Posted on Wednesday, May 15, 2024

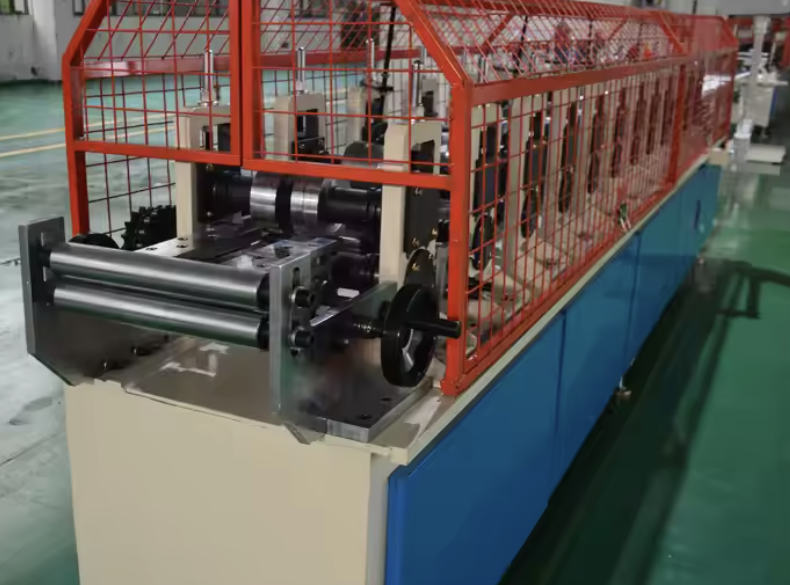

Burundi, a growing economy in East Africa, is gradually expanding its construction, infrastructure, and manufacturing sectors. One of the key drivers supporting this development is the increasing use of roll forming machines. These machines play a significant role in the local production of metal profiles for roofing, cladding, structural frameworks, and more.

In this article, we explore the most popular roll forming machines in Burundi, their specifications, the profiles they produce, the industries using them, key cities where they are commonly found, pricing ranges, maintenance tips, local setup and operation, and how Machine Matcher can help you find the right solution.

Specifications:

Rollers: GCr15 steel with hard chrome coating

Forming Stations: 12–20 depending on the profile

Material Thickness: 0.3–0.7 mm

Speed: 10–15 meters per minute

Motor Power: 5.5–7.5 kW

Cutting System: Hydraulic shearing

Used For: Corrugated, trapezoidal, and IBR roof sheets

Industries: Residential and commercial roofing, agricultural building construction

Specifications:

Roller Material: Cr12 with HRC58-62 treatment

Forming Stations: 15–20

Material Gauge: 1.5–3.0 mm

Adjustable Sizes: 80–300 mm width

Speed: 10–15 meters per minute

Motor Power: 11–15 kW

Used For: Structural support systems, wall frames, roof purlins

Industries: Industrial construction, warehousing, prefabricated structures

Specifications:

Rollers: High-grade steel with polishing

Forming Stations: 12–18

Material Thickness: 0.4–0.6 mm

Motor Power: 4–7.5 kW

Speed: 8–12 meters per minute

Used For: Half-round, box-type, and custom rain gutter profiles

Industries: Residential building construction, water management systems

Specifications:

Roller Material: GCr15 with hardening

Material Thickness: 0.4–0.7 mm

Power Supply: 380V, 3-phase or customizable

Speed: 10 meters per minute

Used For: Roof ridge closures and water-tight seals

Industries: Roofing, housing projects

Specifications:

Roller Stations: 16–22

Material Gauge: 1.0–2.0 mm

Motor Power: 11 kW

Speed: 8–12 m/min

Used For: Steel door frames, metal doors

Industries: Commercial construction, security infrastructure

IBR Sheets: For both residential and commercial roofing

Corrugated Panels: Low-cost roofing and cladding

C and Z Purlins: Structural supports for larger buildings

Rain Gutters and Ridge Caps: Roof finishing products

Door and Window Frames: For urban housing and commercial facilities

Construction and Roofing Companies

Pre-engineered Building Contractors

Agricultural Storage and Infrastructure

Government Projects (schools, clinics, public buildings)

Steel Product Fabricators

Bujumbura: The largest city and commercial hub where most machinery dealers and contractors are based

Gitega: The political capital, seeing rising infrastructure development

Ngozi and Ruyigi: Regional towns with growing demand for local construction material manufacturing

Rural Development Zones: Cooperatives and private firms investing in roofing and agricultural structures

Routine maintenance is crucial for keeping roll forming machines in excellent condition and maximizing their operational life.

