Posted on Wednesday, January 10, 2024

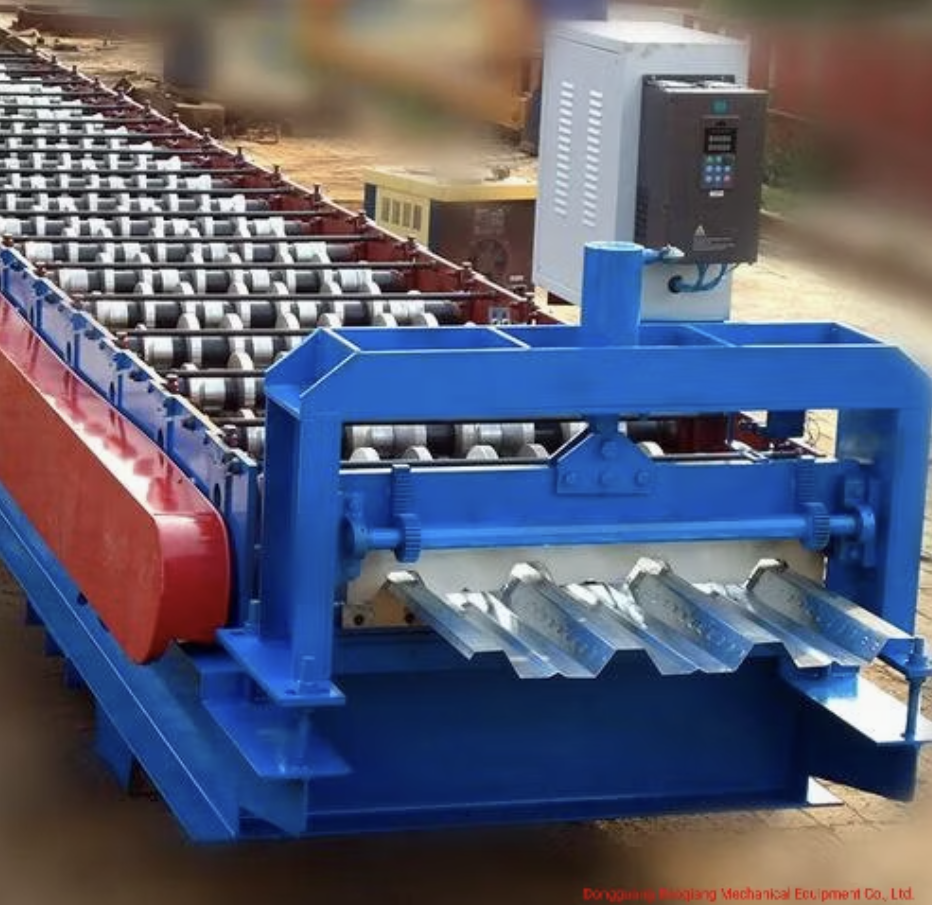

Latvia’s growing manufacturing industry has witnessed a significant increase in the use of roll forming machines. With a strategic location in the Baltic region and an emerging metal fabrication sector, Latvian industries rely on high-quality roll forming machines to produce roofing panels, steel frames, construction profiles, and other metal components. In this blog, we will explore the most popular roll forming machines in Latvia, providing detailed specifications, profiles used, industries that benefit from these machines, and an in-depth look at maintenance, troubleshooting, and setup.

Additionally, we will explain how Machine Matcher can help buyers and manufacturers in Latvia ensure quality inspections and make the best purchasing decisions.

Specifications:

Roller Material: High-grade steel with hard chrome coating

Frame Size: 300-450 H-beam structure for stability

Cutting System: Hydraulic cutting with high precision

PLC System: Programmable with touch screen and remote access

Motor Power: 5.5 kW – 15 kW depending on sheet thickness

Forming Speed: 12-15 m/min for standard production

Profile Sizes: 0.3 mm to 0.8 mm sheet thickness

Profiles Used:

Corrugated panels

Trapezoidal sheets

Standing seam panels

Industries:

Residential and commercial construction

Industrial roofing projects

Agricultural storage units

Main Cities and Areas Using These Machines:

Riga, Daugavpils, Liepāja, Jelgava, and Ventspils are the primary industrial hubs where roll forming machines are extensively used.

Specifications:

Roller Material: GCr15 steel with heat treatment

Frame Structure: Welded steel frame with tempering treatment

Cutting Type: Hydraulic pre-cut and post-cut

Motor Power: 11-18.5 kW depending on profile size

Forming Speed: 8-12 m/min

Profile Sizes: 1.5 mm to 3.0 mm steel thickness

Profiles Used:

C-purlins and Z-purlins for steel structures

Industries:

Industrial warehouses

Agricultural structures

Prefabricated buildings

Main Cities and Areas Using These Machines:

Riga and Liepāja house major steel fabricators and construction companies using C and Z purlin machines.

