To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

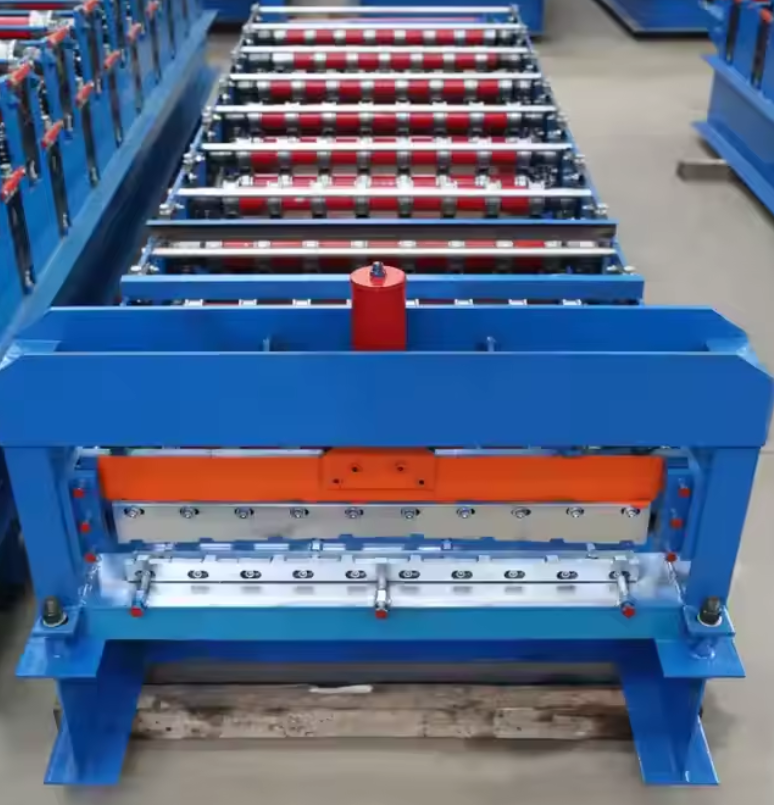

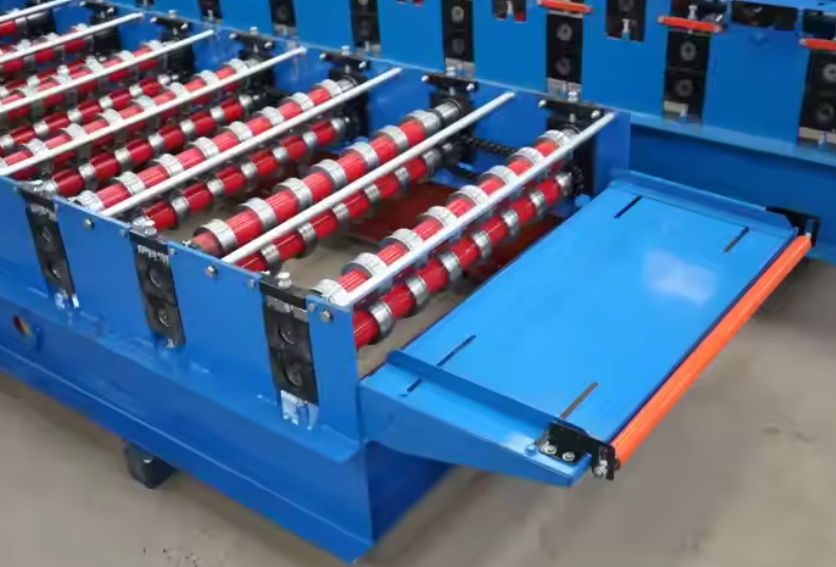

Type B Roof Deck Roll Forming Machine – United Arab Emirates (UAE)

Custom-Built for High-Performance Roofing Applications Across Abu Dhabi, Dubai, Sharjah & All Emirates

The Type B Roof Deck Roll Forming Machine is engineered for producing high-strength steel decking panels with a characteristic B-profile rib, widely used in commercial, industrial, and institutional roofing applications throughout the UAE. Known for its durability and versatility, the Type B roof deck provides excellent structural performance and serves as a superior substrate for waterproofing membranes and insulation systems.

This advanced roll forming machine is designed to meet the growing demand for localized, precision-formed metal roof decking. It offers high-speed continuous production, tight length tolerances, and customized profile dimensions, making it the ideal solution for UAE-based manufacturers, roofing contractors, and construction material suppliers.

