Posted on Thursday, September 26, 2024

Ensuring Consistent Quality in Metal Drip Edge Manufacturing with Precision Roll Forming

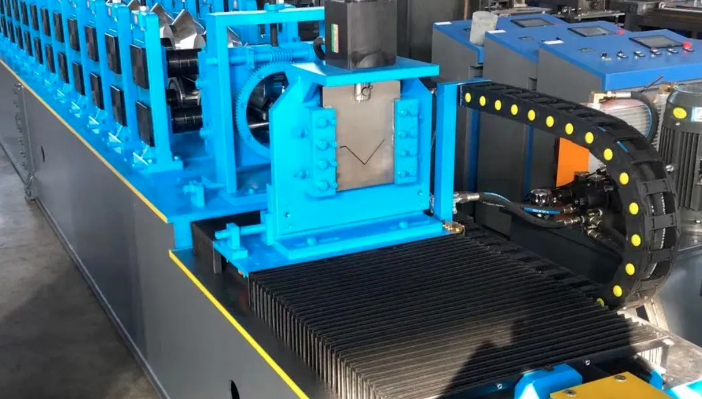

In the competitive world of roofing products, maintaining the highest quality standards is paramount. Metal drip edges, an essential component for protecting roofs from water damage, must be produced with precision and consistency. This is where advanced roll forming machines come into play, ensuring that each drip edge meets the exacting requirements of both contractors and industry standards.

Drip edges serve a crucial function by directing water away from the roof and fascia, preventing moisture infiltration that can lead to structural damage. Any deviation in the quality or dimensions of the metal drip edge can compromise its performance, leading to potential roofing failures. To ensure optimal performance, manufacturers must produce these components with tight tolerances and consistent quality.

Roll forming machines are the backbone of drip edge production, transforming flat metal coils into complex, continuous profiles. With the latest precision roll forming technology, manufacturers can:

Precision roll forming machines not only provide dimensional accuracy but also help in forming drip edges with enhanced durability. The controlled forming process ensures that the metal maintains its structural integrity, resisting deformation or cracks during installation or long-term use in harsh environmental conditions.

For manufacturers in the roofing industry, adopting precision roll forming machines is essential to ensuring the consistent quality and performance of metal drip edges. By leveraging this advanced technology, companies can meet industry standards, improve production efficiency, and provide roofing contractors with reliable, high-quality products that protect buildings from water damage for years to come.

Machine matcher specialise in matching your roll forming machine requirements with the perfect new or pre owned machine.

We partner with, and represent some of the finest roll forming manufacturers in the market. For more information and a free machine quote please contact us today or view all machines.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.