To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

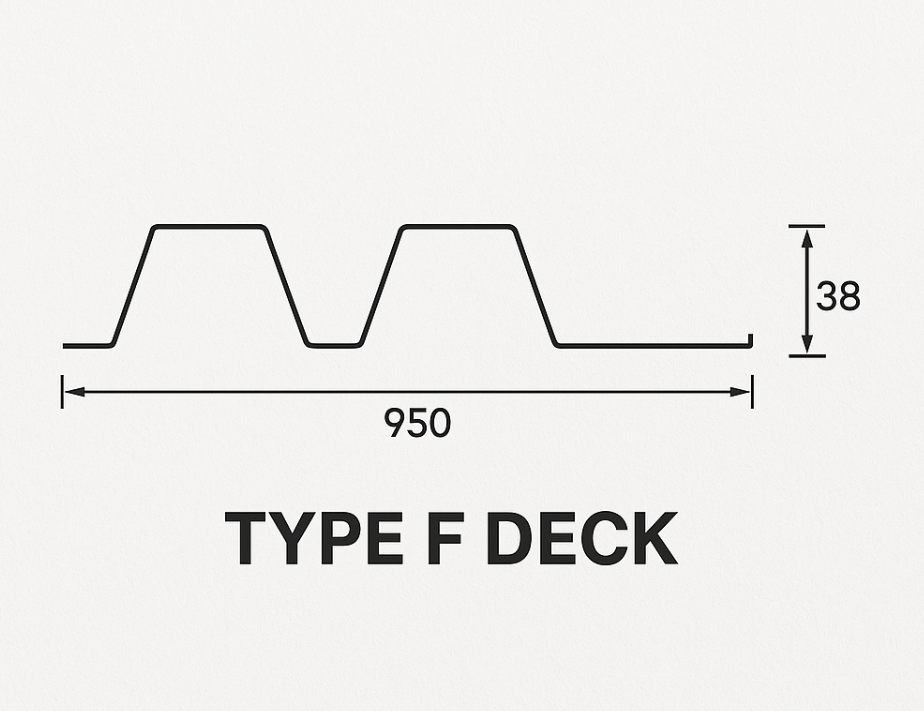

Type F Roof Deck Roll Forming Machine – UAE Market Specification and Description

Available across Abu Dhabi, Dubai, Sharjah, and all regions of the United Arab Emirates

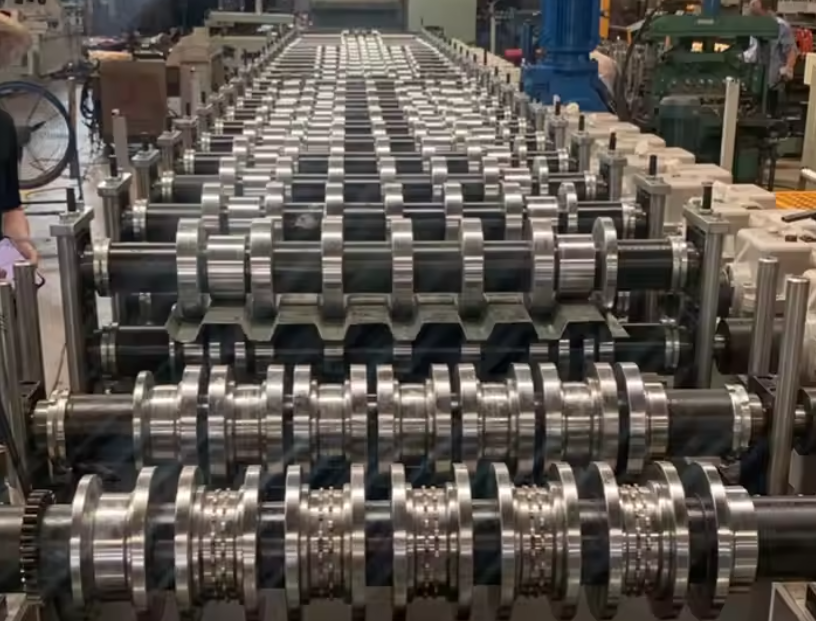

The Type F Roof Deck Roll Forming Machine is a high-precision industrial forming system designed specifically for the production of F-deck roof panels, commonly used in commercial and industrial buildings across the UAE. These roof deck profiles are valued for their enhanced structural strength and load-bearing capabilities, making them essential in the construction of warehouses, high-rise commercial towers, malls, stadiums, and other large-scale infrastructure projects.

Engineered for continuous and automated production, the Type F deck machine accommodates a range of steel coils, delivering consistent output with minimal manual intervention. Its robust design ensures superior panel accuracy and strength while meeting UAE’s local building standards and extreme climate conditions.

