Posted on Thursday, June 15, 2023

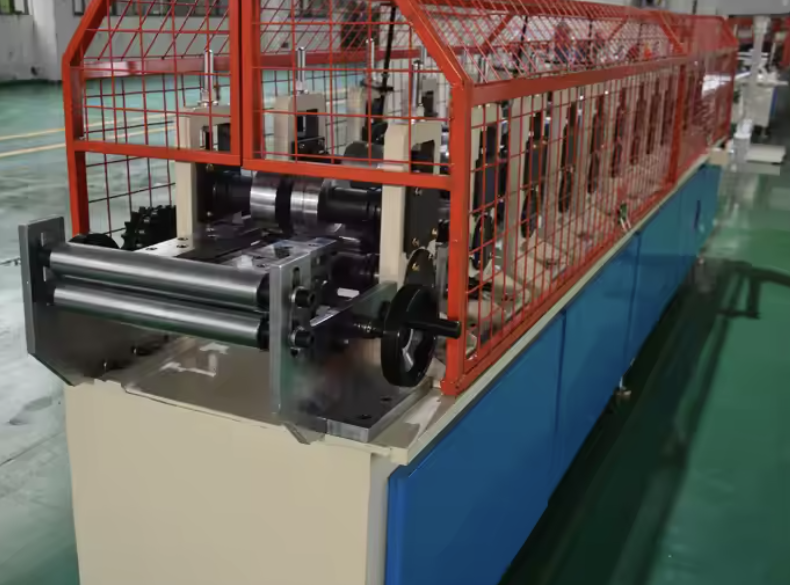

Zambia’s construction and manufacturing sectors have seen substantial growth in recent years, driven by increasing demand for infrastructure, housing, mining, and agriculture development. Roll forming machines are at the heart of many of these industries, producing essential steel profiles for roofing, structural framing, enclosures, and more. This article explores the most popular roll forming machines in Zambia, their specifications, the profiles they produce, industries that use them, and practical details like maintenance, cost, manufacturers, and setup. We’ll also cover why Machine Matcher is your best partner when sourcing roll forming machines for the Zambian market.

Specifications:

Roller Materials: GCr15 hardened steel with chrome coating

Machine Speed: 10–15 meters/min (standard) or 25–30 meters/min (high-speed models)

Frame: Welded steel frame with 16–20mm thickness

Cutting: Hydraulic shearing with Cr12 blades

PLC Control: Touchscreen interface (Siemens, Delta, or Schneider systems)

Power: 380V, 50Hz, 3-phase (adaptable to 220V or 415V if needed)

Used Profiles:

Corrugated roofing sheets

IBR (Inverted Box Rib) panels

Box profiles

Step tile metal roofing sheets

Industries Using These Machines:

Construction companies

Residential and commercial roofing manufacturers

Housing developers

Steel distribution outlets

Specifications:

Roller Stations: 14–20 stations depending on profile range

Material Thickness: 1.2mm to 3.0mm galvanized steel

Adjustable sizes: 80–300mm web width with auto/manual change

Punching System: Hydraulic punching for bolt holes and slots

Motor Power: 15kW–30kW

Used Profiles:

C and Z-shaped structural steel profiles

Optional Sigma profiles in some models

Industries Using These Machines:

Industrial steel building manufacturers

Warehouse constructors

Mining and agricultural storage facilities

Specifications:

Material: Color-coated steel, galvanized steel, aluminum

Forming Speed: 10–15 m/min

Hydraulic cutting system with servo motor synchronization

Optional decoiler and receiver table

Used Profiles:

Half-round gutters

K-style gutters

Rectangular or round downpipes

Industries Using These Machines:

Construction and roofing contractors

Rainwater system manufacturers

Building material suppliers

Specifications:

Material Thickness: 1.0mm–2.0mm cold-rolled steel

Servo feeding and hydraulic notching

Integrated punching, embossing, and cutting functions

Profile size: Custom sizes available

Used Profiles:

Steel door frames

Fire-rated and interior door profiles

Industries Using These Machines:

Steel door manufacturers

Commercial building contractors

Prefabricated structure manufacturers

Roll forming machines are commonly used in Zambia’s industrial and urban centers, where infrastructure development is most active:

Lusaka: The capital city and major industrial hub. Numerous construction firms, manufacturing plants, and steel depots operate here.

