Posted on Wednesday, December 20, 2023

Roll forming machines have become an essential component in Ireland's growing construction, manufacturing, and steel industries. With increased demand for high-quality profiles in sectors like roofing, cladding, and structural components, roll forming machines offer efficiency, precision, and scalability. This blog explores the most popular roll forming machines used in Ireland, highlighting their types, specifications, profiles produced, industries that rely on them, and the key cities and regions where they are predominantly used. We will also delve into maintenance requirements, troubleshooting, benefits, and potential limitations while emphasizing how Machine Matcher can assist buyers in making informed purchasing decisions.

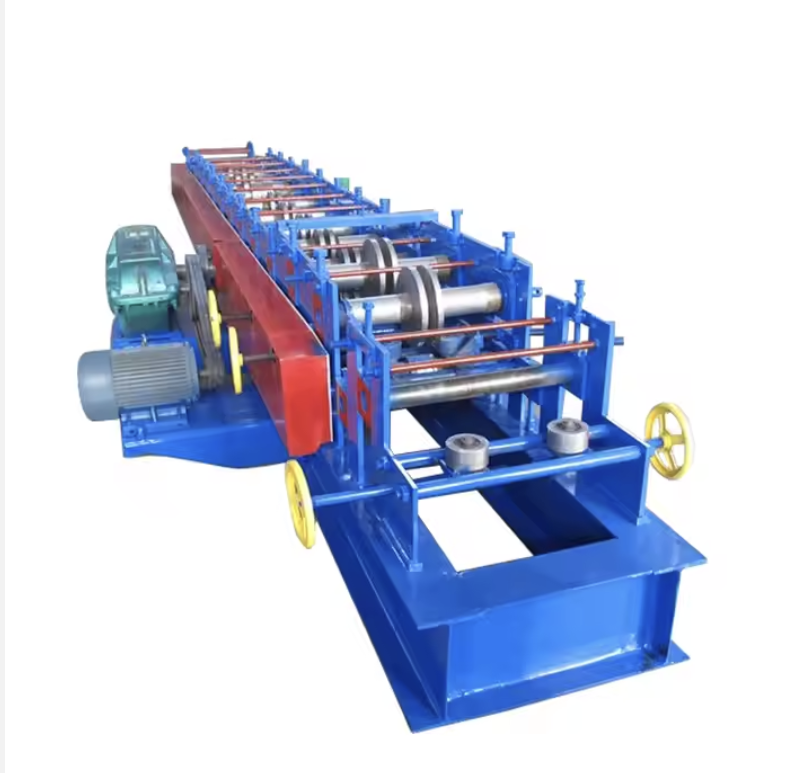

Specifications:

Roller Materials: GCr15 steel with heat treatment

Frame Size: 300–450 mm H-beam structure

Drive System: Chain or gearbox drive

Cutting System: Hydraulic post-cutting system

PLC Control: Fully automatic with touch screen

Machine Speed: 15–30 m/min

Safety Guards: Standard enclosures with emergency stop system

Profiles Produced:

Corrugated roofing sheets

Trapezoidal metal panels

Standing seam roof panels

Industries:

Construction and roofing

Residential, commercial, and industrial projects

Main Cities and Areas:

Dublin, Cork, Limerick, Galway, and Waterford

Specifications:

Roller Materials: High-grade steel with chrome coating

Frame Size: 350–550 mm H-beam

Drive System: Hydraulic and servo motor systems

Cutting System: Pre-punching and post-cutting

PLC Control: Integrated with hydraulic punching

Machine Speed: 10–20 m/min

Optional Add-ons: Automatic stacker and coil handling systems

Profiles Produced:

C and Z purlins

Hat and U channels

Industries:

Structural and industrial construction

Agricultural buildings and steel warehouses

Main Cities and Areas:

Belfast, Galway, Drogheda, and Sligo

Specifications:

Roller Materials: GCr15 with CNC machining

Frame Size: Heavy-duty steel frame

Drive System: Hydraulic and gearbox systems

Cutting System: Hydraulic flying cut

PLC Control: Automatic with fault diagnosis system

Machine Speed: 20–40 m/min

Safety Features: Emergency stop, safety sensors

Profiles Produced:

Steel floor decking panels

Composite floor panels

Industries:

Commercial and residential buildings

Industrial construction projects

Main Cities and Areas:

Dublin, Cork, Shannon, and Limerick

Specifications:

Roller Materials: Hardened steel rollers

Frame Size: 300–450 mm steel frame

Drive System: Gearbox and chain drive

Cutting System: Hydraulic with post-cut

PLC Control: Touchscreen interface

Machine Speed: 10–25 m/min

Additional Features: Automatic stackers and uncoilers

Profiles Produced:

Half-round gutters

K-style and box gutters

Industries:

Roofing and drainage systems

Residential and commercial buildings

Main Cities and Areas:

Waterford, Limerick, and Cork

Roofing and Cladding Panels: Used extensively in residential, commercial, and industrial buildings.

