Slovenia's manufacturing industry heavily relies on roll forming machines for producing various metal profiles used in construction, automotive, and industrial sectors. This article covers the most popular roll forming machines in the country, their specifications, applications, and how Machine Matcher can assist you in finding the right machine for your needs.

Types of Roll Forming Machines and Specifications

1. Roof Panel Roll Forming Machines

- Specifications:

- Roller Material: 45# steel with hard chrome plating

- Frame: H-beam or steel plate

- Motor: 5.5kW to 15kW

- PLC System: Siemens or Mitsubishi

- Speed: 10-15m/min

- Profiles Used: Trapezoidal, corrugated, and standing seam panels.

- Industries: Construction, roofing, and infrastructure projects.

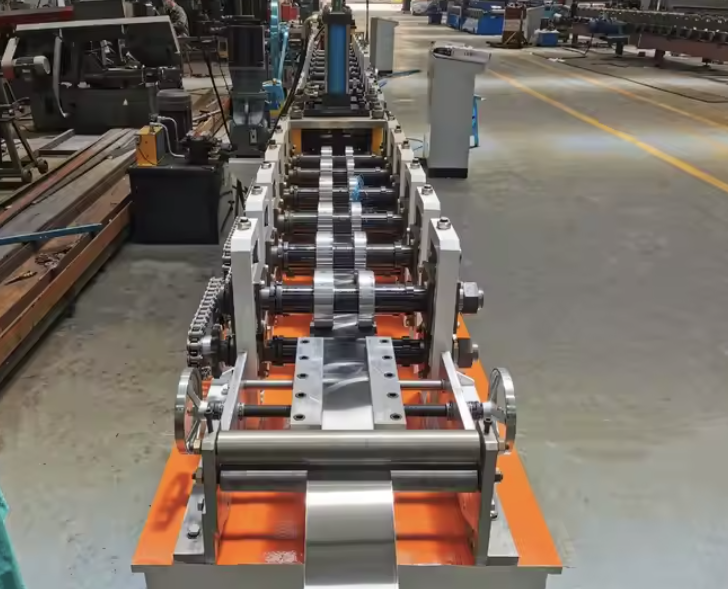

2. C Purlin Roll Forming Machines

- Specifications:

- Roller Material: GCr15 steel with heat treatment

- Frame: Steel welded structure

- Motor: 18.5kW

- PLC System: Panasonic

- Speed: 12-18m/min

- Profiles Used: C, Z, and U profiles.

- Industries: Industrial and commercial construction.

3. Highway Guardrail Roll Forming Machines

- Specifications:

- Roller Material: 45# Steel, heat-treated

- Frame: Heavy-duty H-beam

- Motor: 30kW

- PLC System: Delta

- Speed: 8-12m/min

- Profiles Used: W-beam and thrie-beam guardrails.

- Industries: Road safety infrastructure.

4. Decking Roll Forming Machines

- Specifications:

- Roller Material: D2 Steel

- Frame: Steel plate welded

- Motor: 22kW

- PLC System: Siemens

- Speed: 15-20m/min

- Profiles Used: Floor and roof deck profiles.

- Industries: High-rise buildings and commercial construction.

Main Cities and Areas Using Roll Forming Machines

The key regions in Slovenia utilizing roll forming machines include:

- Ljubljana: Central hub for construction and infrastructure projects.

- Maribor: Industrial manufacturing and steel production.

- Celje: Known for metal fabrication and machinery.

- Koper: A critical port city for imported steel materials.

- Novo Mesto: Automotive production and steel component manufacturing.

Maintenance of Roll Forming Machines

Regular maintenance ensures longevity and efficient operation. Key maintenance tasks include:

- Lubricating rollers and bearings.

- Checking hydraulic systems for leaks.

- Inspecting electrical connections and sensors.

- Cleaning and removing debris from the machine.

- Monitoring alignment of rollers and tooling.

Questions and Answers

Q: How often should a roll forming machine be serviced?

A: Depending on usage, a machine should be serviced every 500-1,000 hours.

Q: What materials are best suited for roll forming in Slovenia?

A: Galvanized steel, aluminum, and stainless steel are commonly used.

Q: How do I ensure the best machine for my profile needs?

A: Consulting with Machine Matcher ensures a tailored solution for your profile and production requirements.

Price Range of Roll Forming Machines Internationally

Roll forming machines can range from $50,000 to $500,000 depending on specifications, size, and customization.

Main Manufacturers in Slovenia

While Slovenia has limited domestic manufacturers, many businesses rely on imports from European and Chinese manufacturers. Prominent suppliers include:

- Dallan

- Formtek

- Samco Machinery

Setup and Operation of Roll Forming Machines

- Setup: Machines require a stable foundation and proper electrical supply.

- Operation: Operators input specifications into the PLC system for automated production.

- Safety Measures: Safety guards, emergency stops, and regular inspections are necessary.

How Machine Matcher Can Help You Buy the Best Roll Forming Machine

Machine Matcher simplifies the process of purchasing a roll forming machine. Our services include:

- Profile Matching: We find machines suited to your specific profiles.

- Inspection Services: Ensure quality before purchase.

- Price Negotiation: Get competitive prices.

- After-Sales Support: Receive assistance in installation and maintenance.

Contact Machine Matcher - Speak to one of our roll forming machine experts today:

- UK: +44 20 335 56554

- USA: +1 407 559 7948

- Europe: +32 460 24 13 95

- WhatsApp: +44 20 335 56554

- Email: [email protected]

Typical Applications of Roll Forming Machines

- Roofing and cladding sheets

- Steel framing

- Guardrails

- Solar panel mounting structures

- Metal storage racks

Troubleshooting Issues

- Misalignment: Check roller positioning and material feeding.

- Uneven Profiles: Inspect the tooling and calibrate.

- Electrical Malfunctions: Examine sensors and PLC connections.

Limitations of Roll Forming Machines

- Limited to producing long and continuous profiles.

- Requires significant floor space.

- Initial setup costs can be high.

Benefits of Roll Forming Machines

- High production efficiency.

- Consistent profile quality.

- Reduced material waste.

- Customization for various profiles.

Installation and Commissioning

- Preparation: Level the floor and ensure proper electrical connections.

- Assembly: Install machine parts and align rollers.

- Commissioning: Perform trial runs and adjust settings.

Operation and Maintenance

- Operators should be trained to manage PLC controls.

- Regularly inspect hydraulic and electrical systems.

- Maintain a clean working environment.

Design Standards

Roll forming machines adhere to international design standards like:

- ISO 9001 for quality management.

- CE certification for safety.

- ASTM standards for material specifications.

Machine Matcher is committed to helping you find the perfect roll forming machine for your production needs. Contact our experts today for a personalized consultation.