Posted on Saturday, December 16, 2023

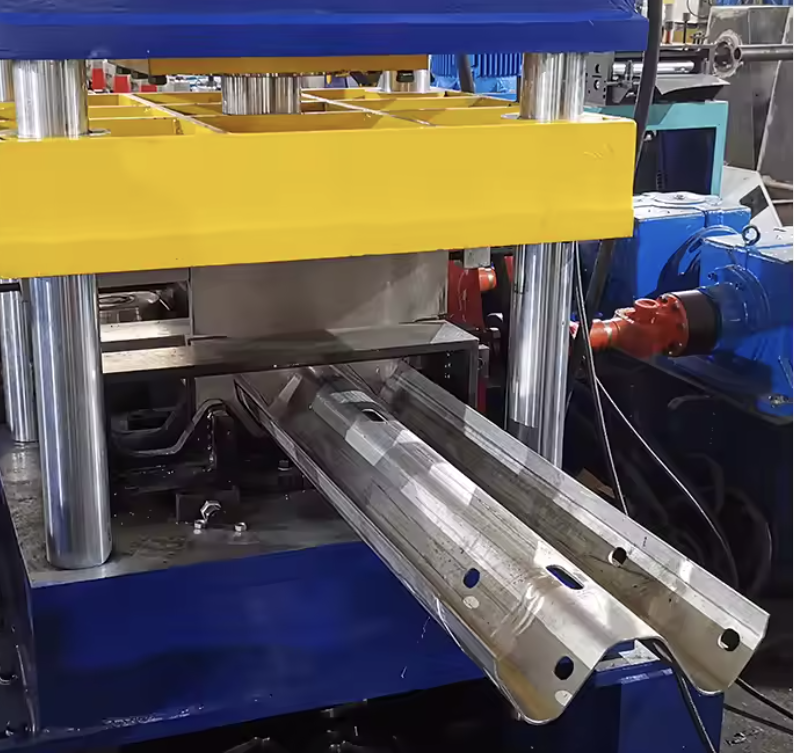

Côte d'Ivoire, one of West Africa’s fastest-growing economies, is seeing steady growth in infrastructure, industrial construction, and agricultural development. This expansion is fueling demand for metal products such as roofing sheets, wall panels, steel framing components, cable trays, and more. Roll forming machines have become essential tools for manufacturers and contractors across the country looking to produce high-quality metal profiles efficiently and cost-effectively.

In this article, we will explore the most popular types of roll forming machines used in Côte d'Ivoire, including their specifications, the profiles they produce, the industries that use them, the regions where they are most in demand, and much more. Whether you are starting a new metal fabrication business or expanding an existing one, this guide will help you make informed decisions.

Common Profiles: IBR, corrugated, trapezoidal, and step tiles

Specifications:

Rollers: GCr15 steel with hard chrome plating

Frame: 16–20mm thick steel plate or H-beam frame

Power: 5.5–15 kW main motor, 4 kW hydraulic cutting motor

Cutting: Hydraulic cutting with encoder control

Speed: 10–15 meters per minute

Control: PLC control system with HMI touch screen

Industries Using This Machine:

Residential and commercial roofing

Infrastructure and public buildings

Warehousing and logistics

Common Profiles: C100–C300, Z120–Z300 with adjustable sizes

Specifications:

Roller stations: 16–22 stations

Frame: H-beam or steel plate frame

Drive system: Gearbox or chain

Changeover: Manual or automatic size change system

Speed: 10–20 meters per minute

Cutting: Hydraulic with servo positioning

Industries Using This Machine:

Steel structure construction

Agricultural buildings

Warehousing

Common Profiles: Floor decking with embossing and ribs

Specifications:

Thickness: 0.8–1.5 mm galvanized steel

Frame: Welded steel structure

Cutting: Hydraulic with PLC control

Speed: 8–15 meters per minute

Embossing: Integrated with forming rollers

Industries Using This Machine:

Multi-story buildings

Office complexes

Industrial plants

Common Profiles: Ladder and perforated cable trays, widths from 50–600 mm

Specifications:

Punching: Hydraulic or mechanical inline punching

Thickness: 0.6–2.0 mm

Speed: 10–25 meters per minute

Control: PLC with automatic sizing (for some models)

Industries Using This Machine:

Electrical and telecom infrastructure

Manufacturing facilities

Industrial installations

The demand for roll forming machines is highest in urban and industrial centers such as:

Abidjan – The capital and commercial hub; home to most metal fabrication factories, warehouses, and construction companies.

