Posted on Monday, May 26, 2025

When purchasing a roll forming machine—whether new or used—it's crucial to consider the electrical setup to ensure seamless integration into your facility. Proper electrical installation not only guarantees optimal performance but also ensures safety and compliance with local regulations.

Before installation, thoroughly examine the machine's electrical requirements:

Voltage: Commonly 220V, 380V, or 415V.

Frequency: Typically 50Hz or 60Hz.

Phase: Usually 3-phase.

Power Rating: Specified in kilowatts (kW).JB Pub Samples

Ensure your facility's power supply matches these specifications to prevent operational issues.

Engage a certified electrician experienced in industrial machinery installations. Their expertise should include:

Understanding of 3-phase power systems.

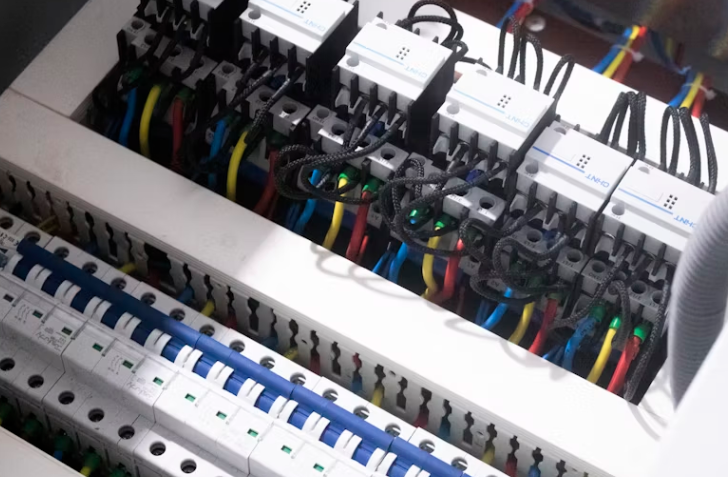

Proficiency in wiring Programmable Logic Controllers (PLCs), inverters, motors, and control panels.

This step is vital for safety, maintaining machine warranties, and adhering to local electrical codes.

Your electrician will:

Install appropriate circuit breakers or disconnect switches.

Connect the machine to the main power panel.

Implement overload protection mechanisms.

Ensure proper grounding/earthing to mitigate electrical hazards.

Proper grounding is essential to avoid electrical hazards .Machine Matcher

Some machines may arrive with separate control panels. The electrician should:

Connect the main power cable to the PLC panel.

Verify motor phase rotation, especially for drive motors, hydraulic pumps, and decoilers.

Test voltage and amperage during initial startup to ensure proper operation.

Coordinate with your machine supplier for commissioning support. During this phase:

Confirm all wiring and motor rotations are correct.

Test safety systems, including emergency stops and guards.

Conduct dry runs (without material) followed by actual production tests.

This ensures the machine operates safely and efficiently .

Maintain comprehensive records of the installation:

Updated wiring diagrams.

Details of breaker sizes and load ratings.

Inspection and installation reports.

These documents are crucial for future maintenance, troubleshooting, and warranty claims.

Never attempt to power the machine yourself unless you are trained and certified. Incorrect wiring can:

Damage the machine.

Void the warranty.

Cause serious injury.

Always adhere to safety protocols and consult professionals when dealing with electrical installations .

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.