Posted on Wednesday, November 15, 2023

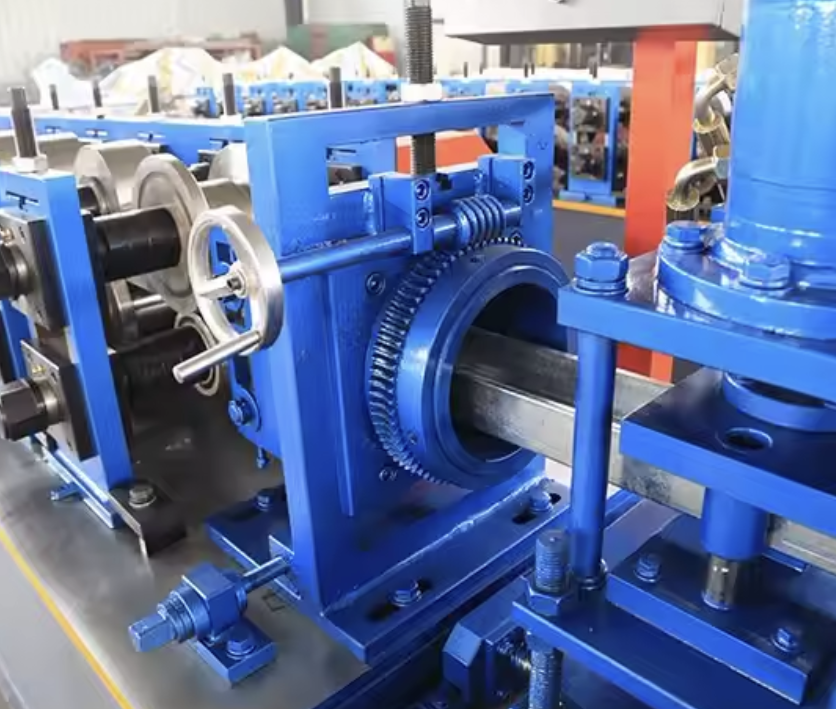

Roll forming machines play a significant role in Kyrgyzstan's construction, roofing, and infrastructure industries. These machines produce a wide variety of profiles, meeting the growing demand for quality metal structures in the region. This guide explores the most popular roll forming machines used in Kyrgyzstan, highlighting machine types, specifications, profiles, industries, pricing, manufacturers, and how to maintain and operate these machines. Additionally, this article will discuss troubleshooting, design standards, and the benefits of using roll forming machines, while also detailing how Machine Matcher can assist in finding the best machine to meet your profile requirements.

Specifications:

Roller Material: High-grade GCr15 steel with heat treatment

Frame Structure: Welded steel frame for high strength

PLC System: Fully automated control with touch-screen interface

Cutting Mechanism: Hydraulic cutting with automatic length control

Speed: 12-15 m/min (standard) or 30-40 m/min (high-speed versions)

Power Supply: 380V, 50Hz, 3-phase (adjustable to Kyrgyzstan's power requirements)

Popular Profiles:

Corrugated roofing sheets

Trapezoidal roofing sheets

Standing seam panels

Specifications:

Roller Material: Hardened steel rollers with chrome plating

Frame: Heavy-duty steel structure with bolted components

Motor Power: 7.5 kW to 15 kW depending on capacity

Punching System: Hydraulic punching with pre-cut or post-cut options

Speed: 10-15 m/min

Popular Profiles:

C and Z purlins in various sizes (typically 80 mm to 300 mm width)

Purlins for structural steel framing and roof trusses

Specifications:

Roller Material: Alloy steel with heat treatment for durability

Motor Power: 15 kW to 25 kW

Punching and Notching: Hydraulic punching for holes and slots

Cutting System: Hydraulic cutter with precision controls

Popular Profiles:

W-beam and thrie-beam guardrails for road safety

Crash barrier profiles

Specifications:

Roller Material: Heat-treated GCr15 steel

Frame: Heavy-duty welded frame with stability reinforcements

PLC System: Mitsubishi or Siemens control systems

Speed: 10-20 m/min

Popular Profiles:

Steel deck panels for commercial buildings and industrial floors

Specifications:

Roller Material: Hardened steel rollers with chrome coating

Punching System: Servo-driven punching for high accuracy

Cutting: Hydraulic post-cutting system

Speed: 15-25 m/min

Popular Profiles:

Light gauge steel framing for residential and commercial buildings

Construction Industry: Roofing, purlins, steel framing, and structural components.

