Posted on Friday, March 1, 2024

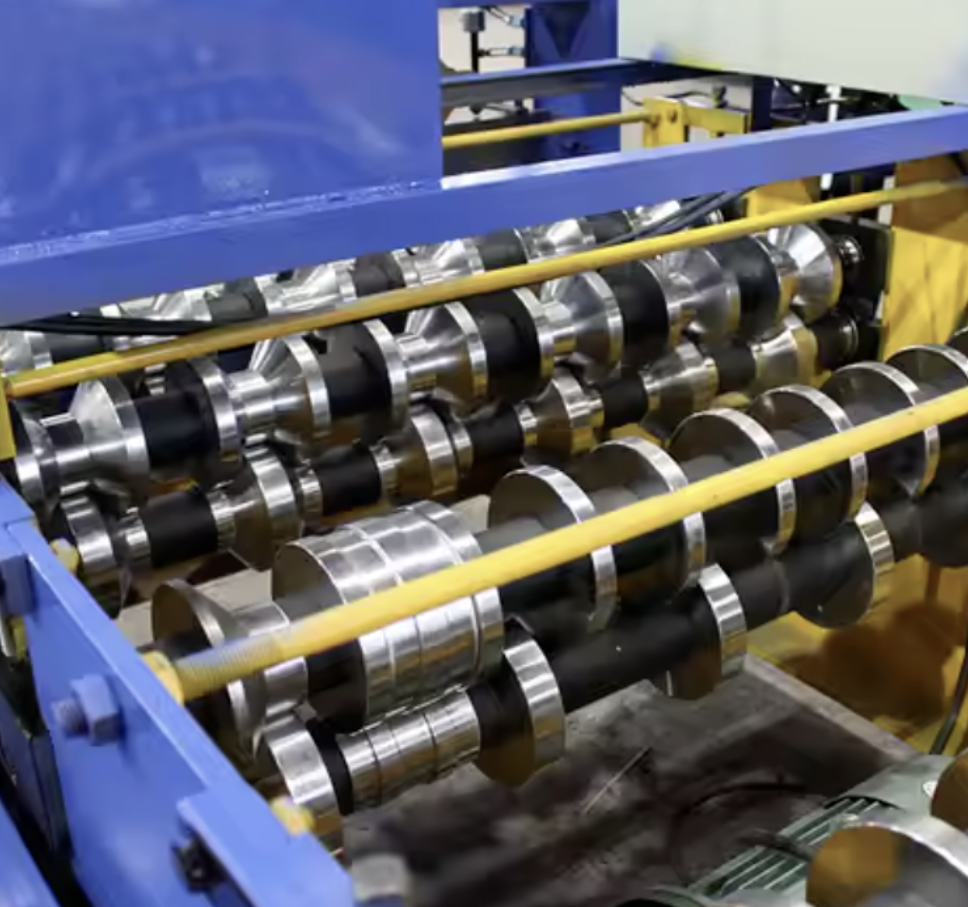

Roll forming machines have become an essential part of modern construction and manufacturing in Liberia. With infrastructure development increasing across key cities and industries, demand for high-quality, efficient, and durable roll forming machines is rising. From roofing sheet production to structural components, these machines support a wide range of applications.

In this guide, we’ll explore the most popular roll forming machines used in Liberia, including their specifications, the profiles they produce, industries using them, maintenance requirements, setup and operation, pricing, and more. We’ll also explain how Machine Matcher can help you choose the best machine for your specific profile and business needs.

Specifications:

Roller Material: GCr15 steel, hardened

Main Frame: 300–400 H-beam steel welded

Power Supply: 380V/50Hz/3Phase (customizable)

Motor Power: 5.5–7.5kW

Forming Stations: 16–22 stations

Cutting Type: Hydraulic post-cut

PLC System: Siemens or Delta

Used Profiles: IBR, corrugated, trapezoidal

Industries Using Them: Residential and commercial roofing, rural housing, construction supply businesses

Common Locations in Liberia: Monrovia, Buchanan, Ganta, Zwedru

Specifications:

Adjustable Rollers: Changeable from C to Z profile

Thickness Capacity: 1.5–3.0 mm

Profile Width: 80–300 mm

Main Motor Power: 15–22kW

Forming Speed: 10–15m/min

Punching: Hydraulic or servo punching units

Used Profiles: C and Z-shaped structural profiles

Industries Using Them: Steel building construction, warehouse structures, industrial buildings

Popular Areas: Monrovia Industrial Zone, Kakata, Gbarnga

Specifications:

Material Thickness: 0.4–0.7 mm

Material Width: 200–600 mm

Rollers: 12–18 stations

PLC System: Fully automated with touch screen

Speed: Up to 15m/min

Used Profiles: Half-round and box gutters

Industries Using Them: Roofing installers, housing contractors, rainwater system suppliers

Main Cities: Robertsport, Monrovia, Greenville

Specifications:

Material: Color steel, galvanized steel

Thickness: 0.3–0.6 mm

Stations: 12–16 rollers

Speed: 10–12m/min

Cutting System: Hydraulic

Used Profiles: Angular and curved ridge caps

Industries Using Them: Roofing component manufacturers, steel building contractors

Frequent Locations: Monrovia, Ganta, Kakata

Specifications:

Roller Stations: 18–24

Material Thickness: 0.8–2.0 mm

Speed: 8–15m/min

Motor Power: 7.5–15 kW

Automation: Servo-driven with punching and embossing

Used Profiles: Rolling shutter slats, steel door frames

Industries Using Them: Commercial property developers, industrial maintenance providers

Main Markets: Monrovia and surrounding suburbs

Proper maintenance is crucial to keep roll forming machines running efficiently. In Liberia’s humid and dusty environment, regular care becomes even more important.

Key Maintenance Tasks:

Daily Cleaning: Remove dust, debris, and leftover materials.

Lubrication: Apply oil to moving parts, rollers, and chains weekly.

Inspection: Check hydraulic oil levels, sensors, and wiring connections monthly.

Roller Alignment: Inspect and adjust alignment quarterly to prevent profile distortion.

Parts Replacement: Change worn-out bearings, seals, and blades as needed.

Scheduled preventive maintenance can reduce downtime, extend the machine’s life, and ensure product accuracy.

Pricing for roll forming machines in Liberia depends on the type, automation level, and profile size.

| Machine Type | Low-End Price (USD) | High-End Price (USD) |

|---|---|---|

| Roofing Sheet | $25,000 | $55,000 |

| C/Z Purlin | $45,000 | $85,000 |

| Gutter | $18,000 | $40,000 |

| Ridge Cap | $16,000 | $35,000 |

| Door Frame | $30,000 | $70,000 |

Low-cost machines are often semi-automatic with fewer features, while high-end models are fully automatic, include PLC controls, hydraulic units, and faster speed capabilities.

Setup Steps:

Foundation: Place the machine on a flat, reinforced concrete base.

Power Connection: Connect to the correct three-phase power supply.

Coil Loading: Mount the coil on the uncoiler or coil car.

Profile Calibration: Adjust rollers to match profile specifications.

PLC Programming: Set the length, cutting frequency, and batch count.

Trial Run: Test with sample coil before starting full production.

Operating Tips:

Always ensure material thickness matches machine capacity.

Follow safety protocols for handling hydraulic and electrical systems.

Use qualified operators trained in roll forming processes.

While Liberia has limited domestic manufacturing of roll forming equipment, most machines are imported from:

China: Major supplier of budget and mid-range machines

India: Known for structural profile machines and competitive pricing

Turkey: Supplies robust machines for roofing and gutter applications

Europe (Germany, Italy): High-end manufacturers with premium equipment

Local dealers in Monrovia and Freeport often act as resellers for these international manufacturers.

Q1: Can roll forming machines be customized for local profile needs in Liberia?

Yes. Most machines can be built to match the profile drawing or sample from your market. Custom tooling can also be created for special requirements.

Q2: How much space is required for a roll forming line?

Typically, 20 to 40 feet in length and 6 to 10 feet in width is needed. Allow additional space for coil handling and storage.

Q3: Can these machines run on a generator in areas without stable electricity?

Yes. Machines can run on industrial generators, but power stability is crucial to avoid system faults.

Q4: Is it easy to find spare parts in Liberia?

Common parts like motors, belts, and hydraulic components are available locally. Specialized parts can be imported within 7–14 days.

Q5: How long does shipping a roll forming machine to Liberia take?

Depending on origin, sea freight delivery to the Freeport of Monrovia typically takes 4–8 weeks.

Choosing the right roll forming machine can be complex, especially when trying to match profile requirements with budget and production volume. That’s where Machine Matcher comes in.

We specialize in sourcing, customizing, and delivering roll forming machines that are perfectly suited to your market and operational needs. Whether you're in Monrovia, Buchanan, Gbarnga, or any other part of Liberia, we help you:

Identify the ideal machine based on your profile and material

Compare multiple manufacturers and pricing options

Arrange shipping and delivery to your site

Get remote installation assistance and training

Source spare parts and provide after-sales service

With our global network and deep experience, we ensure you get the machine that matches your profile, your capacity, and your budget—no guesswork required.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.