Ndola: Part of the Copperbelt Province and home to many mining companies and related industries that require purlins, cladding, and roofing panels.

Kitwe: Another major city in the Copperbelt with growing residential and commercial construction.

Chingola, Solwezi, and Livingstone: Secondary urban centers where regional construction and agricultural projects demand metal profiles.

Regular maintenance is essential to ensure long-term performance and avoid costly downtime. Key tasks include:

Daily:

Check for oil leaks and air pressure consistency

Clean the rollers and check alignment

Wipe down moving parts to prevent dust and debris buildup

Weekly:

Lubricate all moving components

Inspect hydraulic hoses and fittings

Tighten bolts and check chain tensions

Monthly:

Check motor and gearbox oil levels

Test PLC function and safety sensors

Perform roller adjustment tests with sample materials

Annually:

Replace hydraulic oil

Perform full inspection of electrical systems

Replace worn-out cutting blades or punching dies

The cost of roll forming machines in Zambia varies widely based on machine type, features, speed, and automation.

Low-End Machines (Manual Changeovers, Lower Speed):

Roofing Sheet Roll Forming Machine: $18,000 – $25,000

C Purlin Manual Model: $30,000 – $40,000

Gutter Machine: $15,000 – $20,000

High-End Machines (Automatic Changeover, Servo Systems, High Speed):

High-Speed IBR or Corrugated Roofing Line: $45,000 – $65,000

Fully Automatic C/Z Purlin Line: $60,000 – $90,000

Door Frame Line with Embossing and Servo Punching: $50,000 – $80,000

While Zambia does not manufacture roll forming machines domestically at scale, most machines are imported from manufacturers in:

China (Guangzhou, Botou, Wuxi-based suppliers)

India (Pune, Rajkot machine builders)

Turkey (High-end profile solutions)

South Africa (Some local distributors and resellers)

Local Zambian suppliers mainly act as importers, distributors, or service partners for machines built abroad.

Setup Process:

Foundation & Electrical Setup: Ensure the machine is installed on a level surface with the appropriate 3-phase power connection.

Material Loading: Load coils into the decoiler (manual or hydraulic) and feed through the straightener and guide rollers.

PLC Programming: Set up the cutting length, batch size, and punching positions on the PLC system.

Test Run: Perform a trial run with scrap material to check for alignment and profile accuracy.

Production: Begin continuous forming with material feeding, profiling, and cutting.

Operation Tips:

Always monitor the roller alignment and thickness of incoming coil

Ensure clean, dry, and rust-free materials for best results

Stop and realign rollers if slight deviations or wrinkling appear

At Machine Matcher, we specialize in connecting buyers across Africa—including Zambia—with the right roll forming machine that fits their exact profile, material, and production needs. Here’s why Zambian buyers trust us:

Wide Selection: We offer roofing, purlin, gutter, door frame, and specialty machines from reliable global manufacturers.

Profile Matching: You send us your drawing, dimensions, and requirements—we match you with the most suitable machine.

Technical Support: We guide you through setup, training, and maintenance—whether in-person or remote.

Transparent Pricing: Clear quotes and full machine specs so you know exactly what you’re getting.

Flexible Options: New, used, and refurbished machines available for different budgets.

Q1: Do I need a high-speed machine for roofing panels?

A: If you're producing panels for large projects or supplying dealers, yes. For smaller workshops, standard-speed machines (10–15m/min) may be sufficient.

Q2: Can I produce different profiles on one machine?

A: Some machines allow for profile changes, especially in purlin lines (C/Z adjustable). For roofing, each profile usually needs its own roller set or machine.

Q3: How long does delivery and installation take?

A: Delivery can take 6–10 weeks depending on the supplier. Installation usually takes 3–5 days with proper foundation and electrical setup.

Q4: What support do I get after buying?

A: Machine Matcher ensures you receive operation manuals, remote technical support, spare parts supply, and assistance with training your operators.

Q5: Is financing or part payment available?

A: We can help you connect with financing partners or staggered payment plans depending on the supplier.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Let Machine Matcher help you find the right roll forming machine for your business in Zambia. Whether you're producing roofing sheets in Lusaka, purlins in Ndola, or gutter systems in Kitwe, we’ve got you covered with machinery that fits your production goals and budget.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.