Infrastructure Development: Guardrails and road safety barriers.

Commercial and Industrial Buildings: Steel decking and cladding panels.

Agricultural Sector: Greenhouse structures and fencing.

Transportation: Manufacturing of vehicle bodies and trailers.

Bishkek: Largest market for construction and infrastructure projects.

Osh: Developing city with increasing demand for metal profiles.

Jalal-Abad: Emerging market for light gauge steel framing.

Karakol and Tokmok: Small but growing regions utilizing roll forming technologies for agricultural and industrial applications.

Clean and lubricate the rollers and moving parts.

Check the alignment of rollers and cutting blades.

Inspect the hydraulic system for leaks.

Tighten all bolts and fasteners.

Check the PLC system and sensors for proper operation.

Grease bearings and inspect electrical connections.

Replace worn-out rollers or hydraulic seals.

Perform a complete inspection of motors and gearboxes.

Roofing Roll Forming Machines: $20,000 to $50,000

C/Z Purlin Roll Forming Machines: $40,000 to $80,000

Highway Guardrail Roll Forming Machines: $60,000 to $120,000

Decking Roll Forming Machines: $50,000 to $90,000

LGSF Roll Forming Machines: $70,000 to $150,000

Local Manufacturers: Limited local manufacturing; most machines are imported.

Popular Suppliers:

China: Known for cost-effective machines with advanced features.

Turkey: High-quality machines with European standards.

India: Budget-friendly options with reliable performance.

Foundation and Alignment: Install the machine on a level surface and align it correctly.

Power Connection: Connect the machine to a stable 380V, 50Hz power supply.

Hydraulic System: Fill the hydraulic tank and check for leaks.

Roller Calibration: Adjust rollers for the desired profile.

Load Material: Place the steel coil in the uncoiler.

Adjust Settings: Configure PLC settings for profile length and cutting options.

Start Machine: Run a test cycle to ensure proper operation.

Monitor Production: Ensure continuous monitoring to maintain quality.

Roofing and wall cladding

Structural components for buildings

Guardrails and crash barriers

Light gauge steel framing

Steel decking for commercial structures

Misalignment of Rollers: Adjust rollers to ensure uniform profile shaping.

Inconsistent Cutting Length: Check PLC settings and hydraulic cutter calibration.

Hydraulic Leaks: Inspect hoses and seals for wear and replace if needed.

Material Jamming: Clean rollers and remove any debris.

Limited to continuous profile production

High initial investment for advanced machines

Requires skilled operators for precision adjustments

Material limitations based on gauge and strength

High production efficiency and consistency

Reduced material waste compared to other processes

Ability to create complex profiles with precision

Low labor costs and minimal manual intervention

Machine Positioning and Leveling: Ensure a stable base to prevent vibrations.

Power and Hydraulic System Connection: Verify voltage compatibility.

Test Run and Calibration: Adjust roller settings and ensure smooth operation.

Operator Training: Provide training on machine usage, maintenance, and safety.

Routine Inspections: Regularly inspect for wear and tear.

Lubrication Schedule: Apply lubricants as per manufacturer recommendations.

Safety Checks: Ensure safety guards and emergency stop mechanisms are functional.

ISO 9001: Ensures quality management in machine production.

CE Certification: Compliance with European safety and performance standards.

ASTM Standards: Applicable for specific profile and material requirements.

Machine Matcher provides expert guidance to help buyers in Kyrgyzstan select the right roll forming machine based on their unique profile needs. Whether you require machines for roofing, purlins, guardrails, or other applications, Machine Matcher connects you with reliable manufacturers globally and ensures quality assurance during the purchasing process.

Profile Matching: Ensure the machine matches your required profile specifications.

Supplier Verification: Connect with trusted manufacturers and verify machine quality.

Inspection and Testing: Conduct quality inspections before delivery.

After-Sales Support: Provide guidance on setup, operation, and troubleshooting.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.