Posted on Wednesday, December 20, 2023

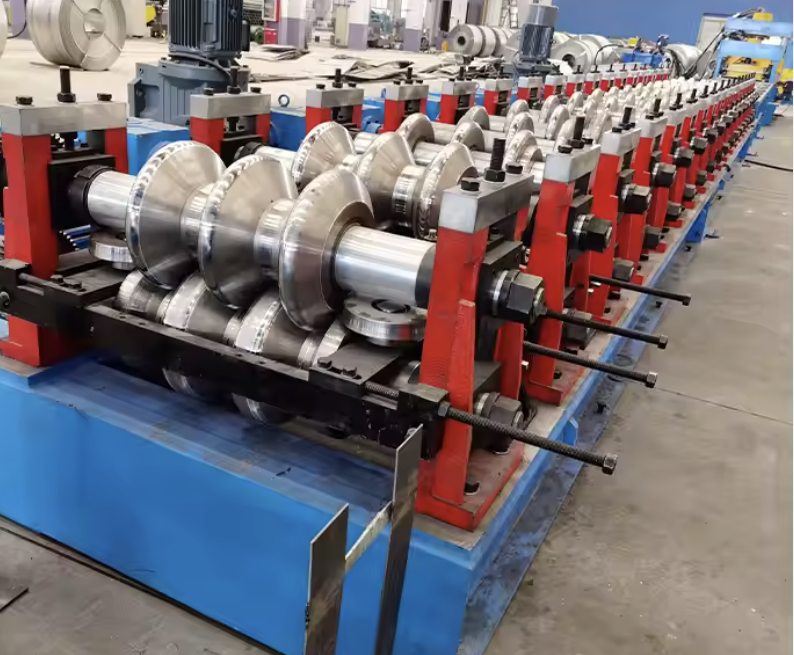

Myanmar’s construction and infrastructure sectors have seen rapid growth over the past decade, increasing the demand for high-quality roll forming machines. From roofing and cladding panels to purlins and structural components, roll forming machines are widely used across various industries in Myanmar. This guide explores the most popular roll forming machines in Myanmar, detailing their specifications, profiles, industries that use them, and more.

Specifications:

Roller Material: GCr15 steel with hard chrome plating

Frame Size: 300-450mm H-beam or welded steel

Motor: 5.5-11 kW depending on sheet thickness

PLC System: Siemens or Mitsubishi

Speed: 12-15 m/min

Hydraulic Cutting System: Post-cut, with automatic length measurement

Profiles Used:

Corrugated roofing sheets

IBR (Inverted Box Rib) sheets

Trapezoidal panels

Industries:

Residential and commercial roofing

Industrial warehouses and agricultural structures

Specifications:

Roller Material: Cr12 with heat treatment

Frame Size: 350-500mm H-beam

Motor: 11-15 kW depending on material thickness

PLC System: Delta or Siemens

Speed: 15-18 m/min

Hydraulic Cutting System: Servo-driven for precision cutting

Profiles Used:

C-channel and Z-channel purlins

U-shaped channels

Industries:

Structural framework for commercial buildings

Industrial facilities and storage sheds

Specifications:

Roller Material: Cr12MoV for high wear resistance

Frame Size: 400-600mm H-beam

Motor: 18.5-30 kW

PLC System: Siemens with HMI interface

Speed: 8-12 m/min

Hydraulic Punching and Cutting System

Profiles Used:

W-beam guardrails

Thrie-beam guardrails

Industries:

Highway safety and road construction

Specifications:

Roller Material: GCr15, heat-treated

Frame Size: 450-600mm H-beam

Motor: 15-22 kW

PLC System: Mitsubishi or Siemens

Speed: 12-15 m/min

Hydraulic Cutting System: Automatic, with PLC control

Profiles Used:

Floor decking profiles for multi-story buildings

Ribbed and trapezoidal steel decking

Industries:

Commercial construction

Industrial infrastructure

Yangon – Myanmar’s economic hub, where most large construction and manufacturing projects are based.

Mandalay – A center for industrial growth, with an increasing number of factories and workshops.