Specifications:

Roller Material: 45# steel with hard chrome plating

Frame Size: Heavy-duty steel frame for stability

Hydraulic Cutting System: High precision with automatic cutting

Motor Power: 18.5 kW – 37 kW depending on profile type

Forming Speed: 10-15 m/min

Profile Sizes: 2 mm to 4 mm thickness

Profiles Used:

W-beam guardrails

Thrie-beam guardrails

Industries:

Highway and road safety infrastructure

Government projects

Private contractors and engineering firms

Main Cities and Areas Using These Machines:

Riga, Jelgava, and other regions involved in large-scale infrastructure projects.

Specifications:

Roller Material: Cr12 with heat treatment for durability

Frame Structure: Rigid steel frame with automatic alignment

Motor Power: 7.5-15 kW depending on door size

Forming Speed: 10-20 m/min

Profile Sizes: 1.0 mm to 1.5 mm thickness

Profiles Used:

Steel door frames

Window frames

Industries:

Commercial and residential building industries

Prefabrication industries

Main Cities and Areas Using These Machines:

Riga, Ventspils, and Jelgava, where metal fabrication is prominent.

Regular maintenance is essential for ensuring optimal performance and extending the lifespan of roll forming machines. Key maintenance tasks include:

Lubrication: Regularly lubricate rollers, chains, and gears to prevent wear and tear.

Alignment Checks: Inspect roller alignment to avoid uneven profiles and material deformation.

Hydraulic System Inspection: Check for oil leaks and maintain proper hydraulic pressure.

PLC System Maintenance: Update software and calibrate the system periodically.

Cleaning: Clean the machine after each operation to prevent buildup of debris that may affect performance.

Roofing and Cladding: Used in residential, commercial, and industrial sectors.

Structural Components: C and Z purlins for prefabricated buildings and warehouses.

Guardrails and Safety Barriers: For highway and road safety projects.

Door and Window Frames: Widely used in construction and prefabrication.

Material Jamming: Check material thickness and roller alignment.

Inconsistent Profiles: Inspect roller spacing and ensure correct calibration.

Hydraulic System Failure: Check for leaks and maintain oil levels.

PLC System Errors: Verify software settings and restart the system.

Cutting Inaccuracy: Adjust blade alignment and hydraulic cutting pressure.

Limited Profile Variety: Roll forming machines are optimized for specific profiles, making quick design changes difficult.

Material Thickness Restrictions: Machines are often limited to certain sheet thicknesses.

High Initial Investment: High-quality machines with automation features require a significant upfront cost.

High Production Speed: Consistent and fast production with minimal manual intervention.

Cost-Effective: Low operational costs with minimal waste.

Customizable Profiles: Ability to create customized profiles suited to diverse industries.

Durability and Longevity: Machines built with high-grade materials ensure long operational life.

Site Preparation: Ensure the foundation is level and the environment is dust-free.

Machine Assembly: Assemble the frame, rollers, and cutting system.

Power Supply Connection: Connect appropriate voltage to meet machine specifications.

Trial Run: Perform a trial run with sample material to ensure accurate profile formation.

Calibration and Fine-tuning: Adjust machine settings for optimal performance.

Daily Operations: Monitor roller alignment and system performance.

Routine Cleaning: Clean rollers and remove any debris after operations.

Hydraulic System Checks: Monitor oil levels and pressure regularly.

Software Updates: Update the PLC system for enhanced control and automation.

ISO 9001: Ensuring quality management in manufacturing.

EN 10162: Cold-rolled steel sections for industrial applications.

CE Certification: Ensuring compliance with EU safety and operational standards.

Roofing Sheet Roll Forming Machines: $30,000 – $80,000

C and Z Purlin Roll Forming Machines: $45,000 – $100,000

Highway Guardrail Roll Forming Machines: $90,000 – $150,000

Door Frame Roll Forming Machines: $25,000 – $70,000

Riga Metalworks Ltd: Specializes in roofing sheet and guardrail roll forming machines.

Latvian Steel Machinery: Provides purlin and structural profile forming machines.

BALTIC Machines: Offers customized roll forming solutions for various industries.

Machine Matcher provides a comprehensive platform to help buyers in Latvia choose the best roll forming machines to suit their profile needs. Our experts assist with:

Profile and Specification Matching: Ensure that the machine meets the required profile dimensions and specifications.

On-Site and Remote Inspections: We offer detailed inspection services to assess machine quality, operational performance, and compliance with safety standards.

Expert Guidance: Our team guides you through the entire purchasing process, from initial inquiry to final delivery.

After-Sales Support: Assistance with setup, calibration, and operational training to ensure seamless integration into your production line.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.