To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Stud and Track Roll Forming Machine – For Saudi Arabia

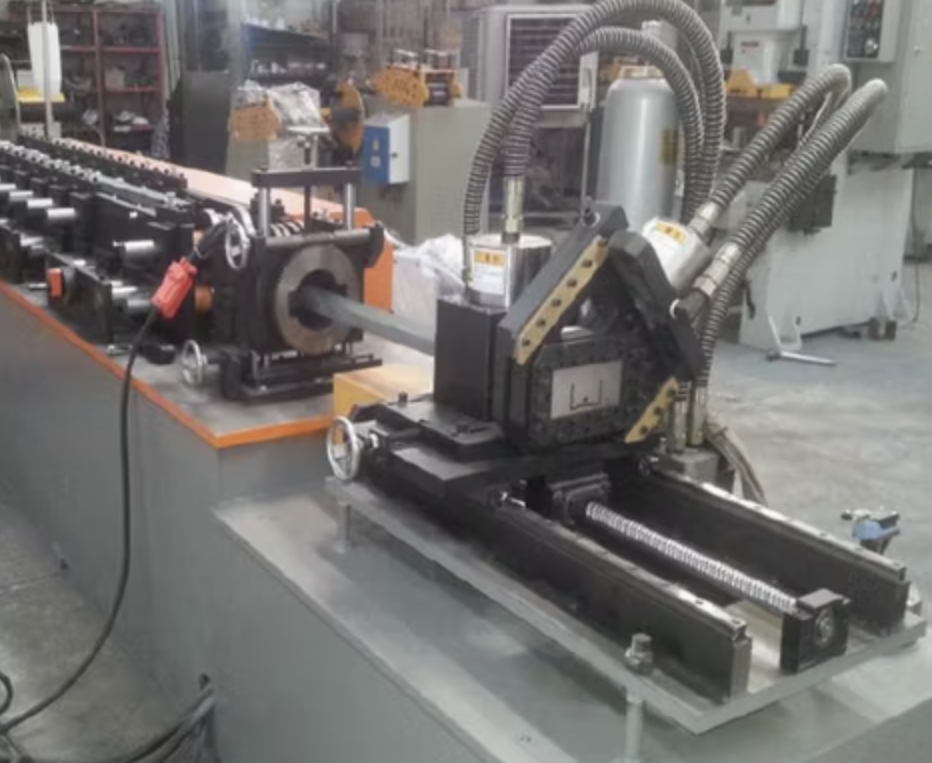

The Stud and Track Roll Forming Machine is a high-performance, precision-engineered solution designed for manufacturers and contractors operating in Saudi Arabia’s dynamic construction and steel industries. This machine is ideally suited for producing lightweight steel framing components such as studs and tracks, which are essential in drywall partition systems and ceiling framing structures.

Whether you're serving the residential, commercial, or industrial sectors, this roll forming machine is engineered to meet Saudi Arabia's local building codes, climatic conditions, and industry-specific standards. From Riyadh to Jeddah and across the GCC region, this machine provides a reliable, durable, and scalable solution for steel framing production.

This stud and track roll forming machine is custom-built and fully automated for consistent performance in high-demand environments. Designed with robust construction and powered by 25kW, the machine handles coil material thicknesses ranging from 0.5mm to 1.2mm, making it suitable for both lightweight interior partition frames and heavier structural elements.

