Posted on Wednesday, September 18, 2024

Guide rail roll forming machine

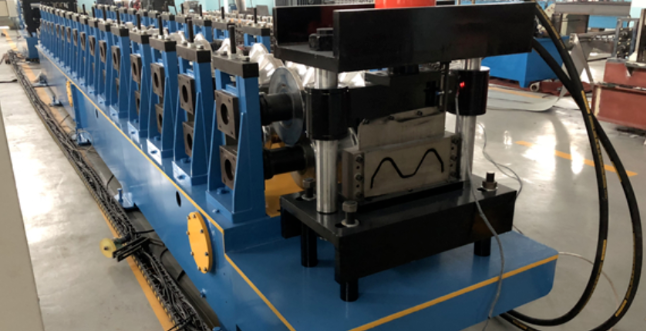

A guide rail roll forming machine is specifically designed to produce various types of guide rails, commonly used in industrial applications like conveyors, elevators, or safety railings. These machines offer precise forming capabilities for materials such as galvanized steel, stainless steel, or aluminum, and are ideal for creating custom profiles of guide rails to meet specific industry standards.

Guide rail profile

A guide rail profile refers to the specific shape and dimensions of the metal guide rails produced by a roll forming machine. These profiles vary depending on the application, such as elevator rails, conveyor system rails, or safety guardrails. The shape of the profile is designed to meet the structural and functional needs of its intended use.

Guide rail profiles are typically made from galvanized steel, stainless steel, or aluminum, depending on the strength, corrosion resistance, and weight requirements.

The profile design is crucial to ensure proper function, especially in dynamic systems like elevators or conveyor belts, where precision and durability are key.

If you’re looking for specific guide rail profiles or have a project requiring a custom rail design

Machine matcher specialise in matching your roll forming machine requirements with the perfect new or pre owned machine.

We partner with, and represent some of the finest roll forming manufacturers in the market. For more information and a free machine quote please contact us today or view all machines.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.