Posted on Wednesday, February 28, 2024

The Republic of the Congo is experiencing growing demand for metal construction products across its industrial, commercial, and infrastructure sectors. As steel usage expands throughout the country, roll forming machines are becoming essential for companies looking to produce precise metal profiles such as roofing sheets, structural components, cladding panels, and framing systems. This guide will explore the most popular roll forming machines used in the Republic of the Congo, including specifications, profiles, industry use, regional demand, maintenance tips, pricing, setup, and trusted suppliers.

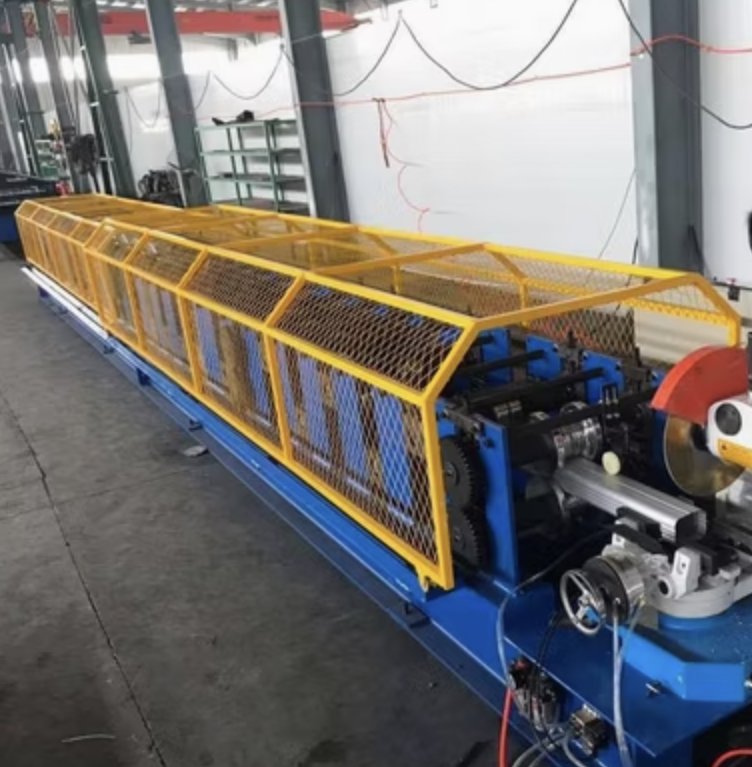

Description: These machines are used to manufacture trapezoidal, corrugated, and IBR metal roofing sheets.

Specifications:

Roller material: GCr15 with hard chrome plating

Motor: 7.5kW to 15kW

PLC system: Siemens or Delta

Forming stations: 12–20 rollers

Machine speed: 10–20 m/min

Material thickness: 0.3–0.8mm

Cutting: Hydraulic post-cut system

Common Profiles:

Corrugated (Sine wave)

IBR (Inverted Box Rib)

Trapezoidal panels

Industries:

Construction, residential housing projects, commercial buildings, agricultural sheds

Description: This machine forms steel purlins used as support structures in roofing systems.

Specifications:

Adjustable width: 80–300mm

Thickness range: 1.5–3.0mm

Punching system: Hydraulic with multiple hole patterns

Changeover: Manual or automatic type

Drive: Chain or gear

Industries:

Industrial warehouses, logistics buildings, solar structure framing

Description: Used to form steel frames for doors and windows.

Specifications:

Material thickness: 1.0–1.6mm

Frame sizes: Customizable

Cutting: Hydraulic

Control: Touchscreen PLC

Safety guards and emergency stop systems included

Industries:

Commercial and residential building projects, metal door manufacturers

Description: Produces W-beam and thrie-beam steel guardrails.

Specifications:

Thickness: 2.0–3.5mm

Material width: Up to 600mm

Output speed: 10–15 m/min

Hydraulic punching and cutting systems

Forming stations: 15–20

Industries:

Government infrastructure projects, road construction, civil engineering firms

Description: Creates the ridge caps used at the peak of roofs.