Daily Cleaning: Remove dust and debris from rollers and machine bed

Lubrication: Weekly lubrication of bearings, gears, and chains

Roller Inspection: Check for wear or deformation every 30–60 days

Hydraulic System: Regularly monitor oil levels and change filters

Electrical Checks: Inspect PLC system and sensors monthly

Alignment Checks: Ensure profile accuracy and machine calibration quarterly

Preventive maintenance reduces downtime, saves costs, and extends machine lifespan.

Setting up a roll forming machine involves:

Unpacking and Positioning: Place the machine on a level surface with anchor bolts

Electrical Connection: Connect to the appropriate power supply (usually 380V/50Hz)

Hydraulic Setup: Fill and connect hydraulic pump if applicable

Material Feeding: Align coil material and guide it into the rollers

Trial Run: Run a test profile to ensure shape and cutting accuracy

Production: Once tested, continuous operation begins via the PLC system

Operator Training: A technician can train local staff in 1–2 days, covering machine use, adjustments, and basic troubleshooting.

The cost of a roll forming machine in Burundi depends on the machine type, automation level, and production speed.

| Machine Type | Low Cost (USD) | High Cost (USD) |

|---|---|---|

| Roof Panel Machine | $18,000 | $45,000 |

| C Purlin Machine | $25,000 | $60,000 |

| Gutter Machine | $12,000 | $28,000 |

| Ridge Cap Machine | $10,000 | $25,000 |

| Door Frame Machine | $20,000 | $50,000 |

Used machines are also available at lower prices, starting from around $7,000, but they may lack warranty or newer features.

While Burundi doesn’t have many domestic roll forming machine manufacturers, machines are primarily imported from:

China

India

Turkey

South Africa

Local resellers and construction equipment suppliers in Bujumbura and Gitega act as distribution points, offering setup and aftersales support.

However, choosing the right supplier is key. That’s where Machine Matcher comes in.

Machine Matcher connects you with the best roll forming machines suited to your needs — from new installations to second-hand systems. Here's why buyers in Burundi trust us:

Wide Inventory: Access machines for all profiles — roofing, purlins, gutters, trims, and more

Tailored Advice: We help match your profile drawing, material thickness, and power supply requirements with the perfect machine

Verified Sellers: We only work with trusted global manufacturers and quality used machine suppliers

Import Support: We guide you through importing machines into Burundi, including logistics, customs, and installation

Multilingual and Regional Support: Our team serves Africa, Europe, the USA, and beyond

Whether you're in Bujumbura, Gitega, or a remote province, Machine Matcher makes it easy to find a machine that meets your capacity, budget, and profile standards.

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Q1: Can I get a custom roll forming machine to match my unique profile in Burundi?

Yes. Machine Matcher works with suppliers who offer fully customized machines based on your profile drawing, material type, and size.

Q2: How long does it take to deliver a roll forming machine to Burundi?

Delivery can take 4–8 weeks depending on the machine’s origin. We can support with shipping and customs processes.

Q3: What power supply do these machines require in Burundi?

Most machines operate on 380V, 3-phase, 50Hz, which is compatible with Burundi’s industrial power grid. Alternative configurations are available upon request.

Q4: Can I buy used roll forming machines in Burundi?

Yes. Machine Matcher provides access to affordable, tested used machines with complete specs and images.

Q5: Do you provide on-site installation and training in Burundi?

We coordinate technician visits or offer remote video installation support depending on your location and machine type.

As Burundi continues to build its future, roll forming machines will remain critical to affordable, local construction and manufacturing. Whether you need roofing sheets, purlins, or door frames, having the right equipment is essential.

Let Machine Matcher help you find the best-fit roll forming machine — new or used — with full confidence and expert support.

Reach out today, and start producing high-quality profiles right here in Burundi.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.