Posted on Tuesday, April 25, 2023

Roll forming machines play an essential role in the manufacturing and construction sectors in Cyprus. With the country's booming construction industry and increasing demand for high-quality metal profiles, the use of roll forming machines is steadily rising. This article explores the most popular roll forming machines used in Cyprus, along with detailed specifications, industry applications, maintenance requirements, troubleshooting, and setup procedures. We will also cover how Machine Matcher can assist you in choosing the best machine to suit your profile needs.

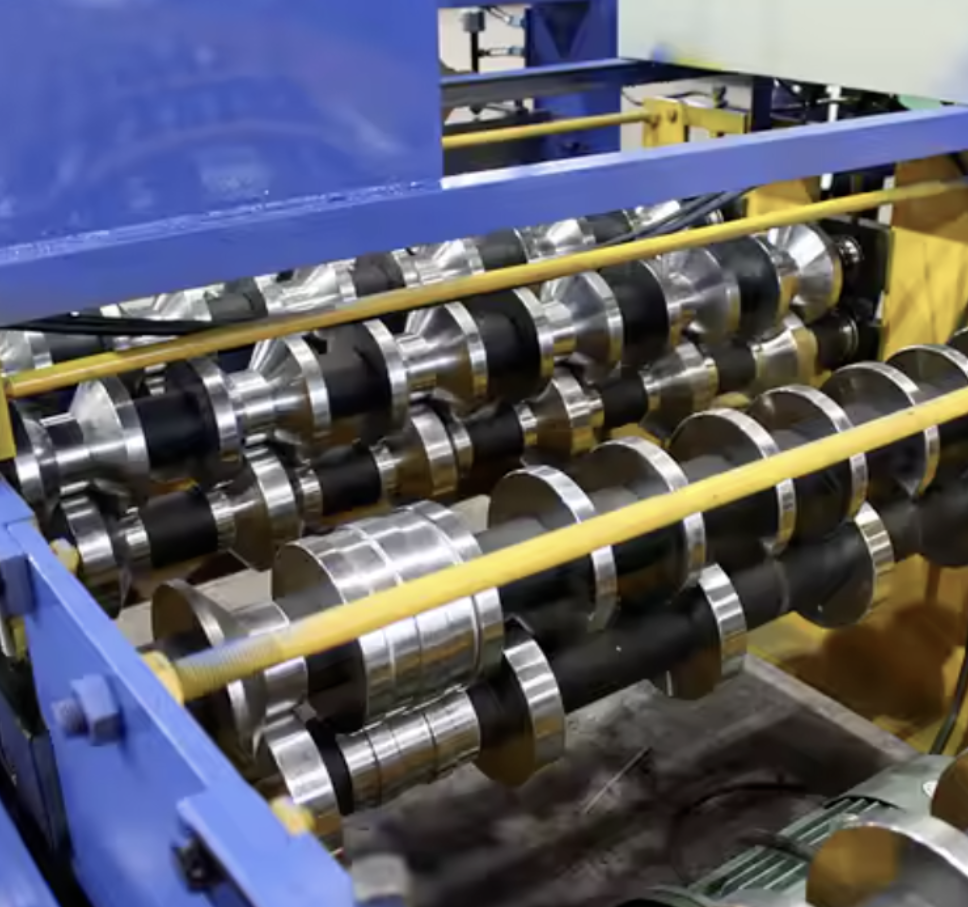

Roofing Sheet Roll Forming Machines

Specifications:

Roller Material: High-grade chromium steel (GCr15)

Hydraulic Cutting System: 5–12 MPa pressure

Frame Structure: H-beam welded base frame

PLC System: Siemens or Mitsubishi with user-friendly controls

Machine Speed: 8–15 meters per minute

Profiles Used: Corrugated sheets, trapezoidal profiles, standing seam panels

Industries: Construction, commercial roofing, residential projects

Main Cities/Areas: Nicosia, Limassol, Larnaca, Paphos

C Purlin and Z Purlin Roll Forming Machines

Specifications:

Roller Material: Cr12Mov steel with heat treatment

Cutting Mechanism: Hydraulic punching and cutting

Frame Size: Heavy-duty welded frame

Servo Motor: Yaskawa or equivalent

PLC System: Delta or Siemens with touch screen interface

Machine Speed: 10–25 meters per minute

Profiles Used: C and Z purlins of different sizes and thicknesses

Industries: Industrial warehouses, steel structures, solar panel mounting

Main Cities/Areas: Limassol, Famagusta, Paralimni

Decking Roll Forming Machines

Specifications:

Roller Material: GCr15 heat-treated steel

Hydraulic Cutting System: 12 MPa pressure

Frame Structure: H-beam base frame with reinforced construction

PLC System: Siemens or Omron with auto-correct function

Machine Speed: 8–20 meters per minute

Profiles Used: Floor decking panels, steel decking for bridges

Industries: Commercial buildings, residential high-rises, infrastructure projects