This machine is a key asset in the following sectors:

Construction & Infrastructure

Steel Building Manufacturing

Commercial Roofing Contractors

Industrial Sheds and Warehousing

Modular Building Fabricators

Metal Decking Supply for UAE's high-rise developments

Its profile provides a stable base for concrete and insulation layers and supports various waterproofing systems. The Type F deck is particularly popular in roofing and diaphragm applications where rigidity and spanning capability are required.

| Specification | Detail |

|---|---|

| Machine Type | Type F Roof Deck Roll Forming Machine |

| Production Speed | 15–25 meters/min (adjustable) |

| Material Thickness Range | 0.8mm – 1.5mm |

| Material Width Range | 1000mm – 1250mm |

| Material Types | Galvanized Steel (GI), Galvalume, PPGI |

| Material Yield Strength | Up to 550 MPa |

| Roller Material | High-grade GCr15 steel |

| Roller Surface Treatment | Hard chrome plating (0.05mm) |

| Number of Forming Stations | 22–28 stations (based on final profile) |

| Roller Shaft Diameter | 75mm |

| Shaft Material | High tensile steel, heat-treated |

| Main Drive Type | Gearbox-driven chain or direct gear drive |

| Power (UAE Standard) | 380V / 50Hz / 3 Phase |

| Motor Power | 15kW – 22kW depending on configuration |

| Cutting Method | Hydraulic post-cutting |

| Blade Material | Cr12Mov (hardened) |

| Control Type | PLC Control System (Siemens/Delta/Mitsubishi) |

| Operating Mode | Automatic with manual override |

| De-coiling System | 5-ton hydraulic or manual uncoiler |

| Punching/Notching System | Optional hydraulic system |

| Machine Frame | Welded H-beam base frame |

| Thickness of Frame Steel | 20mm |

| Profile Shape | Type F Roof Deck (wide rib profile) |

| Profile Width and Depth | Approx. 950mm effective width x 38mm depth |

| Length Tolerance | ±1.0mm |

| Safety Features | Full emergency stop system, guard covers |

| Protective Covers/Guards | Included (standard across the line) |

| Emergency Stop Button | Yes (multiple points along the line) |

| Overload Protection System | Yes |

Prices start from: $65,000 USD

Final pricing depends on:

Length of production line

Roller material upgrade (e.g., tungsten coating)

Optional extras (e.g., auto stackers, notching units, advanced PLC control)

Uncoiling and coil handling requirements

Shipping and installation location within the UAE

For an accurate quote, send your profile drawing, expected coil specs, power supply, and target production speed to:

[email protected]

All machines are new and custom-built to match your specific project requirements and are delivered anywhere across the United Arab Emirates, including Abu Dhabi, Dubai, Sharjah, Ajman, Ras Al Khaimah, and beyond.

Machine Matcher ensures:

1-Year Manufacturer Warranty

Spare Parts & Maintenance Support

Installation & Commissioning Assistance

Operator Training Available (on-site or remote)

Q1: What is the difference between Type F and other roof deck profiles?

A: Type F roof decks typically have narrower rib spacing and shallower depth compared to Type B or N. They’re ideal for applications requiring enhanced support for roofing insulation and waterproofing systems, especially in commercial roofing in the UAE.

Q2: Can this machine handle aluminum or stainless steel?

A: This model is optimized for GI and PPGI steel. Aluminum and stainless steel can be processed with specific roller materials and modifications—please mention this when requesting a quote.

Q3: How long does it take to deliver the machine in the UAE?

A: Lead time ranges from 60 to 90 days, depending on configuration, followed by customs clearance and delivery to site.

Q4: Can the machine be customized for different deck sizes or rib patterns?

A: Yes. Each machine is fully customizable based on your drawing or local standard. You can send your required profile sketch to [email protected].

Q5: Is installation support available in Dubai and Abu Dhabi?

A: Yes. Machine Matcher offers local and remote installation support throughout the UAE. On-site support is available upon request.

Coil Car / Coil Tipper

Automatic Hydraulic Uncoiler

Servo Feeder for Punching

Flying Cut-Off System

Automatic Stacker

Remote Monitoring PLC System

Leveling Unit

In-line Embossing Unit (for anti-slip surface)

The Type F Roof Deck Roll Forming Machine is a precision-engineered solution for contractors and manufacturers building the UAE’s commercial infrastructure. With its flexibility, high-speed production, and durable build, it provides an edge in a competitive construction market.

Contact Machine Matcher today to configure your machine and secure your place in the region’s expanding construction boom.

Email: [email protected]

Copyright 2026 © Machine Matcher.