To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

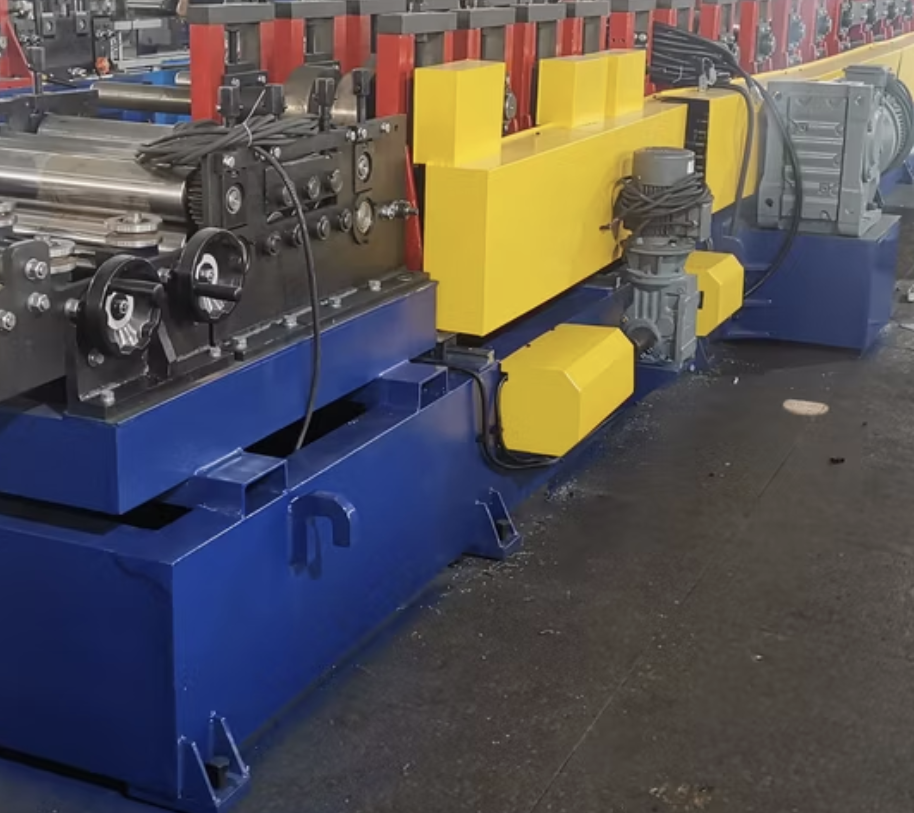

The Z Purlin Roll Forming Machine is designed specifically for producing Z-shaped purlins, which are essential in the construction industry for supporting walls and roofs. Z purlins provide structural strength while being lightweight, making them a popular choice for modern construction. These machines can be customized to produce Z purlins of various sizes and thicknesses, suitable for different applications.

The Z Purlin Roll Forming Machine is typically a fully automated system that includes a series of rollers, a punching mechanism, and a cutting system, all controlled by a PLC (Programmable Logic Controller). The machine is designed to handle high production demands with precision, ensuring each purlin meets strict quality standards. Operators can adjust settings to produce Z purlins of varying depths, widths, and thicknesses, making it a versatile solution for different construction requirements.

This roll forming machine can operate at a high speed, providing efficient production with minimal manual intervention. With its automated punching and cutting features, the Z Purlin Roll Forming Machine reduces labor costs and improves productivity, making it an ideal investment for construction firms, metal fabricators, and industrial suppliers.

Q1: What materials can be processed with the Z Purlin Roll Forming Machine?

A1: The Z Purlin Roll Forming Machine is primarily used to process metals like galvanized steel, mild steel, and aluminum, typically with a thickness range from 1.5 mm to 3.0 mm. The machine is compatible with other metals as long as they fall within the thickness range.

Q2: Can the machine produce different sizes of Z purlins?

A2: Yes, the machine is designed to produce Z purlins of various sizes. Adjustments can be made to width, depth, and material thickness to accommodate different construction requirements. This versatility makes it suitable for projects that require multiple sizes.

Q3: What safety features does this machine have?

A3: The Z Purlin Roll Forming Machine includes safety guards around moving parts, such as the rollers and cutting system, to protect operators. It also has emergency stop buttons and may include enclosures that provide additional safety.

Q4: How is the machine controlled?

A4: The machine is controlled via a PLC system with a touchscreen interface, allowing operators to easily set parameters, adjust sizes, and monitor the production process. The system also enables quick adjustments and troubleshooting.

Q5: What is the typical production speed of this machine?

A5: The machine operates at an average speed of 15 to 20 meters per minute, depending on material thickness, punching requirements, and other factors. This allows for efficient production without compromising on quality.

Q6: Is it possible to add a punching pattern to the Z purlins?

A6: Yes, the machine includes a hydraulic punching system that can be customized to produce different hole patterns on the Z purlins. This feature is highly useful for applications where specific attachment points are needed.

Q7: What optional extras are available for the machine?

A7: Optional extras include stackers for organized output, remote PLC control systems for easier operation, and coil car tippers for more efficient material handling. These add-ons can improve productivity and streamline the production process.

Q8: What maintenance does the Z Purlin Roll Forming Machine require?

A8: Routine maintenance includes regular lubrication of moving parts, inspection and replacement of worn-out rollers, checking hydraulic fluids, and ensuring the PLC system is functioning correctly. Keeping up with maintenance helps extend the machine’s lifespan and ensures consistent production quality.

The Z Purlin Roll Forming Machine is a valuable asset for any company involved in metal fabrication or construction, offering flexibility, precision, and efficiency in producing Z purlins essential for structural support.

Copyright 2026 © Machine Matcher.