Posted on Saturday, February 17, 2024

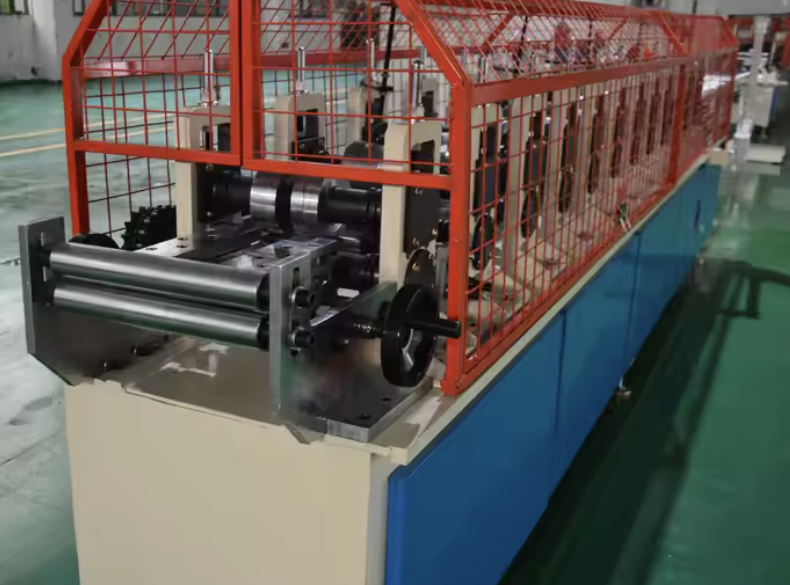

Roll forming machines play a vital role in Laos’s growing construction and infrastructure industry. With increased demand for steel profiles used in residential, commercial, and industrial projects, roll forming machines are being widely adopted in major cities such as Vientiane, Pakse, and Savannakhet. This guide explores the most popular roll forming machines in Laos, their specifications, typical applications, and the industries that use them. It also covers pricing, setup, operation, and maintenance, along with troubleshooting, limitations, and design standards. Finally, we explain how Machine Matcher can help buyers find the best roll forming machines for their specific profile needs.

Specifications:

Roller Material: High-grade 45# steel with hard chrome plating.

Frame: 16-20mm steel plate welded frame.

Motors: 5.5kW to 7.5kW motors.

PLC Control: Delta or Siemens PLC system.

Cutting System: Hydraulic cutting with automatic length control.

Speed: 10-15m/min.

Profiles Used:

Corrugated sheets

Trapezoidal roofing panels

Metal tile panels

Industries:

Residential and commercial roofing

Agricultural and warehouse buildings

Industrial facilities

Main Cities/Areas:

Vientiane, Pakse, Savannakhet, and Luang Prabang.

Specifications:

Roller Material: GCr15 steel with heat treatment.

Frame: 18-20mm steel plate.

Motors: 7.5kW to 15kW motors.

Punching and Notching: Hydraulic punching with inline notching.

PLC System: Panasonic or Siemens PLC control.

Speed: 15-20m/min.

Profiles Used:

C and Z purlins with adjustable sizes.

Thickness range: 1.5mm to 3.0mm.

Industries:

Steel structure construction

Prefabricated buildings

Industrial sheds

Main Cities/Areas:

Vientiane, Thakhek, and Pakse.

Specifications:

Roller Material: 45# steel with hard chrome coating.

Frame: Heavy-duty steel welded frame.

Motors: 11kW to 15kW motors.

Cutting System: Hydraulic cutting with automatic control.

Speed: 12-15m/min.

Profiles Used:

W-beam guardrails

Thrie-beam guardrails

Industries:

Highway and road safety projects

Government infrastructure projects

Main Cities/Areas:

Vientiane, Savannakhet, and Pakse.

Specifications:

Roller Material: High-quality steel with hard chrome coating.

Frame: Heavy-duty steel structure.

Motors: 5.5kW to 11kW motors.

PLC Control: Delta or Mitsubishi PLC.

Cutting System: Hydraulic cutting with automatic length measurement.

Speed: 10-15m/min.

Profiles Used:

Door frames and window profiles.

Various gauge thicknesses from 1.0mm to 2.5mm.

Industries:

Residential and commercial construction

Steel door and window fabrication

Main Cities/Areas:

Vientiane, Pakse, and Luang Prabang.

Roofing and cladding for residential, commercial, and industrial buildings.

Structural framing with C and Z purlins for steel construction.

Road and highway guardrails to enhance safety.

Door and window frame production for building projects.

Lubricate rollers and cutting blades.

Check the PLC control system for errors.

Inspect electrical components for any malfunctions.

Clean the roller stations to avoid dust buildup.

Inspect hydraulic oil levels in the cutting system.

Check gearboxes and chain drives for wear and tear.

Align rollers and adjust machine settings if needed.

Verify hydraulic pressure in the cutting system.

Roofing Sheet Roll Forming Machines: $25,000 to $50,000

C/Z Purlin Roll Forming Machines: $40,000 to $80,000

Highway Guardrail Roll Forming Machines: $60,000 to $120,000

Door Frame Roll Forming Machines: $30,000 to $60,000

Laos primarily imports roll forming machines from:

China: Leading suppliers include Botou Xianfa and Hangzhou Roll Forming.

India: Reliable manufacturers such as Metform and MTC.

Turkey: Popular brands like Digin and Samco.

Local manufacturers are limited, and most machines are imported to meet the growing demands of the construction industry.

Install the machine on a level surface.

Connect power supply and hydraulic systems.

Load steel coils onto the uncoiler.

Set profile dimensions and thickness on the PLC.

Adjust the roller alignment and punching/notching systems.

Run a test coil to verify profile accuracy.

Monitor the PLC system to ensure smooth operation.

Misalignment of Profiles: Check and adjust roller positions.

Hydraulic Cutting Failure: Inspect hydraulic oil levels and pressure.

PLC Control Errors: Reset the PLC system and check sensor connections.

Excessive Roller Wear: Replace worn rollers and lubricate moving parts.

Profile Customization: Limited to preset profiles without die changes.

Material Constraints: Not suitable for extremely thick or thin gauges.

High Initial Cost: High investment cost for imported machines.

Skilled Labor Requirement: Operators need training for PLC operation.

High Production Speed: Faster production rates than other metal forming processes.

Consistent Quality: Uniform profiles with minimal variations.

Reduced Waste: High material utilization with low scrap generation.

Customizable Profiles: Adaptable to different profile designs and thicknesses.

Anchor the machine to a concrete foundation.

Connect power, hydraulic, and pneumatic systems.

Install the uncoiler, feeding system, and cutting system.

Perform dry runs without coil to check alignment.

Load sample coil and adjust roller settings.

Test cutting accuracy and PLC settings.

Roll forming machines in Laos adhere to international design standards such as:

ISO 9001: Quality management standards.

CE Certification: Compliance with European safety standards.

ASTM Standards: Profile dimensions and material specifications.

Machine Matcher simplifies the process of buying roll forming machines by offering:

Profile and Size Matching: Helping you choose the best machine for your required profiles.

Machine Inspection: Ensuring quality through pre-shipment inspections.

Logistics Support: Assistance with shipping and delivery to Laos.

Technical Guidance: Post-installation technical support.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.