Bouaké – A growing industrial and transportation center in central Côte d'Ivoire.

San Pedro – Major port city and industrial zone with rising demand for roofing and cladding products.

Yamoussoukro – The political capital with infrastructure and public projects requiring structural metal components.

Korhogo – Northern region city with growing agricultural and storage facility construction.

To keep roll forming machines running efficiently in Côte d'Ivoire’s tropical and humid environment, regular maintenance is essential. Key tasks include:

Daily Cleaning: Remove dust, debris, and metal scraps after each shift.

Lubrication: Apply oil or grease to bearings, chains, and moving parts weekly.

Roller Inspection: Check rollers for wear or misalignment monthly.

Hydraulic System Check: Monitor oil levels and inspect hoses every two weeks.

Electrical System Testing: Check sensors, encoders, PLC, and wiring monthly.

Blade Sharpening: Hydraulic or flying cutoff blades may require sharpening or replacement every 3–6 months, depending on usage.

Preventive maintenance not only extends machine life but also ensures product accuracy and reduces downtime.

Machine pricing depends on machine complexity, configuration, and included automation systems.

| Machine Type | Low Cost (USD) | High Cost (USD) |

|---|---|---|

| Roofing Roll Forming Machine | $18,000 | $45,000 |

| C/Z Purlin Machine | $28,000 | $65,000 |

| Floor Deck Machine | $30,000 | $70,000 |

| Cable Tray Machine | $35,000 | $80,000 |

Prices vary based on automation features (manual vs automatic changeover), cutting systems (mechanical vs hydraulic vs flying cutoff), and extras like stackers, uncoilers, and punching units.

While Côte d'Ivoire does not have many local manufacturers of roll forming machines, most machines are imported from China, Turkey, India, and Europe. Buyers often import through:

Local dealers in Abidjan

Construction equipment suppliers

Direct import via global platforms

Working with an expert partner like Machine Matcher ensures the machine is matched to your profile and business needs, whether you're in roofing, cable tray manufacturing, or structural steel.

Setup Includes:

Leveling and bolting the machine to the factory floor

Connecting the power supply (usually 380V/50Hz or customized)

Installing uncoilers and hydraulic systems

Calibrating rollers to the desired profile size

Programming the PLC for batch quantity, length, and profile type

Operation Steps:

Load coil on uncoiler

Thread material through rollers

Start the PLC-controlled system

Monitor profile output and make adjustments if needed

Collect finished profiles manually or with auto stackers

Training is usually provided with the machine to help operators run it safely and efficiently.

Machine Matcher offers a global network of roll forming machine manufacturers, suppliers, and service technicians. We help you choose the best machine for your business based on:

Profile drawing and size

Required material thickness

Speed and output capacity

Voltage and power supply in Côte d'Ivoire

Optional features like punching, stackers, or remote PLC access

Our team ensures your machine arrives ready to work, and we provide full support with shipping, installation, and after-sales service.

Q1: Can I use a roll forming machine outdoors in Côte d'Ivoire?

A1: Machines should be installed in a covered workshop or factory to avoid moisture damage and rust from the humid coastal climate.

Q2: What profiles are most in demand in Côte d'Ivoire?

A2: IBR roofing, corrugated sheets, step tiles, C/Z purlins, and perforated cable trays are commonly used in construction and industrial sectors.

Q3: Do I need a skilled operator to run the machine?

A3: Basic technical skills are required, but most machines come with user-friendly PLC systems. Machine Matcher can also help arrange training.

Q4: How long does it take to install a roll forming machine?

A4: Installation typically takes 2–4 days depending on the machine type and factory setup.

Q5: Can I customize the profile shape?

A5: Yes, we can match machines to your custom profile drawing or recommend standard profiles based on local market demand.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Let us help you find the right roll forming machine tailored to your profile, budget, and production goals in Côte d'Ivoire.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.