Main Cities/Areas: Nicosia, Limassol, Ayia Napa

Metal Stud and Track Roll Forming Machines

Specifications:

Roller Material: Cr12 with hard chrome plating

Cutting Mechanism: Servo motor and hydraulic cutting

PLC System: Mitsubishi with automatic error detection

Machine Speed: 30–45 meters per minute

Profiles Used: Drywall studs, tracks, furring channels

Industries: Interior construction, drywall partitioning

Main Cities/Areas: Paphos, Larnaca, Protaras

Highway Guardrail Roll Forming Machines

Specifications:

Roller Material: GCr15 steel, hardened for wear resistance

Hydraulic Cutting System: High-pressure with automated cutting

PLC System: Schneider or Siemens with smart controls

Machine Speed: 8–12 meters per minute

Profiles Used: W-beam and thrie-beam guardrails

Industries: Road infrastructure, safety barriers

Main Cities/Areas: Rural highways, coastal roads, urban zones

Construction and Roofing: Production of roofing sheets, wall panels, and decking profiles for residential, commercial, and industrial buildings.

Steel Structures: Manufacturing purlins and structural profiles used in steel frame buildings.

Infrastructure Projects: Production of guardrails for road safety, contributing to enhanced public infrastructure.

Interior Partitioning: Metal stud and track systems for interior wall systems in commercial and residential spaces.

Uncoiling and Feeding:

Position the steel coil on the uncoiler.

Ensure the feeding system aligns the material into the roll forming mill.

Roll Forming and Cutting:

Rollers progressively shape the metal into the desired profile.

The hydraulic cutting system ensures precision cutting to specified lengths.

Punching and Notching:

For profiles that require holes or slots, the punching system activates during roll forming.

Stacking and Packaging:

Finished profiles are automatically stacked and prepared for transportation.

Regular Lubrication:

Lubricate rollers, shafts, and cutting systems to reduce wear and tear.

Inspection of Hydraulic Systems:

Monitor pressure levels and replace hydraulic oil as needed.

Roller Alignment Checks:

Ensure rollers remain aligned to prevent defects in profile shaping.

Cleaning and Debris Removal:

Clean debris and metal particles to avoid damage to the rollers and cutting system.

Software and PLC Updates:

Update PLC software periodically for optimal system performance.

Misalignment of Profiles:

Check roller alignment and adjust tension settings.

Inconsistent Cutting Lengths:

Inspect the PLC system for parameter errors.

Hydraulic Pressure Drops:

Check hydraulic fluid levels and replace if necessary.

Roller Wear and Tear:

Replace worn-out rollers and perform regular inspections.

Material Thickness Constraints: Limited to specific thickness ranges depending on the machine type.

High Initial Investment: Advanced roll forming machines require a higher upfront investment.

Profile Design Restrictions: Complex profiles may require custom roll tooling, adding to operational costs.

High Efficiency and Consistency: Produces uniform profiles with minimal errors.

Reduced Waste and Scrap: Roll forming minimizes raw material waste.

Flexibility in Profile Designs: Machines can handle multiple profiles with quick changeover.

Cost-Effective Production: Suitable for high-volume production with lower operational costs.

Site Preparation:

Ensure the installation site has a leveled surface and adequate space for the machine and coil handling systems.

Machine Assembly:

Position the roll forming machine, uncoiler, and cutting system properly.

Connect power and hydraulic systems.

Calibration and Testing:

Calibrate rollers, PLC settings, and cutting mechanisms.

Perform test runs to ensure accurate profile shaping.

Operator Training:

Train operators on safety procedures and machine operation.

ISO 9001: Quality management systems to ensure consistent product quality.

CE Certification: Compliance with European safety and environmental standards.

ASTM Standards: Compliance with international standards for material specifications and performance.

Roofing Sheet Roll Forming Machines: $20,000 to $100,000

C and Z Purlin Roll Forming Machines: $25,000 to $120,000

Decking Roll Forming Machines: $30,000 to $150,000

Metal Stud and Track Roll Forming Machines: $15,000 to $80,000

Highway Guardrail Roll Forming Machines: $50,000 to $200,000

Cyprus primarily imports roll forming machines from international manufacturers in China, Italy, Turkey, and Germany. However, some local suppliers provide machine setup, maintenance, and after-sales support.

Machine Matcher specializes in connecting buyers with the most suitable roll forming machines based on their profile needs. Our experts analyze your production requirements, material specifications, and budget constraints to recommend the best machine. We ensure:

Inspection and Quality Checks: Every machine undergoes rigorous quality checks to ensure compliance with international standards.

Customized Solutions: Tailored machine options based on profile designs and desired production speed.

Logistics and Delivery: We handle machine shipping and delivery, ensuring smooth commissioning and operation.

After-Sales Support: Ongoing maintenance and technical support to maximize machine performance.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.