Posted on Wednesday, December 13, 2023

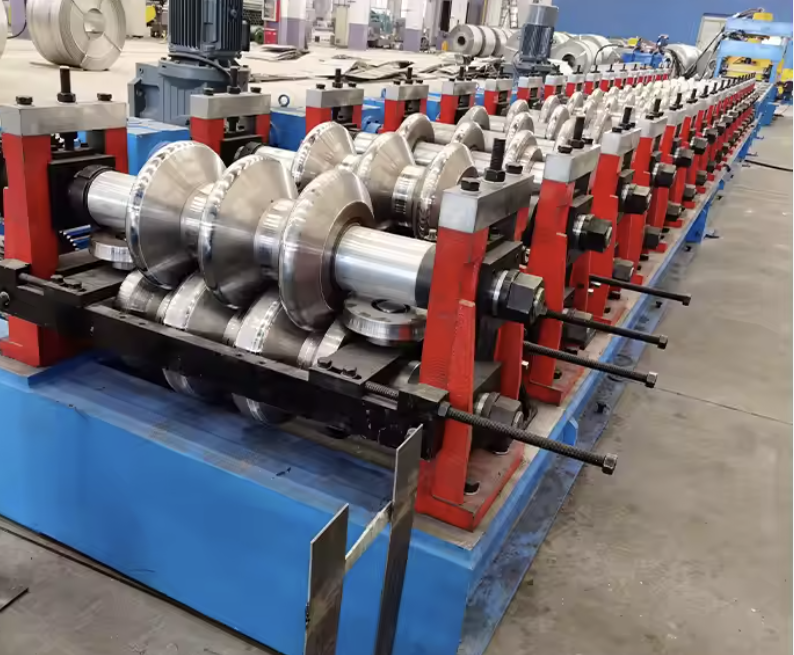

Cabo Verde, an archipelago off the west coast of Africa, is gradually becoming an important market for steel construction and light manufacturing. As the construction, roofing, and metal fabrication sectors grow across Santiago, São Vicente, and other key islands, demand for efficient, reliable roll forming machines has increased. These machines allow companies to produce high-quality metal profiles at scale, whether for roofing panels, structural components, or building trims.

In this guide, we explore the most popular types of roll forming machines in Cabo Verde, their specifications, the industries that rely on them, where they are used, and how to maintain and operate them effectively. We also include a pricing overview, top manufacturers, and why Machine Matcher is the ideal partner to help you choose the right machine for your profile and production goals.

Specifications:

Profile types: Corrugated, trapezoidal, AG panels

Material: Galvanized steel, aluminum, color-coated steel

Roller stations: 14–18

Material thickness: 0.3–0.8 mm

Motor power: 4–7.5 kW

Speed: 10–15 m/min

Industries: Roofing, commercial and residential construction, coastal housing developments.

Specifications:

Profile types: C100–C300, Z120–Z300

Material thickness: 1.5–3.0 mm

Hydraulic cutting system

Punching unit for holes and slots

Fully automatic PLC control

Industries: Warehousing, agriculture buildings, factories, solar panel structures.

Specifications:

Profile types: Semi-round, angular ridge cap

Material: Pre-painted galvanized steel

Thickness: 0.3–0.6 mm

Motor: 3 kW

Production speed: 10–12 m/min

Industries: Roofing accessories manufacturing, rural and coastal roofing supply.

Specifications:

Profiles: 50, 75, 100 mm stud & track

Thickness: 0.5–1.2 mm

Roller material: GCr15 steel

Quick-change cassettes

Servo feeding and punching

Industries: Interior partitioning, hotels, office builds, prefab structures.

Specifications:

Profiles: K-style, half-round gutter

Thickness: 0.4–0.7 mm

Motor: 4 kW

Control: Touch screen PLC with automatic length cutting

Industries: Rainwater management, building restoration, property development.

