Posted on Thursday, August 24, 2023

Roll forming machines are widely used in Portugal across multiple industries, including construction, automotive, and renewable energy. These machines are capable of transforming metal sheets into customized profiles, ensuring consistency and accuracy in mass production. This blog explores the most popular roll forming machines in Portugal, highlighting their specifications, profiles, industries served, and regions where these machines are most commonly used. We will also discuss maintenance requirements, common issues, benefits, and international price ranges. Additionally, we will cover how Machine Matcher can assist buyers in Portugal with inspections and purchasing.

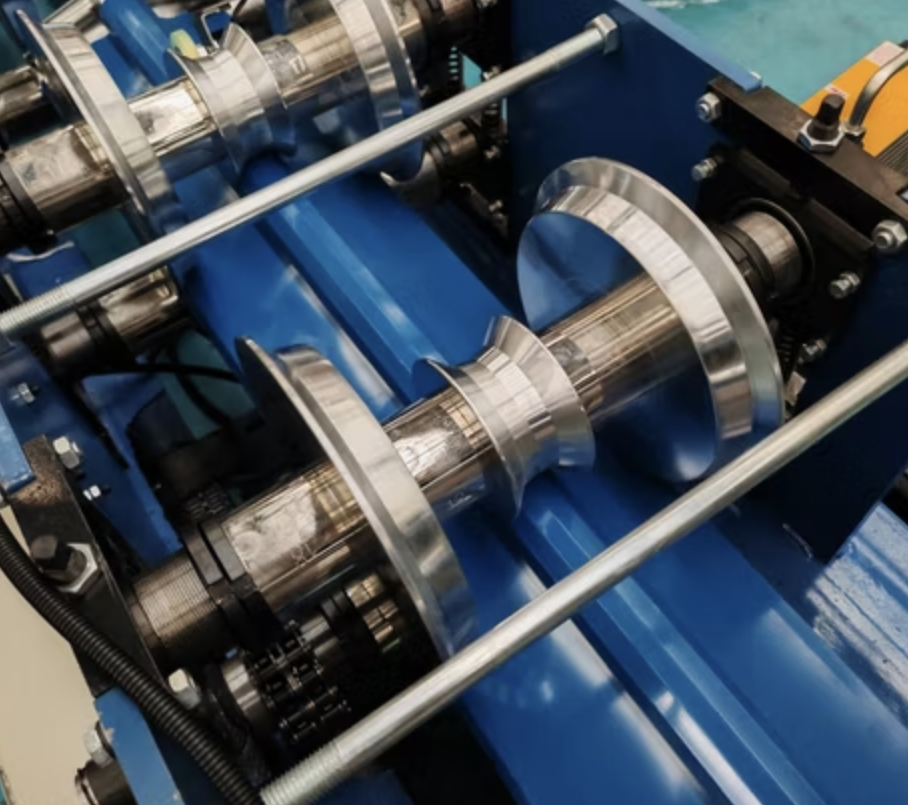

Specifications:

Roller Material: High-grade steel with chrome coating

Frame Size: 300-450 H-beam structure

Cutting System: Hydraulic cutting with post-cut mechanism

Motor Power: 7.5–15 kW depending on panel thickness

PLC System: Siemens or Mitsubishi for automated control

Machine Speed: 15–30 meters per minute

Profiles Used:

Trapezoidal panels

Corrugated roofing sheets

Standing seam panels

Industries Served:

Construction and roofing

Agricultural storage

Residential and commercial buildings

Specifications:

Roller Material: GCr15 with heat treatment

Frame: Steel plate welded with stress relief treatment

Punching and Notching: Hydraulic system with pre-punching and cutting

Motor Power: 11–22 kW depending on purlin thickness

PLC Control: Panasonic or Siemens with touch screen interface

Machine Speed: 10–20 meters per minute

Profiles Used:

C purlins

Z purlins

Industries Served:

Industrial buildings

Warehouses and hangars

Solar mounting systems

Specifications:

Roller Material: 45# steel with hard chrome plating

Frame: 400 H-beam welded frame

Hydraulic Cutting: Post-cut system with PLC synchronization

Motor Power: 18.5 kW for heavy-gauge profiles

PLC System: Delta or Siemens for automatic control

Machine Speed: 12–20 meters per minute

Profiles Used:

Metal decking panels

Composite floor decks

Industries Served:

High-rise buildings

Parking structures

Industrial flooring

Specifications:

Roller Material: Cr12 heat-treated rollers

Frame: 500 H-beam with reinforced structure

Hydraulic Punching and Cutting: CNC-controlled punching with high precision

Motor Power: 22–37 kW depending on thickness

PLC System: Omron or Siemens for advanced automation

Machine Speed: 10–15 meters per minute

Profiles Used:

W-beam guardrails

Thrie-beam guardrails

Industries Served:

Road infrastructure

Safety barrier manufacturing

Specifications:

Roller Material: GCr15 with precision grinding

Frame: 350 H-beam structure for stability

Motor Power: 7.5–15 kW based on profile dimensions

PLC System: Mitsubishi with remote PLC control

Machine Speed: 12–25 meters per minute

Profiles Used:

Half-round gutters

K-style gutters

Downspouts

Industries Served:

Rainwater management

Residential and commercial buildings

Lisbon: Industrial hubs focusing on construction and metalworking industries

Porto: Significant demand for roofing and purlin systems for commercial buildings

Setúbal: Focus on shipbuilding and automotive components

Braga and Coimbra: Emerging regions for metal fabrication and sheet metal industries

Aveiro: Specialized in solar mounting structures and metal profiles

Lubrication: Regularly lubricate rollers, bearings, and drive chains to prevent wear.

