Posted on Wednesday, March 6, 2024

The T purlin roll forming machine is one of the most specialized and sought-after solutions in the structural steel industry. Designed to produce T-shaped steel purlins, this machine offers accuracy, speed, and high productivity for a wide range of industrial and construction applications. In this article, we’ll take a deep dive into the full machine specifications, profile characteristics, popular markets, machine pricing, and how Machine Matcher can help you select the right equipment.

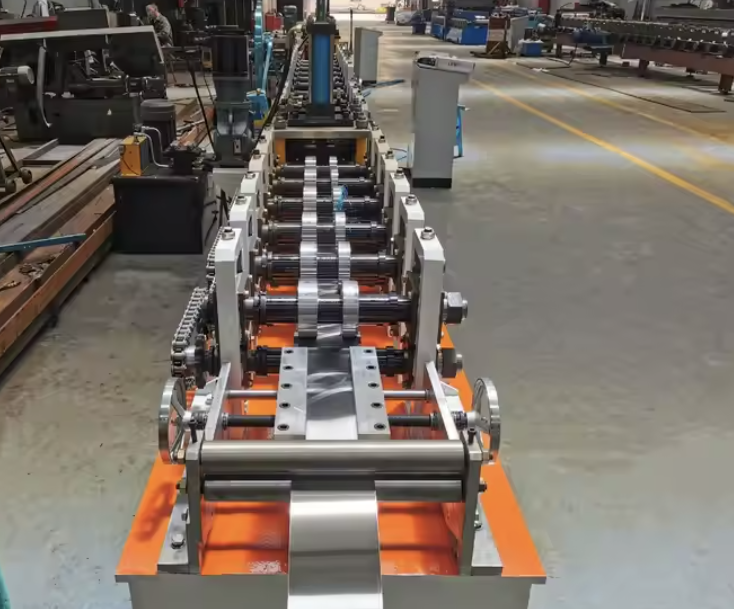

A T purlin roll forming machine is used to manufacture structural T-shaped metal profiles from galvanized steel or other coated steel coils. These profiles are used primarily in roofing and steel framing applications where central support is needed. The roll forming process uses a series of precisely machined rollers that gradually shape the metal into its final T-profile without heating or welding.

This machine is engineered for continuous, automated production with options for punching, notching, cutting, and stacking, delivering ready-to-install profiles with minimal manual handling. With various configurations available, it can be built for specific widths, heights, and thickness ranges, depending on the buyer's application needs.

Roller Materials

The rollers are typically made of high-grade GCr15 (bearing steel), hardened and polished for long life and accuracy. In some models, Cr12Mov material is used for extra wear resistance, especially in high-volume production.

Punching and Notching Units

CNC-controlled hydraulic punching and notching stations are integrated before or during roll forming, allowing for holes, slots, or other shapes as required for assembly or structural use.

Servo Motors

Servo motors are used to drive the punching and cutting stations with high precision. They ensure accurate positioning and synchronization with the PLC system to achieve perfect alignment.

Hydraulic Cutting System

T purlin machines come with a hydraulic post-cut system using Cr12 cutting blades, ensuring clean and burr-free cuts. The hydraulic unit is robust and designed for long operational life with minimal maintenance.

Frame Size

The machine base is usually made from heavy-duty H-beam steel, fully welded and stress-relieved to prevent warping. Frame sizes typically range from 300mm to 500mm width, depending on the profile.

Motors and Drive System

Equipped with branded motors (Siemens or equivalent), the drive system uses chain or gearbox transmission for powerful and stable forming performance.

PLC System

The heart of the machine is a fully integrated PLC control system (commonly Siemens, Panasonic, or Mitsubishi) with a user-friendly touchscreen HMI. It manages profile length, punching positions, speed, cutting, and automatic stacking.

Machine Speed

Standard forming speed ranges from 15–30 meters per minute. High-speed versions can reach up to 40 m/min, depending on profile complexity and extra functions.

Safety Guards and Enclosures

All moving parts are covered with safety enclosures or plexiglass covers to prevent accidents and ensure safe operation. Emergency stop systems are also included for immediate shutdown in case of issues.