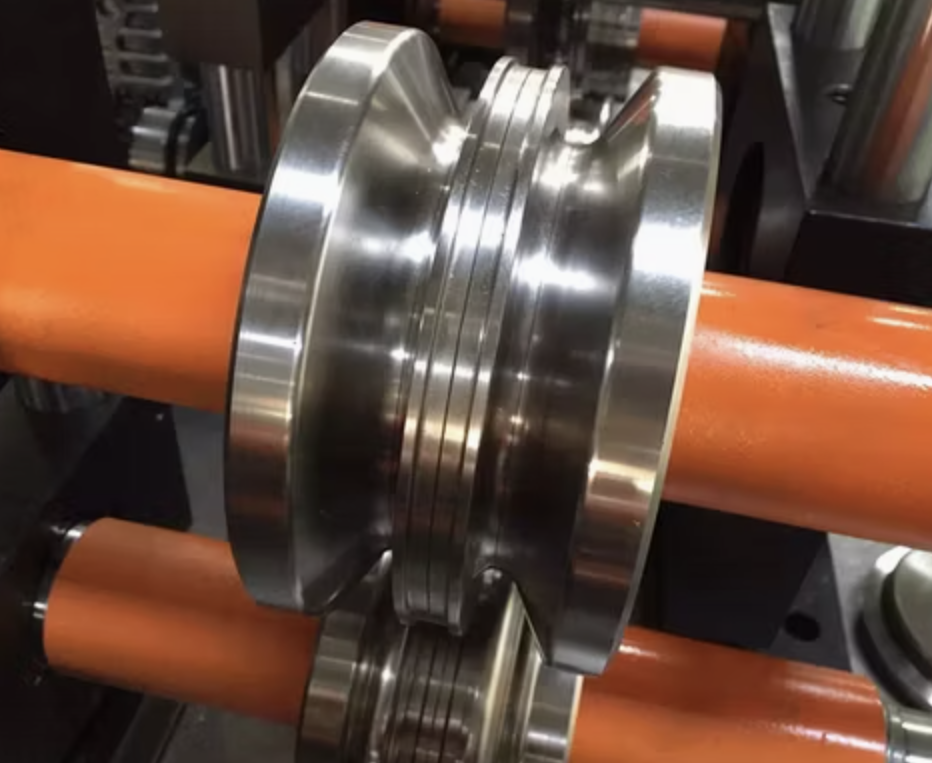

The forming rollers, made from hardened D2 steel, ensure precise profile shaping, reduced maintenance, and extended machine life. Chrome-treated 40Cr shafts provide enhanced stability during high-speed production, ensuring smooth operation even during extended runs.

Its efficient footprint (20 × 2 meters) makes it easy to install in both small-scale and large-scale production facilities. With a flexible production speed of 20–40 meters per minute, this machine balances speed and quality to deliver reliable output.

This machine is ideal for use in:

Saudi Arabia’s increasing demand for modern construction methods, including prefabricated and lightweight steel structures, makes this machine a valuable asset for manufacturers in the region.

All machines are new and custom-built based on your unique profile drawings and specifications. Machine Matcher will ship the machine directly from our manufacturing partner to your location in Saudi Arabia, ensuring a smooth and timely delivery process.

Pricing varies depending on selected optional extras, control systems, and profile customization. Please contact us for a tailored quote.

If you have profile drawings or any additional information that would help us provide the best quote, please send details to [email protected].

We supply roll forming machines to clients across the Middle East, Europe, Africa, Asia, North and South America, backed by a full range of machine sales, maintenance, repair, and setup services.

What types of profiles can this machine produce?

This machine is designed to produce steel stud and track profiles for wall partitions, ceilings, and framing systems. We can customize the profile design based on your drawings and building requirements.

Can this machine be customized for my project in Saudi Arabia?

Yes, all machines are custom-built to meet your project specifications and local Saudi building codes.

Is the machine easy to install?

Yes, it is delivered with clear instructions and can be installed with basic technical assistance. We also offer setup support if needed.

Do you offer training for operators?

Yes, basic training is included, and additional training can be arranged on request.

What is the lead time for delivery?

Delivery time depends on customization, but typically machines are built and shipped within 30–60 days.

Is technical support available in Saudi Arabia?

Yes, we offer global after-sales support including remote troubleshooting and on-site service in Saudi Arabia.

What industries is this machine suitable for in Saudi Arabia?

It is perfect for the construction, prefab housing, drywall system, and interior partition industries.

For more information or to request a quote, reach out to our team today. Machine Matcher is your trusted global partner for precision roll forming solutions.

Copyright 2026 © Machine Matcher.