To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

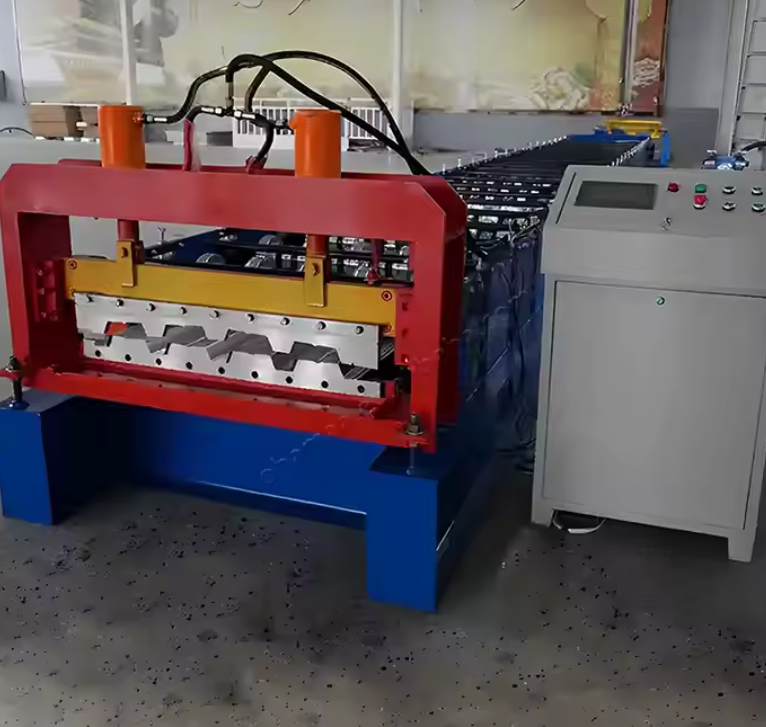

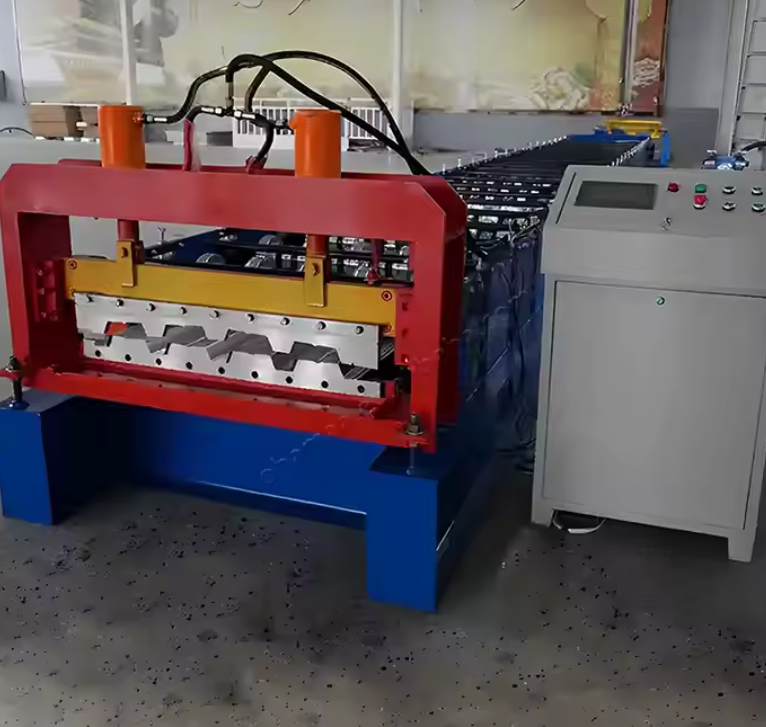

Type A Roof Deck Roll Forming Machine – UAE Market Overview

Powered by Machine Matcher

Machine Matcher is proud to offer custom-engineered Type A Roof Deck Roll Forming Machines tailored for the roofing and decking industry in the United Arab Emirates. Designed for high-efficiency production, this roll forming system is ideal for fabricating Type A roof decking panels commonly used in commercial, industrial, and infrastructure projects across the UAE. With precision forming, durable construction, and configurable options, this machine meets the growing demand for lightweight steel construction solutions in hot, arid environments like Abu Dhabi, Dubai, Sharjah, and other cities across the Emirates.

Location Served: Across the UAE – Abu Dhabi, Dubai, Sharjah, Ajman, and beyond

Machine Type: Fully automatic Type A Roof Deck Roll Forming Machine

Applications: Roofing systems, structural decking, industrial floors, commercial buildings

Operation: High-speed, automated metal forming for mass production

Material Support: Galvanized steel, cold rolled steel, and other standard building-grade coil materials

Warranty & Support: One-year warranty with robust after-sales service and remote support

The Type A Roof Deck Roll Forming Machine is a specialized solution engineered to fabricate 1.5-inch deep structural roof deck panels (also referred to as Type A decks). These panels are known for their structural integrity and are widely used in projects that require load-bearing support and integration with concrete or insulation systems. The machine operates with precision-forming rollers, a hydraulic cutting system, and advanced PLC control, ensuring that each panel meets stringent tolerances.