Naypyidaw – The capital city, witnessing major governmental and infrastructure projects.

Bago and Taunggyi – Emerging industrial zones where roll forming machines are used extensively.

Regular Lubrication: Lubricate bearings, rollers, and chains to prevent wear.

Alignment Check: Regularly inspect roller alignment to ensure consistent profiles.

Hydraulic System Inspection: Check for leaks and ensure proper fluid levels.

PLC and Electrical Maintenance: Ensure software updates and inspect wiring for faults.

Blade and Cutting System Maintenance: Sharpen blades and check for worn-out cutting systems.

Roofing Sheet Roll Forming Machines: $18,000 - $45,000

Purlin Roll Forming Machines: $30,000 - $70,000

Highway Guardrail Roll Forming Machines: $70,000 - $150,000

Metal Deck Roll Forming Machines: $40,000 - $90,000

While Myanmar has limited domestic manufacturers, most roll forming machines used in the country are imported from China, Taiwan, and India. Leading manufacturers include:

Botou Xianfa Roll Forming Machine Factory (China) – Known for high-quality roofing and cladding machines.

Hangzhou Zhongyuan Machinery Factory (China) – Popular for purlin and decking roll forming machines.

Yingkou Bohai Machinery Equipment Manufacture Co., Ltd. (China) – Recognized for guardrail and specialized roll forming machines.

Step 1: Install and level the machine on a solid foundation.

Step 2: Connect the machine to the appropriate power supply, ensuring compliance with voltage and phase requirements.

Step 3: Load the coil onto the uncoiler and align it properly with the feeding system.

Step 4: Configure the PLC system to specify length, profile dimensions, and cutting parameters.

Step 5: Conduct a test run to ensure proper alignment and profile accuracy.

Step 6: Start production and periodically monitor system performance.

Machine Matcher helps clients in Myanmar and worldwide purchase roll forming machines best suited for their profile needs. Our services include:

Inspection and Quality Assurance: We conduct thorough inspections before shipment to ensure compliance with quality standards.

Custom Machine Matching: We analyze your profile requirements and recommend the most suitable machine.

Shipping and Installation Support: We facilitate seamless delivery and assist with machine installation and commissioning.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Roofing and Cladding Panels: Used in commercial and residential projects.

Structural Components: Purlins and channels for industrial buildings.

Highway Safety Systems: Guardrails for highways and infrastructure.

Floor Decking Profiles: Ribbed and trapezoidal profiles for multi-story buildings.

Misaligned Profiles: Check roller alignment and adjust settings.

Inconsistent Lengths: Verify PLC programming and check cutting systems.

Excessive Wear on Rollers: Inspect lubrication and replace worn-out rollers.

Hydraulic System Failure: Ensure correct hydraulic fluid levels and check for leaks.

Material Restrictions: Most machines are designed for steel and aluminum and may not handle other materials well.

Profile Flexibility: Machines designed for specific profiles may not be easily reconfigured for other profiles.

Initial Investment: High upfront cost can be a barrier for small manufacturers.

High Efficiency and Speed: Consistent and rapid production with minimal errors.

Cost-Effective Production: Lower per-unit costs for high-volume production.

Precision and Consistency: Accurate profiles with minimal wastage.

Reduced Labor Costs: Automated processes reduce the need for manual labor.

Foundation and Leveling: Ensure a solid and level foundation for smooth operation.

Power Connection and Safety Checks: Verify electrical connections and install safety guards.

Test Run and Calibration: Conduct test runs to calibrate rollers and cutting systems.

Operator Training: Train operators to manage PLC systems and troubleshoot errors.

Operation: Consistent feeding, monitoring PLC settings, and ensuring proper coil handling.

Maintenance: Regular inspection of mechanical and electrical components to prevent downtime.

ISO 9001: Quality management standards for consistent production.

CE Marking: Compliance with European safety and environmental regulations.

ASTM Standards: Material specifications and tolerances for steel profiles.

UL Certification: Ensures electrical systems comply with international safety standards.

By working with Machine Matcher, you can ensure that you receive a high-quality, reliable roll forming machine that meets your profile and production requirements.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.