Construction – Most machines are used to fabricate building components such as roofing sheets, gutters, and structural profiles.

Agricultural Infrastructure – Farms, storage barns, and greenhouses rely on C and Z purlin and sheet roofing.

Tourism Infrastructure – Hotels, guesthouses, and resorts under development use modern metal roofing and paneling.

Public Works – Municipal buildings and coastal shelters often incorporate metal fabricated components.

Praia (Santiago) – The capital and largest economic hub, with high demand for roofing and cladding.

Mindelo (São Vicente) – A commercial center with port development and tourism-driven construction.

Santa Maria (Sal) – Growing resort construction industry.

Espargos – Logistic and warehouse developments.

Assomada and São Filipe – Smaller regions with agricultural and rural construction demand.

Regular maintenance ensures long life and consistent performance. In Cabo Verde’s humid coastal climate, preventative care is especially important.

Lubricate moving parts and bearings

Check for metal shavings around the rollers

Clean and inspect forming rollers

Inspect hydraulic systems for leaks or pressure drops

Examine chains and belts for wear

Tighten all electrical connections

Replace hydraulic oil and filters

Calibrate roller stations

Software and PLC system updates

Preventive maintenance should be documented, and machine operators trained on best practices to reduce downtime.

Machine Positioning – Install the machine on a flat concrete surface, preferably indoors.

Power Connection – Ensure correct voltage; Cabo Verde typically uses 220V/380V three-phase.

Material Loading – Use a manual or hydraulic uncoiler to load the steel coil.

Profile Calibration – Adjust the rollers and cutters to match the desired profile.

Software Input – Set length, batch quantity, and punching positions via the PLC.

Start the system through the control panel.

Feed material through guide rollers.

Monitor for alignment and profile accuracy.

Finished profiles are automatically cut and collected.

Operators should wear proper PPE and be trained on emergency stop procedures and material handling.

Prices vary based on machine complexity, automation level, and build quality.

| Machine Type | Low-End Price (USD) | High-End Price (USD) |

|---|---|---|

| Roof Panel Machine | $18,000 | $55,000 |

| C/Z Purlin Machine | $30,000 | $95,000 |

| Ridge Cap Machine | $10,000 | $30,000 |

| Stud & Track Machine | $25,000 | $60,000 |

| Gutter Machine | $12,000 | $40,000 |

Custom tooling, servo systems, and automation features add to the price.

Cabo Verde does not yet manufacture roll forming machines locally. Most machines are imported from:

Turkey

China

India

Europe (Germany, Italy)

Well-known international brands are available via global suppliers or partners like Machine Matcher, which connects buyers to the right manufacturer based on profile and budget.

Machine Matcher specializes in connecting buyers in developing and growing markets with high-quality new and used roll forming machines that match their profile needs, budget, and local conditions.

We understand the climate, voltage requirements, and profile preferences in Cabo Verde.

We offer multilingual support and region-specific expertise.

We help reduce shipping costs by matching you with the nearest manufacturers.

Access to both new and used machines, verified for quality and condition.

Custom solutions for profiles specific to Cabo Verde’s roofing and structural standards.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

A: Basic operator training is essential. For advanced machines with PLC systems, skilled technicians are recommended.

A: Delivery typically takes 30–60 days depending on the country of origin and shipping arrangements.

A: Yes. Used machines are a great option for startups or smaller operations. Machine Matcher can help source and inspect them.

A: Corrugated roofing panels, trapezoidal sheets, C/Z purlins, ridge caps, and stud & track profiles are commonly used.

A: Absolutely. Machines can be configured to match custom profiles, material gauges, and cutting lengths.

If you're planning to expand your metal fabrication or construction capacity in Cabo Verde, investing in the right roll forming machine is essential. Whether you're in Praia or Mindelo, Machine Matcher can help you select the right equipment, guide you through setup, and support your production journey.

Let us help you make the right investment — reach out to Machine Matcher today.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.