To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

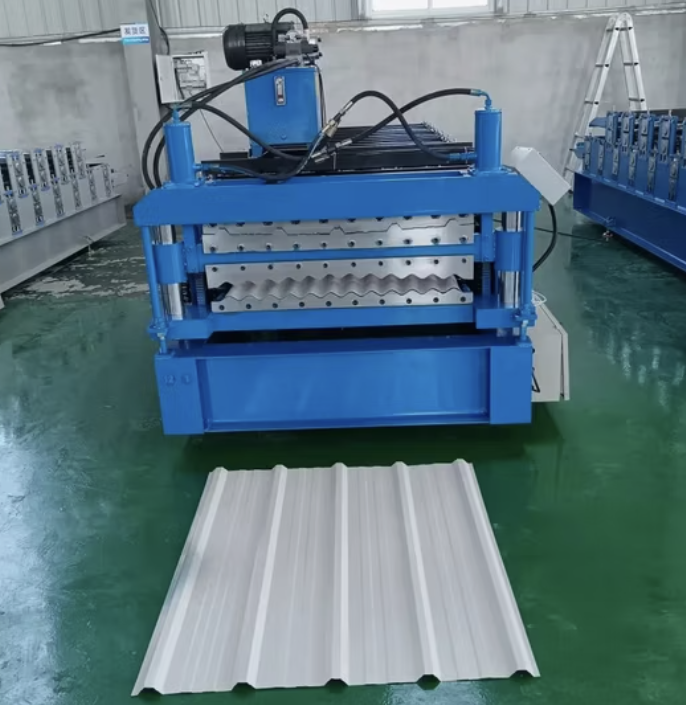

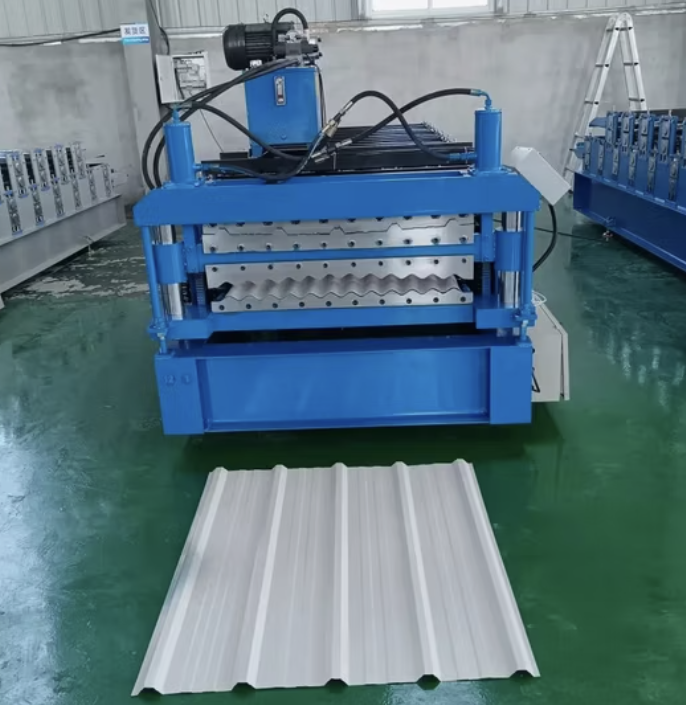

A wall panel roll forming machine is a highly specialized piece of equipment designed to produce wall panels in various profiles. These machines are widely used in construction for manufacturing walls and building facades, offering high precision and speed for mass production of metal wall panels. Known for their durability, efficiency, and low maintenance requirements, wall panel roll forming machines play a crucial role in the structural and aesthetic aspects of modern building projects.

The wall panel roll forming machine transforms metal coils into specific wall panel profiles through continuous bending and rolling. This process ensures high accuracy in both size and shape, resulting in panels that meet strict standards for industrial, commercial, and residential construction projects. Wall panel machines are configured to handle various materials, including steel, aluminum, and galvanized metals, allowing for versatility in application.

Typically, these machines are equipped with a PLC (Programmable Logic Controller) system, which automates the cutting, punching, and rolling processes, ensuring consistent quality and reducing human error. They are designed with safety enclosures and protective guards, making them both efficient and safe to operate.

Setting up a wall panel roll forming machine involves the following steps:

Q: What types of profiles can a wall panel roll forming machine produce?

A: Wall panel roll forming machines can be customized to produce a wide range of profiles, including ribbed, corrugated, and flat panels. This flexibility allows for various architectural applications and customer-specific designs.

Q: Can the machine handle different material thicknesses?

A: Yes, wall panel roll forming machines are built to accommodate varying thicknesses, typically from 0.3 to 1.5 mm. The machine settings can be adjusted to ensure high-quality results regardless of material thickness.

Q: How is the machine controlled?

A: The machine is equipped with a PLC control system, which automates the cutting, punching, and forming processes, making it easy to set precise parameters for each batch and ensuring consistent output quality.

Q: Are there any optional extras available with this machine?

A: Yes, optional extras include stackers for automatic stacking of finished panels, remote PLC systems for easy troubleshooting, and coil handling systems for better material management.

Q: How fast can the machine produce wall panels?

A: The machine typically operates at a speed of 10 - 15 meters per minute, but speed can vary based on material type, profile complexity, and machine specifications.

Q: What industries are the primary users of wall panel roll forming machines?

A: Wall panel roll forming machines are popular in the construction industry, particularly for residential, commercial, and industrial buildings. They are often used to produce wall panels for modern facades and other structural components.

Q: Is it possible to change profiles on the same machine?

A: Some machines are designed with interchangeable tooling or modular systems that allow users to switch profiles. However, it may require additional parts or adjustments depending on the desired profile change.

Q: What are the power supply requirements?

A: Most wall panel roll forming machines operate on a 380V/50Hz power supply, but the voltage can be customized to meet local standards. It’s essential to confirm the power requirements before installation.

Q: What is the maintenance schedule for this machine?

A: Regular maintenance is recommended every few months, including lubrication, inspection of rollers, hydraulic system checks, and testing of safety features. A detailed maintenance guide is typically provided with the machine.

Copyright 2025 © Machine Matcher.