To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

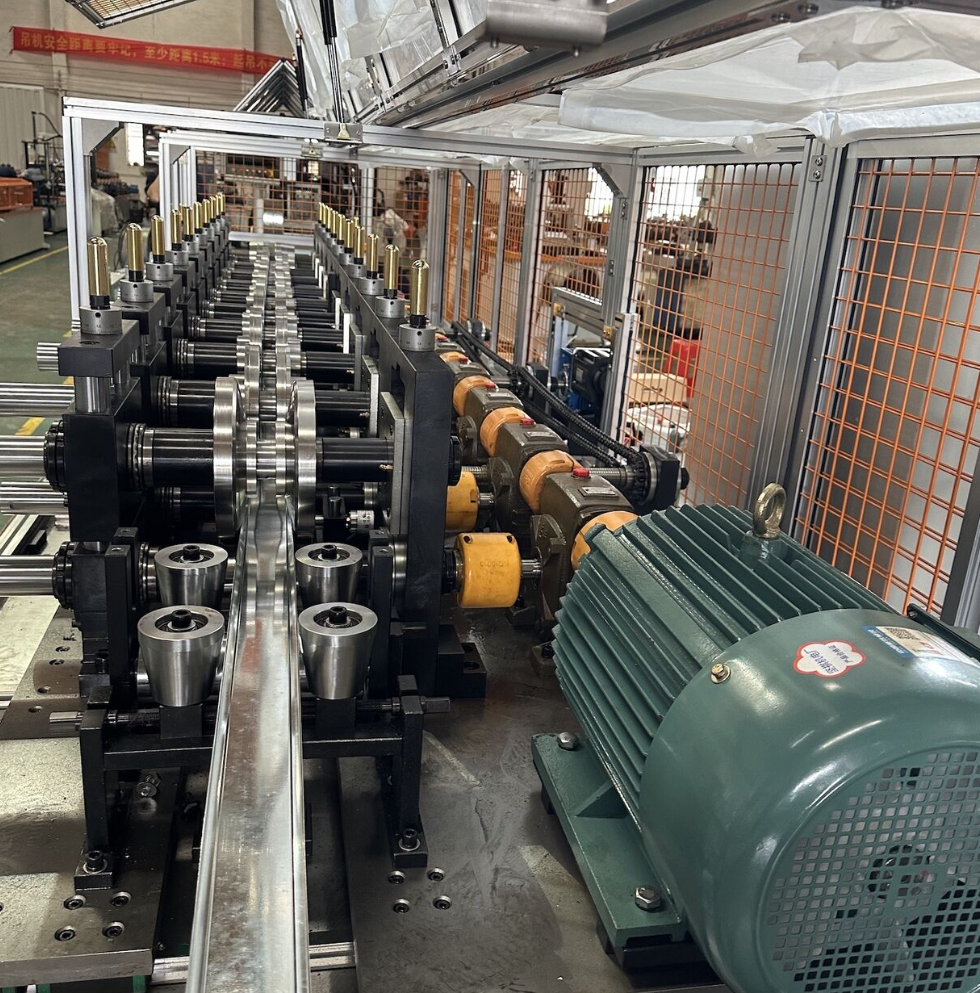

A Stud and Track Roll Forming Machine is a highly efficient industrial equipment designed to produce metal studs and tracks used in drywall and partition systems. These profiles are essential in the construction of lightweight steel framing for walls, ceilings, and partitions in residential, commercial, and industrial buildings. The machine is engineered for precision and high-speed production, ensuring consistent quality in mass manufacturing.

1. Machine Components:

2. Technical Specifications:

3. Optional Extras:

The demand for Stud and Track Roll Forming Machines is driven by the growth of lightweight steel framing in construction projects. Common applications include:

Q1: What is the advantage of using a Stud and Track Roll Forming Machine for construction projects?

A: This machine ensures consistent quality, reduces material waste, and enables mass production of framing components, which speeds up construction timelines.

Q2: Can this machine produce custom sizes for studs and tracks?

A: Yes, most Stud and Track Roll Forming Machines can be customized to produce specific sizes and profiles according to project requirements.

Q3: What materials are compatible with the machine?

A: It works with galvanized steel, aluminum, and stainless steel, with material thickness ranging from 0.5mm to 1.5mm.

Q4: What is the average production speed?

A: The machine typically operates at a speed of 30–50 meters per minute, depending on the complexity of the profile and the material.

Q5: How much space is needed to install the machine?

A: The machine typically requires a space of approximately 7 meters in length and 1.5 meters in width. Adequate additional space is recommended for operation and material handling.

Q6: Is maintenance difficult?

A: No, maintenance is straightforward and involves regular lubrication of moving parts, cleaning, and checking alignment and wear on rollers and dies.

Q7: Can it be shipped and installed in the USA?

A: Yes, these machines are shipped to the USA with detailed installation guides, and most manufacturers offer installation and training services.

By investing in a Stud and Track Roll Forming Machine, manufacturers in the USA can achieve efficient and high-quality production for lightweight steel framing, meeting the growing demands of the construction industry.

Copyright 2026 © Machine Matcher.