To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

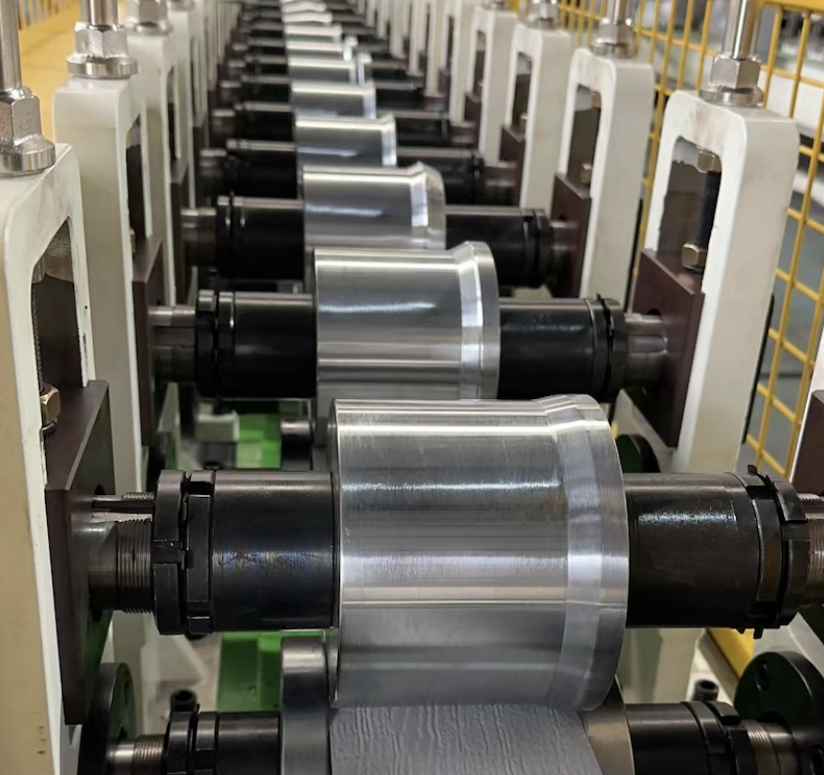

The T-Style drip edge roll forming machine is a specialized industrial equipment designed to manufacture drip edges used in roofing systems. The machine produces precise and consistent T-style drip edge profiles that are commonly used to direct water away from roofs and protect the underlying structure. These profiles are widely used in residential, commercial, and industrial roofing projects across the USA.

This machine is engineered for high efficiency, accuracy, and durability. It features advanced control systems for seamless operation and customization. The roll forming process ensures minimal material waste while delivering high-quality profiles that meet industry standards.

A: The T-style drip edge roll forming machine can process galvanized steel, aluminum, and stainless steel with thicknesses ranging from 0.3mm to 0.8mm.

A: The machine can produce drip edge profiles at speeds of up to 40 meters per minute, depending on the material and profile specifications.

A: Yes, the machine can be customized to produce specific T-style drip edge profiles according to project requirements.

A: It is equipped with safety guards, emergency stop buttons, and a user-friendly PLC system to minimize risks during operation.

A: Optional features include automatic stackers, remote PLC systems, and advanced material handling solutions like uncoilers and recoilers.

A: Yes, the machine is designed to integrate seamlessly with existing production setups for enhanced efficiency.

A: Yes, technical support and after-sales services are available across the USA, ensuring smooth operation and maintenance.

This comprehensive description and Q&A section provide all the necessary details about the T-style drip edge roll forming machine, making it an ideal solution for manufacturers and contractors in the USA roofing industry.

Copyright 2026 © Machine Matcher.