Posted on Wednesday, January 17, 2024

Roll forming machines are essential in Malaysia’s manufacturing and construction industries, enabling the mass production of metal profiles used in roofing, cladding, structural components, and more. As Malaysia's construction and industrial sectors grow, the demand for roll forming machines has increased, with businesses seeking reliable solutions that meet their production needs efficiently. This guide explores the most popular roll forming machines in Malaysia, including their types, specifications, profiles, industries, regions of usage, and detailed insights into setup, operation, maintenance, and troubleshooting.

We’ll also cover the benefits, limitations, pricing, and how Machine Matcher can assist with inspections and purchasing to ensure you select the best roll forming machine for your needs.

The most popular roll forming machines in Malaysia include:

Specifications:

Roller Material: High-grade steel with chrome coating

Frame Size: 300-400mm H-beam frame for durability

Motor: 5.5-7.5 kW motors depending on machine speed

PLC System: Fully automated control with touch screen interface

Machine Speed: 15-20m/min

Safety Features: Emergency stop system and safety guards

Profiles Used:

Trapezoidal roof panels

Corrugated roof sheets

Purlin bearing rib (PBR) panels

Industries Using This Machine:

Construction and building sector

Roofing manufacturers

Prefabricated building companies

Specifications:

Roller Material: High-strength GCr15 steel

Frame Size: 350-500mm H-beam frame

Motor: 7.5-11 kW with variable speed control

Hydraulic Cutting System: Precise post-cutting with hydraulic drive

PLC Control: Fully automated with error detection system

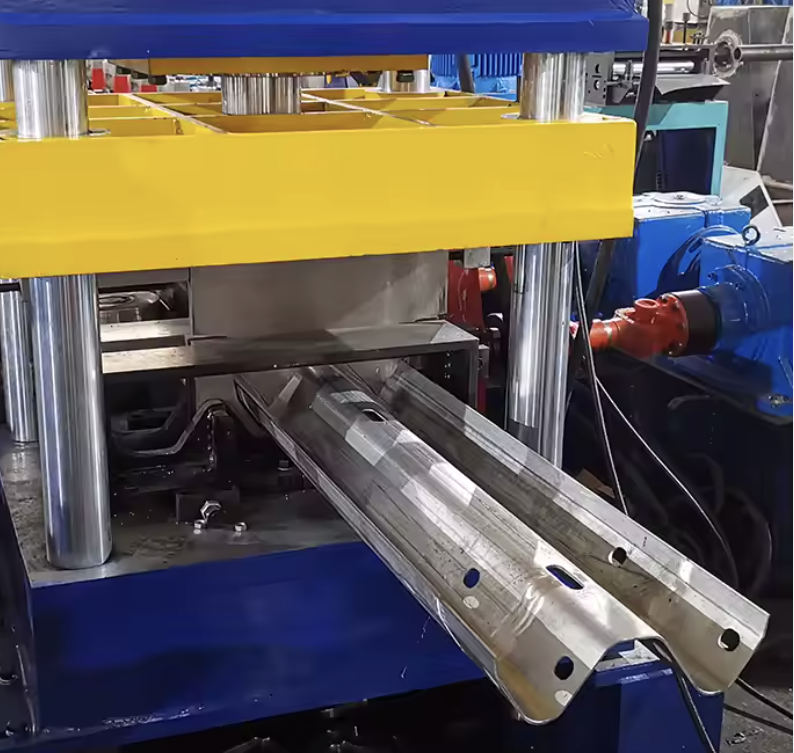

Profiles Used:

C and Z purlins

Channel sections

U-shaped structural profiles

Industries Using This Machine:

Structural steel manufacturers

Warehousing and industrial projects

Commercial and residential building contractors

Specifications:

Roller Material: Heat-treated and precision-ground steel

Frame Size: 350-450mm H-beam

Motor: 11-15 kW with adjustable speed control

Hydraulic Cutting: Accurate and burr-free cutting

PLC System: Siemens/Delta PLC system for consistency

Profiles Used:

Floor deck profiles

Ribbed metal decking

Steel reinforcement profiles

Industries Using This Machine:

Commercial and residential construction

Bridge and infrastructure projects

Multi-story building developers

Specifications:

Roller Material: GCr15 steel, heat-treated for durability

Frame Size: 450-600mm H-beam

Motor: 15-20 kW, suitable for heavy-duty production

Cutting System: Hydraulic cutting with automatic post-cut feature

PLC System: Advanced PLC for precision and minimal errors

Profiles Used:

W-beam and thrie-beam guardrails

Crash barriers

Safety barriers

Industries Using This Machine:

Road and highway safety projects

Municipal infrastructure development

Traffic management companies

Kuala Lumpur: High demand for roofing panels, guardrails, and structural profiles due to extensive construction projects.

Penang: Manufacturing and industrial hubs require purlins and decking profiles for factories and warehouses.

Johor Bahru: Heavy construction and infrastructure projects drive demand for C/Z purlin and floor deck machines.

Selangor: Growth in commercial construction creates a demand for versatile roll forming machines.

Roofing and Cladding: Widely used for producing durable metal sheets and roofing materials.

Structural Framing: Manufacturing of purlins and channels for industrial buildings.

Decking Systems: Used in multi-story buildings and commercial structures.

Highway Safety Systems: Producing guardrails and crash barriers for road safety.

Machine Setup:

Install the machine on a level foundation.

Connect power supply (usually 380V, 50Hz).

Load the coil material and align it with the rollers.

Operation Process:

Set profile dimensions through the PLC system.

Start the decoiler and feeding system.

Monitor roller movement and adjust speed if necessary.

Cut profiles to the required lengths using the hydraulic cutter.

Daily Maintenance:

Clean and lubricate rollers and chains.

Inspect for loose screws and bolts.

Weekly Maintenance:

Check hydraulic oil levels.

Inspect cutting blades for sharpness.

Monthly Maintenance:

Calibrate PLC system and sensors.

Examine bearings and replace if worn.

Profile Misalignment:

Check roller alignment and adjust settings.

Uneven Cutting:

Inspect and sharpen cutting blades.

PLC Malfunctions:

Reprogram or reset PLC parameters.

Profile Constraints: Some machines are limited to specific profile dimensions.

Material Compatibility: Not all machines handle high-strength steel or thicker gauges effectively.

Initial Setup Time: Complex profiles require longer setup and adjustment.

High Production Speed: Continuous operation reduces downtime and maximizes output.

Precision and Consistency: Advanced PLC control ensures consistent quality.

Cost Efficiency: Lower material waste and reduced labor costs over time.

Customizable Profiles: Machines can be modified to produce multiple profiles.

Basic Roof Panel Machines: $20,000 to $50,000

C/Z Purlin Machines: $40,000 to $100,000

Deck Roll Forming Machines: $60,000 to $150,000

Highway Guardrail Machines: $80,000 to $200,000

JF Roll Forming Machinery: Leading provider of roof panel and C/Z purlin machines.

MCM Machinery: Specializes in high-capacity deck and structural roll forming machines.

Advance Roll Forming Technology: Offers customized solutions for complex profiles.

Pre-installation Preparation: Verify machine dimensions and space availability.

Machine Installation: Place on a leveled foundation and secure all components.

Electrical and Hydraulic Setup: Connect power, PLC systems, and hydraulic units.

Test Run and Calibration: Conduct trial runs to ensure profile accuracy.

Operator Training: Train staff to manage PLC settings and troubleshoot minor errors.

Regular Inspections: Monitor rollers, motors, and hydraulic units for wear and tear.

Calibration and Cleaning: Keep PLC parameters updated and clean rollers regularly.

ISO 9001: Ensures quality management and consistency.

EN 1090-2: Compliance with structural steel and aluminum standards.

ANSI Standards: Compliance with American safety and performance standards.

Machine Matcher is your trusted partner in sourcing the perfect roll forming machine that meets your profile requirements. Our services include:

Machine Inspection and Quality Control: We conduct thorough inspections to ensure compliance with international standards.

Tailored Buying Assistance: Our team analyzes your profile needs to recommend the most suitable machine.

Vendor Negotiation and Logistics Support: We negotiate with top manufacturers to get you the best pricing and ensure smooth delivery.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.