Posted on Thursday, May 16, 2024

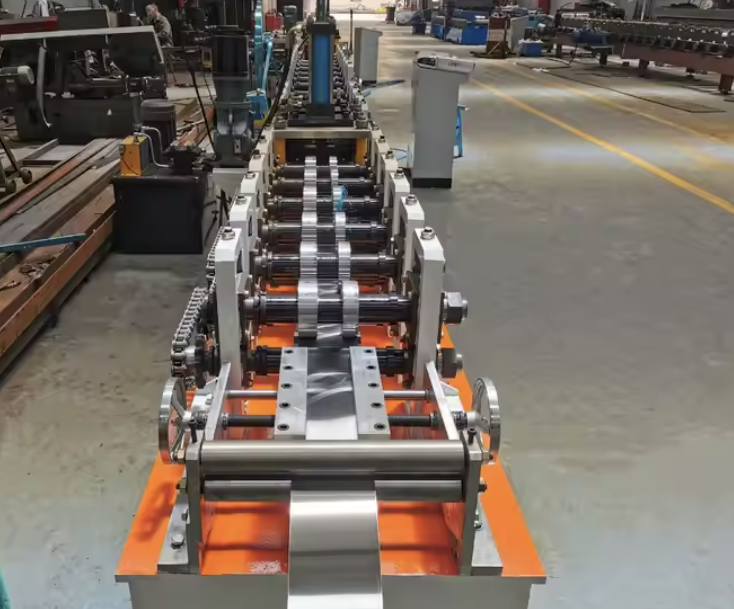

Rwanda, one of East Africa’s fastest-growing economies, continues to experience growth in infrastructure, construction, and manufacturing. As a result, roll forming machines have become vital tools across multiple industries in cities like Kigali, Huye, Musanze, and Rubavu. From producing roofing panels for residential and commercial buildings to manufacturing steel profiles used in agriculture and warehousing, roll forming machines in Rwanda are playing a key role in shaping the nation’s economic development.

In this article, we explore the most popular types of roll forming machines in Rwanda, including their specifications, profiles produced, common industries, key usage areas, maintenance requirements, pricing, setup, and more. If you're considering investing in a roll forming machine in Rwanda, this guide will help you make an informed decision.

Type: Corrugated, IBR, and Trapezoidal Panel Roll Forming Machines

Specifications:

Roller Material: GCr15 steel with hard chrome coating

Machine Frame: 300–450 H-beam structure

Cutting System: Hydraulic with Cr12Mov blades

PLC System: Siemens or Delta

Speed: 10–15 meters/min standard; high-speed options available

Material Thickness: 0.3mm – 0.8mm

Input Material: PPGI, GI, Alu-zinc, Aluminum sheets

Common Profiles:

Corrugated panels for low-cost housing

IBR panels for industrial and commercial roofing

Trapezoidal panels for mid-range buildings and warehouses

Industries:

Residential construction

Commercial roofing companies

Public infrastructure projects

Type: Adjustable C/Z purlin roll forming machines

Specifications:

Roller Material: High-grade steel with surface treatment

Thickness Range: 1.2mm – 3.0mm

Changeover System: Manual or automatic purlin size adjustment

Hydraulic Cutter: For post-cutting based on desired lengths

PLC Control: Fully automatic

Common Profiles:

C purlins used in roof trusses and wall frames

Z purlins for supporting structural loads in metal buildings

Industries:

Industrial buildings

Steel warehouses

Agricultural storage units

Specifications:

Material Thickness: 0.4mm – 0.7mm

Roller Stations: 16–20 stations depending on the profile

Drive System: Chain or gearbox

Power: 7.5kW main motor average

Profiles:

Half-round gutter

Box-style rain gutter

K-style gutter profiles

Industries:

Residential construction

Rainwater collection systems

Commercial property maintenance

Specifications:

Material: Galvanized steel and cold-rolled steel

Thickness Range: 0.8mm – 2.0mm

Features: Inline punching, notching, and cut-to-length systems

Drive System: Gearbox-driven with AC motors

Profiles:

Door jambs

Window frames

Roller shutter slats

Industries:

Commercial and residential doors

Security shutter manufacturing

Roll forming machines are actively used in several major Rwandan cities:

Kigali: The capital and industrial hub, with large-scale construction and warehousing projects

Huye: Growing demand for affordable housing and educational infrastructure

Musanze: Agricultural and commercial development needs metal roofing solutions

Rubavu: Rapidly expanding tourism industry needing durable, stylish building materials

Muhanga & Nyagatare: Regional construction activity is driving demand for roll formed panels and frames

To ensure roll forming machines operate efficiently, the following maintenance tasks are critical:

Daily Cleaning: Remove metal dust and debris from rollers and moving parts

Lubrication: Apply oil or grease to moving parts such as the chains, bearings, and gears

Roller Inspection: Check for wear, alignment, and cracks regularly

Hydraulic Oil Check: Change oil every 6–12 months and monitor the hydraulic system

Electrical Components: Inspect wiring and control panels for any signs of damage

Alignment Calibration: Ensure rollers are correctly aligned to avoid profile defects

Preventive maintenance helps reduce downtime and extends the machine’s operational lifespan.

Setup Steps:

Foundation Installation: Ensure a flat, stable base using concrete

Machine Positioning: Place the machine in line with uncoiler and output tables

Power Supply Check: Connect to local power grid (typically 380V, 50Hz 3-phase in Rwanda)

Profile Setup: Load coil material and set rollers to the desired profile

PLC Programming: Input cutting length, batch quantity, and punching positions if applicable

Trial Run: Perform test runs with sheet feeding and fine-tuning

Operation:

Start with the uncoiler feeding material

Sheets pass through forming rollers

Inline punching or embossing if needed

Cut to length by the hydraulic shear

Collect finished profiles on a run-out table or stacker

Roll forming machine prices in Rwanda can vary based on speed, automation level, and profile complexity:

| Machine Type | Entry-Level Price (USD) | High-End Price (USD) |

|---|---|---|

| Roofing Sheet Machine | $25,000 | $70,000 |

| C/Z Purlin Machine | $35,000 | $90,000 |

| Gutter Machine | $18,000 | $40,000 |

| Door Frame/Shutter Machine | $30,000 | $75,000 |

Entry-level machines are manually adjustable with basic PLCs, while high-end versions offer fully automatic systems, servo feeding, and inline punching.

Rwanda currently imports most of its roll forming machines, as there are few local manufacturers. However, the following companies are known suppliers or importers:

Construction supply companies in Kigali that source machines from Turkey, China, and India

Regional distributors based in Nairobi and Kampala also serve Rwanda

Direct importers bringing in machines tailored to local profile needs

Most businesses in Rwanda rely on sourcing roll forming machines through international platforms or direct contacts with global manufacturers.

Q: What is the most commonly used profile in Rwanda?

A: IBR and corrugated roofing panels are the most widely used profiles for both residential and commercial applications.

Q: Can roll forming machines in Rwanda handle thicker steel?

A: Yes, C/Z purlin machines and door frame machines can process steel up to 3mm thick, ideal for structural applications.

Q: Do I need a skilled operator to run these machines?

A: Yes, operators should be trained in machine setup, profile alignment, and PLC control. However, semi-automatic machines are easier to manage with minimal training.

Q: How do I choose the right roll forming machine for my business in Rwanda?

A: Consider your target profile, material type, production speed, available power supply, and whether inline punching or automation is needed.

Q: How long does delivery and setup take in Rwanda?

A: Shipping from international suppliers typically takes 6–10 weeks. Installation and commissioning can be done in 3–5 days once the machine arrives.

Machine Matcher specializes in connecting businesses in Rwanda with the ideal roll forming machine to meet their profile needs. Whether you require roofing panel machines, purlin lines, or gutter machines, we help you choose from new and used machines, compare global suppliers, and ensure you receive a machine suited to your budget and technical specifications.

Why choose Machine Matcher?

Access to a global inventory of machines

Assistance with profile drawings and custom profile matching

Options for both new and second-hand equipment

Shipping and setup support tailored for Rwandan buyers

Expert guidance in English, French, and Kinyarwanda-speaking regions

Speak to one of our roll forming machine experts today:

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Let Machine Matcher help you find the perfect roll forming machine for your business in Rwanda.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.