Posted on Monday, September 30, 2024

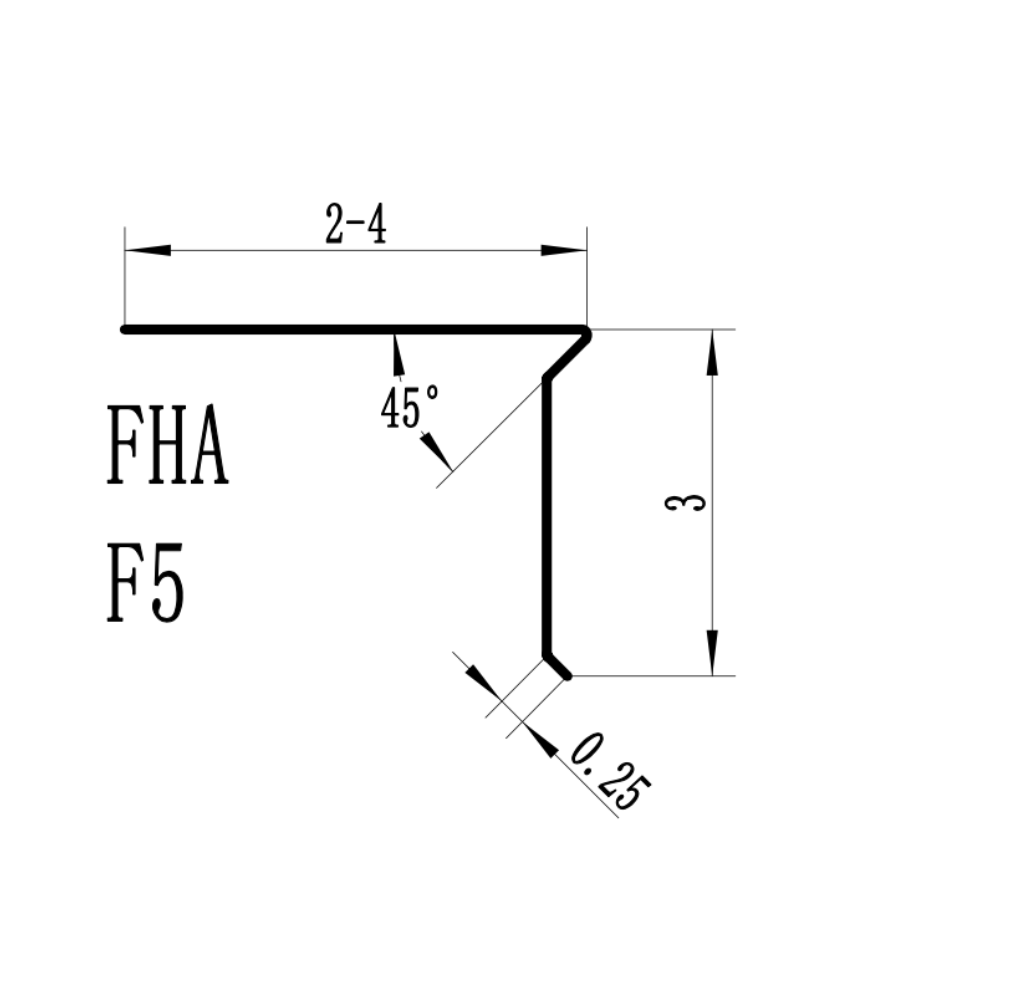

FHA F5 DRIP EDGE PROFILE DRAWING .png file | 543 KB

The FHA F5 Drip Edge Profile is a specific type of metal flashing commonly used on residential roofs to protect the edges of the roof from water damage. It helps to direct water away from the roof edge and into the gutters, preventing water infiltration under the roofing material and prolonging the roof's lifespan. This profile is widely used in both sloped and flat roof systems, especially for homes adhering to FHA (Federal Housing Administration) standards.

The F5 refers to the profile's specific dimensions, typically featuring a vertical face (around 1.5 inches) and a horizontal flange (5 inches), which provides ample coverage over the roof edge. This type of drip edge is often made from materials like galvanized steel, aluminum, or copper, and can come in various finishes to match the roof and enhance curb appeal.

To produce FHA F5 drip edge profiles, roll forming machines are ideal due to their precision, efficiency, and ability to handle high-volume production. Here’s how roll forming machines contribute to the manufacturing of drip edges like the FHA F5 profile:

Roll forming machines are customizable to produce specific profiles such as the FHA F5. These machines can be equipped with specially designed rollers that shape the metal coil into the exact dimensions of the F5 profile, ensuring consistency in every piece produced.

Roll forming machines can handle a wide range of materials used for drip edges, including:

Roll forming machines are capable of producing drip edge profiles at high speeds, making them suitable for manufacturers who need to meet large-scale demand quickly. The continuous feed of metal coil into the machine allows for the rapid production of long lengths without interruptions, ideal for roofing contractors who require large quantities.

Roll forming ensures uniformity across every piece of drip edge produced. The machine creates precise bends and cuts with minimal variation, critical for maintaining the integrity of the FHA F5 profile’s dimensions (5-inch flange and 1.5-inch vertical face). This consistency reduces installation time and ensures a proper fit across the entire roofline.

Modern roll forming machines are automated, meaning they require minimal manual intervention. This reduces labor costs while ensuring that the machines can run continuously, producing the desired profiles without errors.

These machines often come with an integrated cut-to-length feature, allowing the manufacturer to specify the exact length required for each piece of FHA F5 drip edge. This feature ensures that each piece is tailored to the exact specifications needed for different roofing projects.

Roll forming machines are highly efficient in their use of material. By precisely shaping the metal coil into the required profile, they minimize waste, which is particularly important for cost-effective production in large-scale projects.

Whether you’re a small business or a large manufacturer, roll forming machines can be scaled to meet your production needs. Manufacturers can adjust the machine settings for different lengths, profiles, or materials, making it easy to produce not only FHA F5 profiles but also other drip edge styles.

If you're considering investing in a roll forming machine to manufacture FHA F5 drip edges or other roofing components, there are machines specifically designed for drip edge production. These machines can be customized to your needs, helping your business meet roofing industry demands efficiently and cost-effectively.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.