Posted on Tuesday, July 2, 2024

Standing seam panels have long been the gold standard in modern roofing, celebrated for their sleek design, durability, and exceptional weather resistance. Among these, Snaplock standing seam panels have emerged as a game-changer, redefining the roofing industry with their innovative design and installation advantages.

The origins of standing seam panels date back to the 18th century, where they were first used on prominent buildings in Europe. These early panels were manually seamed and labor-intensive to install, requiring skilled craftsmanship to achieve a weather-tight fit. Over time, technological advancements brought precision-rolled panels and mechanized seaming tools, paving the way for faster, more efficient installations.

Snaplock panels represent a significant leap in the evolution of standing seam roofing. Introduced to simplify installation without compromising the integrity and aesthetics of traditional standing seam systems, Snaplock panels quickly gained popularity among architects, contractors, and homeowners.

Snaplock panels have redefined roofing across multiple industries, including:

As the demand for sustainable and energy-efficient roofing systems grows, Snaplock panels continue to evolve. Advances in materials, coatings, and manufacturing techniques ensure that these panels remain at the forefront of roofing innovation.

With their ability to seamlessly blend traditional aesthetics with modern convenience, Snaplock panels are poised to play a key role in the future of roofing, offering solutions that are both practical and visually appealing.

Snaplock panels have truly redefined roofing, marrying centuries-old principles of standing seam design with cutting-edge innovation. Whether you’re a homeowner, contractor, or architect, Snaplock panels represent a roofing solution that stands the test of time—both in style and performance.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

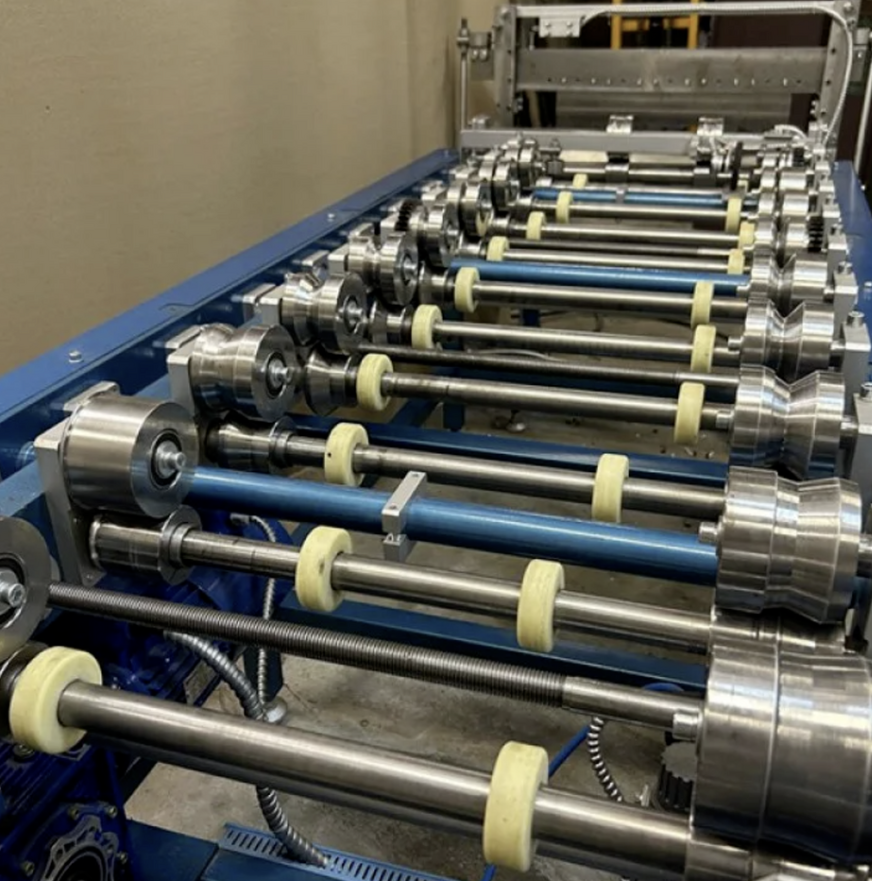

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.