Roller Inspection: Check for any deformation, cracks, or corrosion in the rollers.

Hydraulic System: Maintain hydraulic oil levels and inspect for leaks.

PLC System Calibration: Periodically update and calibrate the PLC system to ensure smooth operation.

Blade and Cutting System: Sharpen and replace blades to maintain clean and precise cuts.

Construction Industry: Roofing panels, floor decks, and cladding profiles

Automotive Sector: Structural profiles, door frames, and side panels

Renewable Energy: Solar panel mounting structures and purlins

Transportation Infrastructure: Guardrails and safety barriers

Industrial Warehouses: Purlins and decking systems

Misaligned Rollers: Adjust roller settings to prevent profile deformation.

Hydraulic Failure: Inspect the hydraulic system for leaks and check for low oil pressure.

PLC Errors: Reboot or reconfigure the PLC to restore functionality.

Material Jamming: Check the feeding system and adjust coil tension.

Cutting Inaccuracy: Calibrate the cutting blades and ensure proper alignment.

Material Thickness Limitations: Machines are designed for specific thickness ranges, exceeding which may damage rollers.

Profile Design Constraints: Complex profiles may require additional tooling and customized roller sets.

High Initial Investment: Advanced roll forming machines can be expensive, requiring careful planning.

Space Requirements: Machines require adequate space for coil loading, forming, and cutting operations.

High Production Efficiency: Consistent profiles with minimal wastage.

Customization Flexibility: Ability to create diverse profiles using different roller sets.

Cost-Effectiveness: Reduced labor costs and minimal raw material waste.

Precision and Accuracy: Uniform profiles with minimal dimensional variations.

Site Preparation: Ensure adequate space, foundation, and power supply.

Machine Assembly: Connect all mechanical, hydraulic, and electrical systems.

Testing and Calibration: Run trial operations to calibrate roller settings and PLC parameters.

Operator Training: Provide hands-on training for operators and maintenance teams.

Final Inspection: Ensure all safety features and controls are functioning properly.

Daily Checks: Inspect lubrication systems, roller alignment, and cutting mechanisms.

Periodic Maintenance: Clean and replace worn-out parts such as blades and rollers.

Hydraulic System Service: Check for oil levels, filter changes, and pressure settings.

PLC System Updates: Upgrade firmware and recalibrate for consistent operation.

ISO 9001: Quality management standards for manufacturing consistency.

CE Certification: Compliance with European safety and environmental regulations.

EN 1090: Standards for structural steel and aluminum components.

ANSI Standards: Compliance with American safety and performance standards.

Roof Panel Roll Forming Machines: $25,000–$80,000

C/Z Purlin Roll Forming Machines: $40,000–$120,000

Deck Roll Forming Machines: $50,000–$150,000

Guardrail Roll Forming Machines: $70,000–$200,000

Gutter and Downspout Machines: $20,000–$70,000

Joris Ide Group: Leading provider of roll forming equipment and steel profiles.

Perfilgroup: Specializes in customized roll forming machines for various industries.

Ferpinta: Supplier of structural profiles and metal sheets used in roll forming.

Machine Matcher is an industry leader that connects buyers with the most suitable roll forming machines worldwide. Our platform provides a streamlined process for inspecting, selecting, and purchasing machines tailored to your production requirements. We offer:

Pre-Purchase Inspections: Ensuring machine quality and condition before purchase.

Profile Compatibility Matching: Matching machines to your desired profiles and materials.

Logistical Support: Coordinating shipping and installation for buyers in Portugal.

Expert Consultation: Professional guidance to choose the right machine for your industry.

Inspection Services:

Machine Matcher offers pre-purchase inspections to assess the condition, functionality, and performance of roll forming machines. Our experts verify roller alignment, PLC system integrity, and hydraulic performance to ensure the machine meets industry standards.

Profile Compatibility Analysis:

We analyze your desired profiles and recommend machines that align with your production requirements. Whether you need roofing panels, purlins, or guardrails, Machine Matcher ensures a perfect match.

Logistical Coordination:

We assist with arranging shipping, delivery, and on-site installation of the machines. Our team ensures compliance with Portugal’s safety and quality standards during commissioning.

After-Sales Support:

Machine Matcher provides ongoing support, operator training, and maintenance guidelines to ensure smooth operation after installation.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.