Materials Used

Galvanized steel (G90, G60)

Cold-rolled steel

Pre-painted steel

Aluminum-zinc alloy coated steel

Sizes and Dimensions

T purlins are generally produced in widths from 50mm to 300mm with heights from 30mm to 100mm. Custom sizes can be configured as per architectural requirements.

Material Thickness

Common thicknesses range from 1.2mm to 3.0mm depending on structural load requirements.

Market Size and Applications

The T purlin profile is used in commercial roofing systems, prefabricated buildings, solar panel racking structures, sheds, and steel framing. It's especially suitable in areas requiring central roof support without obstructing headroom.

Industries That Use This Profile

Construction and structural steelwork

Solar mounting system manufacturers

Agricultural buildings

Industrial warehousing

Modular buildings

The T purlin roll forming machine is most popular in:

1. Middle East (UAE, Saudi Arabia, Qatar)

Used in massive infrastructure and roofing projects due to extreme weather-resistant framing.

2. India and Southeast Asia (Vietnam, Indonesia)

High demand from fast-growing industrial, solar, and prefabricated housing sectors.

3. North America (USA, Mexico)

Used for steel building frames, especially in commercial and agricultural projects.

4. Africa (South Africa, Nigeria, Kenya)

Cost-effective and durable T purlin structures are gaining traction in developing areas.

Why It's Popular

Versatile use in roofing and steel framing

Cost-efficient and lightweight alternative to I-beams

Easy installation and transportation

Customizable for different project sizes

You can configure a T purlin roll forming line with a range of automation options and accessories:

Stackers: Automatic profile stackers for quick unloading

Remote PLC Systems: For real-time remote monitoring and control

Coil Car Tippers: Simplify coil loading operations

Uncoilers and Recoilers: Hydraulic or manual, with load capacities from 3–10 tons

Automatic Stackers: Speed up downstream handling

Leveling System: Ensures flatness and eliminates coil memory before forming

Coil Handling Systems: Turnkey solutions for high-volume manufacturers

Prices vary depending on configuration, speed, and level of automation:

Basic Line (Manual): $35,000 – $50,000

Mid-Range (Semi-Automatic, with Punching): $55,000 – $80,000

High-End (Fully Automatic, with Servo Systems, Stackers): $90,000 – $130,000+

Custom options, tooling design, and support packages can also influence the final price.

Machine Matcher specializes in helping you find the right roll forming equipment for your production needs—new or used. With access to a wide network of manufacturers and ready-to-ship machines worldwide, we ensure:

Expert consultation to understand your profile and production requirements

Verified machines with full specifications and support

Logistics and delivery coordination across 170+ countries

After-sales support including installation, training, and spare parts

Flexible pricing options for every budget

We simplify the buying process, whether you need a standalone T purlin machine or a full production line.

Setting up a T purlin roll forming machine involves the following steps:

Foundation Preparation

A level, vibration-free concrete base is required.

Machine Placement and Alignment

All components (uncoiler, forming unit, hydraulic system, cutting unit) must be aligned in a straight line.

Electrical and Hydraulic Connections

Proper power supply and oil filling are necessary, matching the motor and hydraulic system specs.

Profile Testing and Calibration

A trial run is done using your coil material and profile drawing to calibrate the rollers, punches, and cutters.

Training and Commissioning

Operators are trained on the PLC interface, profile adjustments, safety protocols, and daily maintenance.

To keep your T purlin roll forming machine running at peak performance:

Daily cleaning of rollers and guides

Lubrication of moving parts per manufacturer schedule

Checking alignment of punches and cutters weekly

Replace hydraulic oil every 6–12 months

Routine electrical system checks

With proper care, the machine can run continuously for 10–15 years with minimal downtime.

Q1: Can the same machine produce multiple T purlin sizes?

Yes, with adjustable roller stations or cassette-type tooling, one machine can make various sizes.

Q2: What power supply is required?

Typically, 380V/50Hz 3-phase. Other voltages can be configured for different countries.

Q3: How long does it take to manufacture and ship this machine?

Standard production time is 30–60 days. Shipping depends on destination—usually 2–6 weeks.

Q4: What thickness range can this machine handle?

Standard machines work with 1.2–3.0mm. Heavier duty models can handle up to 4.0mm.

Q5: Is it possible to add automation later?

Yes, many systems like stackers and remote PLC upgrades can be retrofitted.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.