Posted on Monday, December 25, 2023

Senegal is experiencing a steady rise in infrastructure, industrial development, and residential construction. This growth has fueled demand for steel-based construction materials, making roll forming machines increasingly important in the local manufacturing and fabrication landscape. Whether for roofing panels, structural steel profiles, or decorative trims, roll forming machines are vital for producing high-quality metal components efficiently and at scale.

In this blog, we’ll explore the most popular roll forming machines in Senegal, including their types and specifications, the profiles they produce, the industries using them, and the cities where they are in high demand. We’ll also cover machine setup, maintenance, pricing, and how Machine Matcher can help you find the right machine for your specific needs.

Specifications:

Roller Materials: GCr15 steel with hard chrome coating

Frame: 350–450 H-beam welded structure

Motor Power: 5.5–15 kW

Control System: PLC with touch screen (typically Siemens or Delta)

Cutting Type: Hydraulic shearing system

Speed: 8–15 meters per minute

Profiles Produced:

Corrugated sheets

IBR profiles

Trapezoidal roofing panels

Industries:

Residential construction

Commercial roofing

Rural building projects

Popular Cities & Areas:

Dakar

Thiès

Saint-Louis

Touba

Ziguinchor

These machines are crucial for producing roofing sheets used across Senegal, especially in urban development and affordable housing projects.

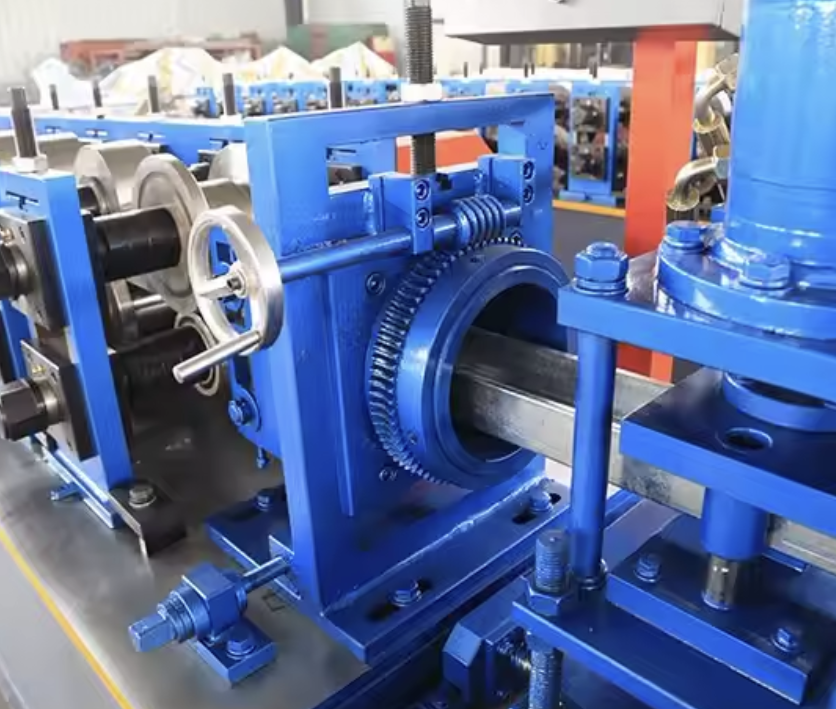

Specifications:

Roller Stations: 18–24

Thickness Range: 1.5–3.0 mm

Width Adjustment: Manual or fully automatic

Drive Type: Chain or gear-driven

Cutting: Hydraulic with flying saw or stop-cut system

Profiles Produced:

C-purlin

Z-purlin

U-channels

Industries:

Steel structures

Industrial warehouses

Agricultural buildings

Cities Using These Machines:

Dakar

Kaolack

Mbour

Richard-Toll

These machines help fabricate the structural backbone of steel-framed buildings and storage sheds, commonly used in agriculture and industry.

Specifications:

Roller Material: 45# steel with hardening

Drive System: Chain drive

Cutting: Hydraulic with die mold

Profile Length Accuracy: ±1 mm

Profiles Produced:

Ridge caps to cover roof apex

Hip covers for corner junctions

Industries:

Roofing and cladding

DIY and prefabricated buildings

Common Locations:

Suburban and rural regions outside Dakar

Tambacounda

Fatick

Ridge cap machines complement roofing sheet lines and are essential for water-resistant roof finishing in all climates.