Structural Components: Purlins and decking for steel-framed buildings and industrial projects.

Drainage Systems: Gutters and downspouts for efficient water management.

Agricultural Structures: Panels and profiles for barns, storage facilities, and livestock housing.

Clean the rollers and remove debris.

Lubricate bearings, chains, and moving parts.

Inspect hydraulic systems for leaks or wear.

Check for misalignment and adjust roller settings.

Examine the electrical system and replace faulty wiring.

Inspect cutting blades and replace if necessary.

Full inspection of the machine frame and control system.

Recalibration of the PLC and checking for software updates.

Complete hydraulic system flushing and oil replacement.

Misalignment of Profiles

Cause: Improper roller adjustment or wear.

Solution: Realign rollers and check calibration.

Uneven Cutting or Burrs

Cause: Dull cutting blades or incorrect clearance.

Solution: Replace cutting blades and adjust settings.

PLC or Electrical Failures

Cause: Loose connections or software errors.

Solution: Tighten connections and reset the system.

Profile Limitations: Machines are typically designed for specific profiles and cannot easily switch between different designs.

Space Requirements: Large machines require adequate factory space.

Initial Investment: High upfront costs for advanced roll forming machines.

High Efficiency: Continuous production with minimal waste.

Custom Profiles: Flexibility to design and produce various profiles.

Reduced Labor Costs: Automation reduces the need for manual labor.

Consistent Quality: Precision and accuracy in profile production.

Site Preparation: Ensure adequate space and a leveled surface.

Machine Assembly: Position and secure components as per manufacturer guidelines.

Power and Hydraulic Setup: Connect electrical and hydraulic systems.

Software Configuration: Load and test PLC programs for profile calibration.

Trial Run and Calibration: Perform initial test runs to ensure smooth operations.

Training and Handover: Train operators on machine operation and safety protocols.

Startup Procedures: Ensure the machine is properly lubricated and calibrated before initiating operations.

Routine Monitoring: Regularly monitor machine speed, cutting accuracy, and product quality.

Shutdown Procedures: Turn off the machine properly, clean the rollers, and secure the system.

EN 1090 Compliance: Adherence to structural steel fabrication standards.

ISO 9001 Certification: Quality management and continuous improvement.

CE Certification: Compliance with European safety regulations.

BS EN 10162 Standards: Cold-rolled steel profiles standard adherence.

Basic Roofing Panel Machines: $20,000 – $50,000

Purlin Roll Forming Machines: $50,000 – $100,000

Decking Roll Forming Machines: $80,000 – $150,000

Gutter Roll Forming Machines: $30,000 – $60,000

Dallan S.p.A. – Offers high-precision roll forming lines with a focus on sheet metal processing.

Formtek Group – Provides advanced roll forming solutions with integrated automation.

Gasparini Industries – Known for high-performance roll forming equipment.

Jupiter Rollforming Pvt. Ltd. – Specializes in customized roll forming machinery.

Machine Matcher is your trusted partner in identifying the right roll forming machine for your specific profile needs. Our platform offers a wide range of new and used roll forming machines from verified manufacturers worldwide. With our expertise in matching buyers with the best machines, we ensure that you receive top-notch support from inspection to commissioning.

Machine Inspection: Comprehensive inspection of used machines to ensure operational efficiency.

Profile Matching: Analysis of your required profiles to match you with the most suitable machine.

Logistics and Delivery: Assistance with shipping, import duties, and customs clearance.

After-Sales Support: Ongoing technical support and maintenance assistance.

Expert Consultation: Professional advice on choosing between new and used machines.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Machine Matcher ensures that buyers in Ireland receive expert guidance and high-quality roll forming machines that meet their production needs.

Q1: How do I choose the right roll forming machine for my business?

A1: Consider the profile type, material thickness, production volume, and available factory space before making a decision.

Q2: What is the expected lifespan of a roll forming machine?

A2: With proper maintenance, roll forming machines can last 15–20 years.

Q3: Are used roll forming machines a reliable investment?

A3: Yes, if properly inspected and maintained, used machines can deliver excellent performance at a lower cost.

Q4: How long does it take to install and commission a roll forming machine?

A4: Installation and commissioning can take 2–4 weeks depending on machine complexity and site conditions.

Q5: How can Machine Matcher assist with after-sales support?

A5: We provide technical guidance, troubleshooting, and maintenance assistance post-installation.

By choosing Machine Matcher, you guarantee seamless buying, operational efficiency, and long-term reliability in your roll forming machine investment.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.