation or 18 months from the shipping date, whichever comes first.

Q9: What maintenance does the machine require?

A: Regular maintenance includes lubrication of moving parts, checking and replacing hydraulic oil, inspecting the cutting system, and cleaning the rollers.

Q10: How does this machine contribute to eco-friendly construction in Chile?

A: Lightweight steel framing is a sustainable construction method that reduces material waste and energy consumption, aligning with Chile’s growing focus on green building practices.

For buyers in Chile, investing in a Stud and Track Roll Forming Machine ensures access to high-quality construction materials, supporting faster and more efficient project completions. For further inquiries, specifications, or a tailored quote, please reach out to your trusted roll forming machine supplier.

Copyright 2026 © Machine Matcher.