Machine Matcher supplies this machine fully configured and tested, with delivery available anywhere in the UAE. All machines are new, custom-built to match your profile requirements, and supported by a 1-year warranty and technical maintenance program.

Commercial Construction (office buildings, malls, warehouses)

Industrial Infrastructure (factories, steel buildings, hangars)

Institutional Projects (hospitals, schools, stadiums)

Modular & Pre-engineered Building Systems

Roofing Contractors & Steel Decking Fabricators

Type B deck is favored in the UAE for its 1.5” deep ribs, 36” coverage, and compatibility with both steel trusses and concrete roofing systems.

| Specification | Details |

|---|---|

| Machine Type | Type B Roof Deck Roll Forming Machine |

| Production Speed | 12–20 meters/min (standard), up to 30m/min with high-speed configuration |

| Material Thickness Range | 0.75 mm to 1.5 mm |

| Material Width Range | 914 mm to 1220 mm |

| Material Types | Galvanized Steel (GI), Cold Rolled Steel (CR), Galvalume, PPGI |

| Material Yield Strength | Up to 550 MPa |

| Roller Material | GCr15 (high-grade bearing steel) |

| Roller Surface Treatment | Hard chrome plating for anti-rust and wear resistance |

| Number of Forming Stations | 20–26 stations (customizable) |

| Roller Shaft Diameter | 80 mm (standard) |

| Shaft Material | 45# steel, quenched and tempered |

| Main Drive Type | Gearbox-driven (for precision and power) |

| Power Supply (UAE Compatible) | 380V, 50Hz, 3-phase |

| Motor Power | 15–22 kW depending on configuration |

| Cutting Method | Hydraulic post-cut system |

| Blade Material | Cr12MoV, heat-treated |

| Control Type | PLC with HMI touchscreen (Siemens, Delta, or Mitsubishi) |

| Operating Mode | Fully automatic (feeding–forming–cutting) |

| De-coiling System | Hydraulic or manual decoiler (3–10 ton optional) |

| Punching/Notching System | Optional hydraulic pre-punching system |

| Machine Frame | Welded steel base with annealed structure |

| Thickness of Frame Steel | 20–25 mm sidewall thickness |

| Profile Shape | Type B Rib Roof Deck |

| Profile Width and Depth | 36” width, 1.5” rib depth (customizable) |

| Length Tolerance | ±1.0 mm |

| Safety Features | Fully enclosed safety guards, warning lights |

| Emergency Stop Button, Overload Protection System |

USD $85,000

(FOB price range based on standard configuration)

Profile customization (rib design, coverage width)

Speed and automation level

Brand of control system (Siemens, Mitsubishi, Delta, etc.)

Type of decoiler (manual vs. hydraulic)

Punching or notching systems

Coil handling and stacker systems

Country-specific compliance or certifications

To receive an accurate quotation tailored to your specifications, send your profile drawing and requirements to [email protected].

All machines are new and custom-built, shipped directly from our certified partner factories. Delivery and setup are available across the UAE, including:

Abu Dhabi

Dubai

Sharjah

Ajman

Ras Al Khaimah

Fujairah

Al Ain

1-Year Warranty from dispatch date

Remote technical support, spare parts availability

Optional setup and training packages in the UAE

Q1: What is the maximum material thickness this machine can handle?

A: The machine can handle material from 0.75 mm up to 1.5 mm, depending on your profile design and project needs.

Q2: Can I order a machine that produces a different width or rib height?

A: Yes. This machine is custom-built and we can adjust profile dimensions based on your drawing or sample.

Q3: Does the machine include a decoiler?

A: A manual or hydraulic decoiler is optional. Most clients in the UAE opt for a 5-ton hydraulic decoiler with speed control.

Q4: Is operator training provided?

A: Yes, remote training is included. On-site training and setup assistance in the UAE can be arranged upon request.

Q5: How long does it take to manufacture and ship to the UAE?

A: Standard production time is 40–60 days, followed by shipping and customs clearance. We offer full support throughout.

Q6: What is the difference between Type B and Type N deck?

A: Type B has 1.5” ribs and 36” coverage, making it ideal for roofs. Type N has 3” ribs for longer spans and heavier loads.

The Type B Roof Deck Roll Forming Machine is the perfect solution for UAE-based metal deck manufacturers, roofing system suppliers, and construction material companies. With high-speed precision forming, localized power compatibility, and profile customization, it provides a complete solution for producing durable and standardized B-deck roofing panels.

For the best quote, email your profile drawing, thickness, material type, and target output to:

[email protected]

Copyright 2026 © Machine Matcher.