Specifications:

Material Thickness: 0.4–0.8 mm

Rollers: 16–20 stations

Speed: 10–20 meters per minute

Hydraulic Cutter Power: 4 kW

Profiles Produced:

Round and rectangular gutters

Downpipes

Industries:

Rainwater management systems

Residential and industrial building construction

Demand Areas:

Dakar (urban drainage systems)

Touba

Rufisque

These machines are important for reducing flood risks by channeling rainwater efficiently from rooftops.

Specifications:

Servo Feeding System: Optional for accuracy

Profile Types: Frame, jamb, header

Material: Galvanized or cold-rolled steel

Automation Level: Semi or fully automatic

Profiles Produced:

Door frames

Window frames

Steel security door profiles

Industries:

Construction and prefabricated housing

Schools, hospitals, and government buildings

Popular Areas:

Urban and institutional projects in Dakar

Thiès

Ziguinchor

Construction and Infrastructure

The majority of demand for roll formed profiles comes from commercial and residential construction, especially in growing cities like Dakar and Touba.

Agriculture

Farms use roll-formed steel in structures like greenhouses, barns, and storage sheds.

Government and NGO Projects

Roll forming machines are used in building schools, clinics, and affordable housing—frequently supported by development aid.

Renewable Energy and Water Projects

Solar mounting bracket roll forming machines and water channel profiles are increasingly relevant.

Dakar – Capital city and industrial hub

Thiès – Transportation and infrastructure center

Saint-Louis – Coastal city with construction growth

Kaolack – Agricultural center needing storage sheds

Touba – One of the fastest-growing cities

Ziguinchor – Southern hub with rising demand

Installation

Set the base frame on a leveled concrete surface

Connect electrical and hydraulic systems

Install uncoiler and run test coils

Operation

Load coil material into the uncoiler

Calibrate profile settings through the PLC

Start the forming process with trial runs

Monitor and adjust speed and cutting precision

Training

Operators typically require 2–5 days of training on machine controls, material loading, and safety protocols.

Routine maintenance keeps roll forming machines in top shape:

Daily:

Clean rollers and guides

Check oil levels in hydraulic systems

Weekly:

Inspect chain drive or gearbox for wear

Lubricate all moving components

Monthly:

Calibrate PLC settings

Check for loose bolts, air leaks, and motor noise

Annually:

Replace hydraulic oil

Overhaul the electrical system

Perform precision alignment of rollers

Low-End Machines (Used or Manual Options):

Starting from $15,000 to $25,000

Common for basic corrugated sheet production

Mid-Range Machines (Semi-Automatic):

Ranges from $30,000 to $50,000

Popular for C/Z purlin and standard roofing lines

High-End Machines (Fully Automatic, Servo-Controlled):

$60,000 to $120,000+

Suitable for high-speed production or multiple profile capability

Pricing varies based on machine condition, automation level, profile complexity, and accessories.

While Senegal has a growing industrial sector, most roll forming machines are imported from countries like China, Turkey, India, and Europe. However, local integrators and distributors are available in cities like Dakar and Thiès.

Some Senegalese companies customize, maintain, or resell imported machines, but original manufacturing is limited.

Machine Matcher connects you with the right roll forming machine for your specific profile needs—whether you're a startup in Touba or a contractor in Dakar.

We help buyers in Senegal:

Choose the right machine based on power supply and profile specs

Compare new and used machine options

Arrange international shipping and installation

Access expert advice from people who understand local and global markets

With a large database of machines and industry knowledge across Africa, we simplify your buying journey and ensure you get the right solution the first time.

Q1: Can I buy used roll forming machines in Senegal?

Yes, many businesses in Senegal start with used machines to reduce initial investment. Machine Matcher can source reliable used machines for you.

Q2: What power supply do these machines use in Senegal?

Most machines operate on 380V, 50Hz three-phase power. Always confirm your factory’s supply before buying.

Q3: How long does it take to receive and install a machine?

Delivery typically takes 6–10 weeks, including ocean freight and customs. Installation can be completed in 3–7 days with trained technicians.

Q4: Do I need technical staff to operate the machine?

Yes, at least one trained operator is recommended. Machine Matcher can help organize training with the supplier.

Q5: Can I customize the machine for my profile?

Absolutely. Whether it's a unique roofing panel or purlin size, machines can be tailored to your drawing and gauge needs.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Let Machine Matcher guide you to the ideal roll forming machine for your business in Senegal.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.