Specifications:

Material: Galvanized steel, aluminum

Thickness: 0.3–0.6mm

Rollers: 8–12 stations

Motor power: 5.5kW

Hydraulic cutter and manual decoiler

Industries:

Roofing contractors, home builders, hardware distributors

While infrastructure projects are developing across the country, the following cities and regions show the highest activity for metal forming:

Brazzaville – Commercial development, roofing, and civil infrastructure

Pointe-Noire – Port facilities, warehouses, logistics hubs

Dolisie – Residential building and public works

Ouesso – Infrastructure development and metal trade

Nkayi & Owando – Regional distribution and small-scale production

Proper maintenance ensures reliable production and extended machine life. Here's what Congolese operators and workshops should focus on:

Daily cleaning of rollers and forming stations to prevent material buildup

Lubricate chains and bearings every 1–2 days under high usage

Check hydraulic fluid levels weekly and replace filters as per manufacturer schedule

Inspect electrical components and tighten any loose wiring or sensors monthly

Recalibrate cutting units and blade systems regularly to maintain cutting precision

Prevent rust on frame and rollers during the humid season using anti-corrosion sprays

The cost of roll forming machines in the Republic of the Congo varies widely based on type, automation level, and configuration.

| Machine Type | Low-End Price (USD) | High-End Price (USD) |

|---|---|---|

| Roofing Sheet Machine | $18,000 | $60,000 |

| C/Z Purlin Machine | $25,000 | $80,000 |

| Door Frame Machine | $15,000 | $40,000 |

| Guardrail Machine | $45,000 | $110,000 |

| Ridge Cap Machine | $12,000 | $35,000 |

Note: Prices include basic decoilers and hydraulic cutting systems. Optional extras like auto stackers, servo feeding systems, or remote PLC monitoring will raise the cost.

Step-by-Step Setup:

Foundation preparation – Place machine on level surface with anchor bolts.

Uncoiler installation – Align coil stand with entry guide of roll former.

Power connection – Ensure correct phase and voltage (usually 380V/3P/50Hz in Congo).

Hydraulic unit setup – Fill oil reservoir, bleed air, test pressure levels.

PLC configuration – Input profile length, batch size, and hole punching parameters.

Trial run – Feed coil, run slow speed mode, check alignment and cuts.

Operator training – Teach safety protocols, emergency stops, and error codes.

Operation Tips:

Monitor material feeding for snags or misalignment

Use quality steel coils to avoid damaging the rollers

Always warm up the hydraulic system in cold weather

In the Republic of the Congo, there are few local manufacturers of roll forming machines. Most equipment is imported from:

Turkey – Mid-range machines with good service support

China – Widely used due to affordability and quick delivery

India – Value-focused machines with simple operation

Europe – High-end, precision roll formers with advanced PLC systems

Local distributors and resellers in Brazzaville and Pointe-Noire act as intermediaries and handle machine commissioning, after-sales service, and training. However, it’s important to ensure they offer genuine components and solid warranty terms.

At Machine Matcher, we specialize in connecting businesses in the Republic of the Congo with the right roll forming machines for their needs. Whether you're starting a roofing sheet business in Brazzaville or need a heavy-duty purlin line for Pointe-Noire, we help you:

Match machines to your exact profile drawings and material requirements

Choose between new or used equipment depending on your budget

Offer logistics and shipping assistance to Congo ports

Provide support with setup, operator training, and maintenance plans

Source machines from trusted manufacturers worldwide

Recommend cost-saving extras and automation upgrades

Our expert advisors are here to guide you from quote to operation.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Q1: What type of roll forming machine is best for metal roofing in Congo?

A1: A trapezoidal or corrugated sheet roll forming machine with 12–20 rollers, hydraulic cutting, and manual decoiler is ideal for roofing production in Brazzaville or Pointe-Noire.

Q2: Can I use Chinese-made machines in Congo?

A2: Yes. Chinese roll forming machines are popular due to their affordability and ease of operation. Ensure you purchase from a verified supplier with support options.

Q3: What voltage is typically required in Congo?

A3: Most industrial machines operate on 380V/3 phase/50Hz, but confirm with your local electrician before installation.

Q4: Are used roll forming machines a good option in Congo?

A4: Yes, especially for small to medium production. Used machines from Europe or India offer cost savings, but inspection and testing before purchase is crucial.

Q5: Do I need a skilled operator to run these machines?

A5: Basic training is sufficient for most models. However, machines with complex punching or servo systems may require experienced operators or additional training.

This blog provides a complete guide to the roll forming machine landscape in the Republic of the Congo. Whether you're a first-time buyer or an experienced fabricator, Machine Matcher is ready to help you find the right machine, with expert advice and reliable after-sales support.

Let us help you grow your business with the right machinery—designed for your profile, your industry, and your budget.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.