With increasing demand for fast and efficient construction in the UAE, this machine offers high-speed production, consistent quality, and minimal manual intervention. Whether used in commercial warehouses, industrial factories, or high-rise developments, it provides the reliability and scalability required in today’s construction environment.

Construction & Infrastructure

Commercial Real Estate

Warehousing & Industrial Buildings

Transport Terminals & Airport Hangers

Retail and Mega Malls

Oil & Gas Facilities with roofing systems

| Specification | Details |

|---|---|

| Machine Type: | Type A Roof Deck Roll Forming Machine |

| Production Speed: | 15–25 meters per minute |

| Material Thickness Range: | 0.75mm – 1.5mm |

| Material Width Range: | 1000mm – 1250mm (based on coil input) |

| Material Types: | Galvanized steel, Cold rolled steel |

| Material Yield Strength: | Up to 550 MPa |

| Roller Material: | High-grade GCr15 steel (heat-treated) |

| Roller Surface Treatment: | Hard chrome plating for wear resistance |

| Number of Forming Stations: | 18–24 stations (depending on profile design) |

| Roller Shaft Diameter: | 70mm–90mm |

| Shaft Material: | Solid 45# steel with precision machining |

| Main Drive Type: | Chain or gearbox drive (optional inline system) |

| Power (UAE Spec): | 380V, 3Phase, 50Hz |

| Motor Power: | 15kW–22kW main motor |

| Cutting Method: | Hydraulic post-cut with stop and cut sequence |

| Blade Material: | Cr12MoV high-strength steel |

| Control Type: | PLC with HMI touchscreen (Siemens/Delta) |

| Operating Mode: | Fully automatic with manual override |

| De-coiling System: | 5T–10T manual or hydraulic decoiler (optional) |

| Punching/Notching System: | Optional inline hydraulic punching system |

| Machine Frame: | Welded steel frame with stress relief treatment |

| Thickness of Frame Steel: | 20mm base structure for durability |

| Profile Shape: | Type A (1.5" depth), trapezoidal corrugation |

| Profile Width and Depth: | Approx. 965mm effective width, 38mm depth |

| Length Tolerance: | ±2.0mm |

| Safety Features: | Protective covers, Emergency Stop, Overload system |

Prices Start From: USD $65,000 (standard configuration)

What Affects Final Price:

Profile design and dimensions

Decoiler type (manual vs. hydraulic)

Inline punching systems or stackers

Servo motors or upgraded PLC controls

Automated stackers and coil handling systems

Shipping and delivery to your UAE location

Note: All machines are new and custom-built to meet your specific production requirements. We deliver to all Emirates and offer remote commissioning and setup assistance.

This machine is manufactured to order and delivered across the UAE, including Abu Dhabi, Dubai, Sharjah, Ras Al Khaimah, and Fujairah. All machines come with:

1-Year Warranty from Date of Dispatch

Expert Remote Installation Guidance

Ongoing Maintenance and Spare Parts Support

To receive the best quote, we recommend you send profile drawings and production requirements to:

[email protected]

Q1: What is the typical delivery time to the UAE?

A: Lead times range from 45–75 days depending on customization and shipping logistics.

Q2: Can this machine handle stainless steel or aluminum?

A: While it’s optimized for galvanized steel, we can configure it for aluminum or stainless upon request.

Q3: What kind of setup support do you offer?

A: We offer remote setup, operator training guides, and optional onsite assistance depending on location.

Q4: Is the machine CE or ISO certified?

A: Yes, our manufacturing partners provide CE and ISO certification for compliance and export documentation.

Q5: Can the machine profile be adjusted later?

A: No. Each machine is built to a specific profile. If multi-profile flexibility is needed, we recommend a cassette-type or quick-change tooling system (at extra cost).

Q6: How do I maintain this machine?

A: Routine lubrication, bolt tightening, roller cleaning, and checking hydraulic fluid levels every 250–300 hours is recommended. Full maintenance documentation is included.

Machine Matcher is your trusted partner for high-performance roll forming equipment in the UAE. We connect you to the most reliable manufacturers and guide you through specification, customization, delivery, and support—ensuring your project success with world-class equipment and professional service.

Ready to request a quote or need assistance?

Send your specifications or profile drawing to [email protected] and our team will respond within 24 hours.

Copyright 2026 © Machine Matcher.